Fan-shaped permanent magnet-comprising dual-steady-state contactor

A contactor and bistable technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of low permanent magnet utilization, large space volume, slow response speed, etc., to improve the permanent magnet utilization, The effect of fast response speed and small ampere-turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

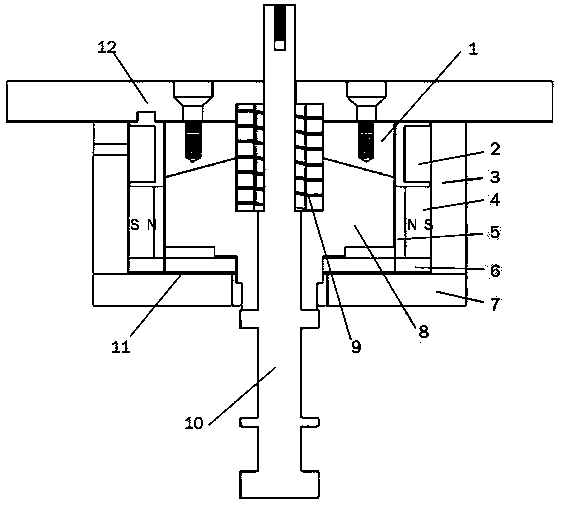

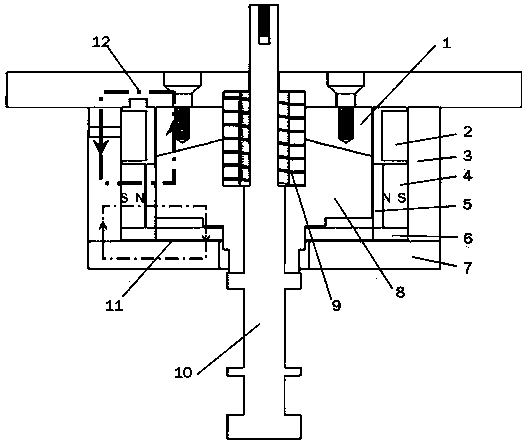

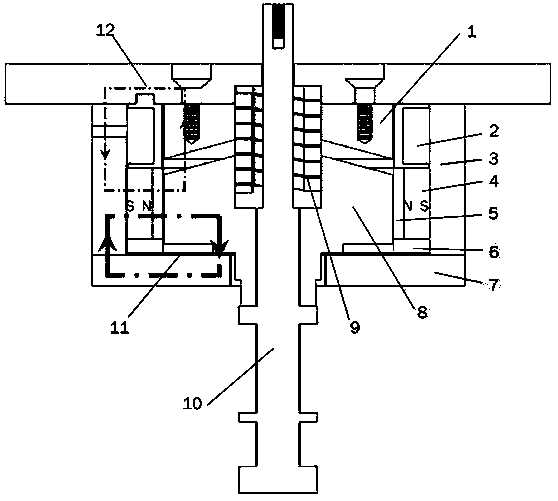

[0035] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] refer to figure 1 — Figure 7 , the present invention provides a bistable contactor with sector-shaped permanent magnets, including a static iron core 1, a coil 2, a casing 3, a permanent magnet 4, a magnetic ring 5, a spacer 6, a lower yoke 7, an armature 8, a Gate spring 9, push rod 10, spacer 11 and base 12;

[0037] The static iron core 1 is a cylinder with a hole in the center, its upper end surface is a plane, and fits with the lower surface of the base 10, and its lower end surface is a conical surface, which fits with the upper end conical surface of the armature 7, The static iron core 1 is fixed together with the base 10 by screws;

[0038] The upper end surface of the coil 2 is provided with a protrusion, which is fixedly connected with the groove on the lower end surface of the base 12; the coil 2 is located between the static iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com