Obstacle crossing mechanism for inspection of dual power transmission lines

A technology of power transmission lines and traveling mechanisms, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of overly large upper dimensions, excessive lower dimensions, and the inability of robots to pass through, so as to achieve simple movements, avoid shaking, and improve obstacle-crossing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

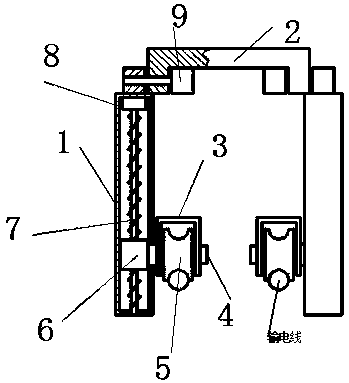

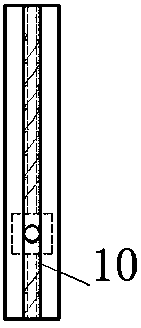

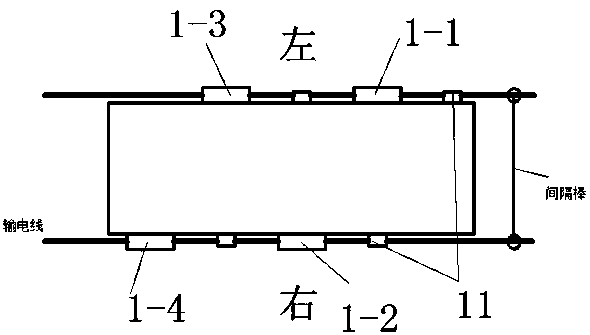

[0036] A double power line inspection obstacle clearance mechanism, which includes a body 2, the body 2 is set on the power line through a number of running gears arranged on both sides thereof, and the running gears on each side are all set on the same power line, Each walking mechanism includes a support arm 1 and a walking wheel 5; Relative displacement, the walking wheel 5 is arranged on the transmission line, drives the body 2 to move along the transmission line; the support arm 1 can swing forward or backward along the extension direction of the transmission line, so that the walking wheel 5 is lifted and separated from the transmission line ; In the extension direction of the power transmission line, the running gears on both sides of the body 2 are mutually misplaced, and the running gears on the same side are set at equal intervals.

[0037] The traveling wheels 5 can be arranged on the outside or inside of the support arm 1 , and in this embodiment, the traveling whe...

Embodiment 2

[0046] This embodiment is substantially the same as Embodiment 1, except that the distance between each running gear installation position and its opposite left adjacent running gear installation position and / or right adjacent running gear installation position is equal.

Embodiment 3

[0048] This embodiment is substantially the same as Embodiment 1, except that the distance between each running gear installation location and its adjacent running gear installation location is equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com