Coordinated motion synchronous control method for double-robot mirror milling and equal wall thickness machining

A technology of mirror milling and dual robots, which is applied in automatic control devices, metal processing, metal processing equipment, etc., can solve the problems of poor adaptability, high production cost of special fixtures, and large size of five-axis CNC machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

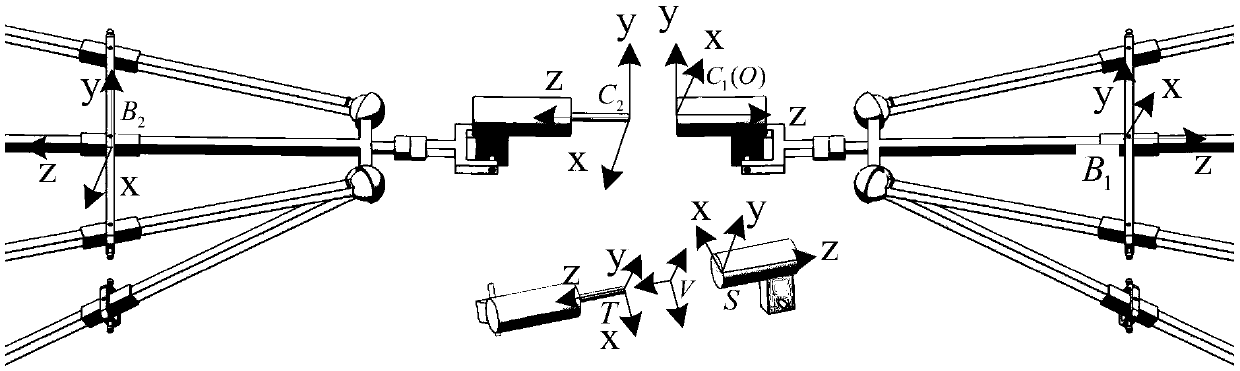

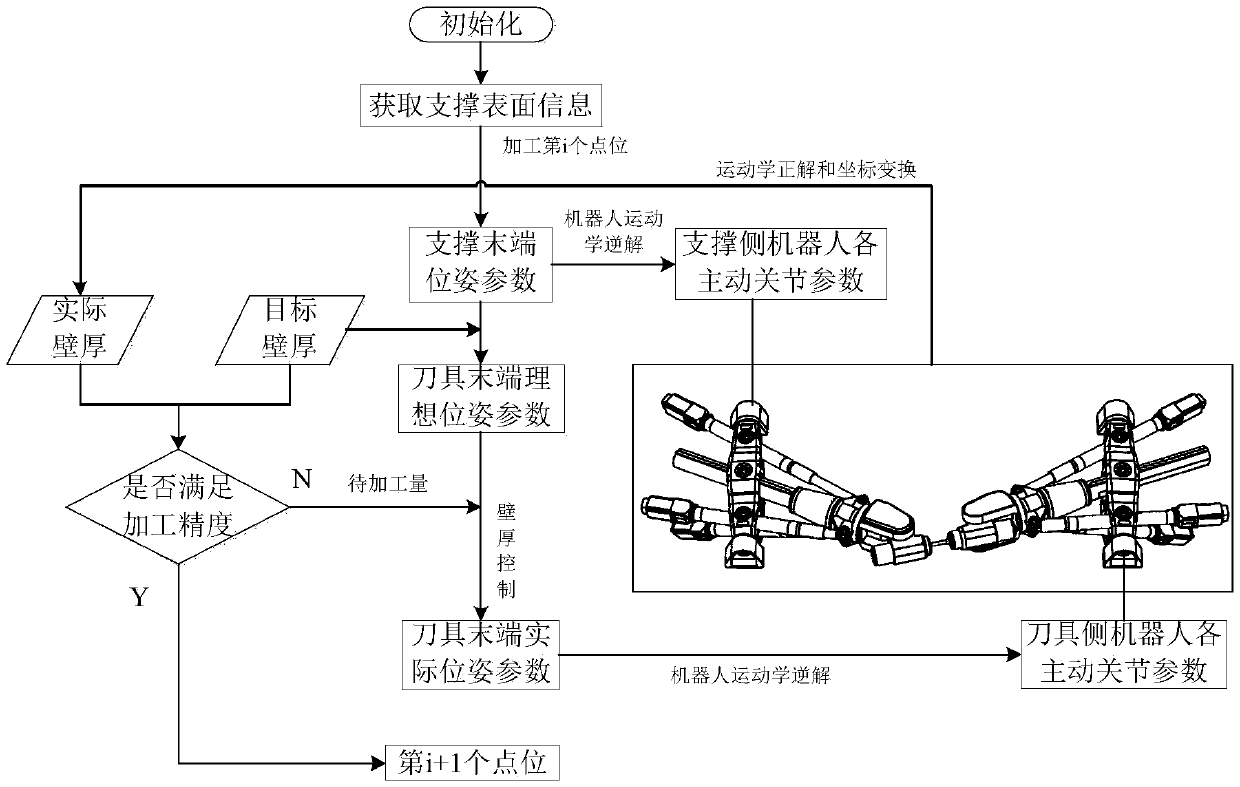

[0073] Based on a five-degree-of-freedom hybrid robot disclosed in patent CN104985596A, it is assumed that the thin-walled curved surface component is a thin-walled cylinder with a diameter of 3.2m, the original wall thickness is about 4mm, and the target wall thickness is 2mm.

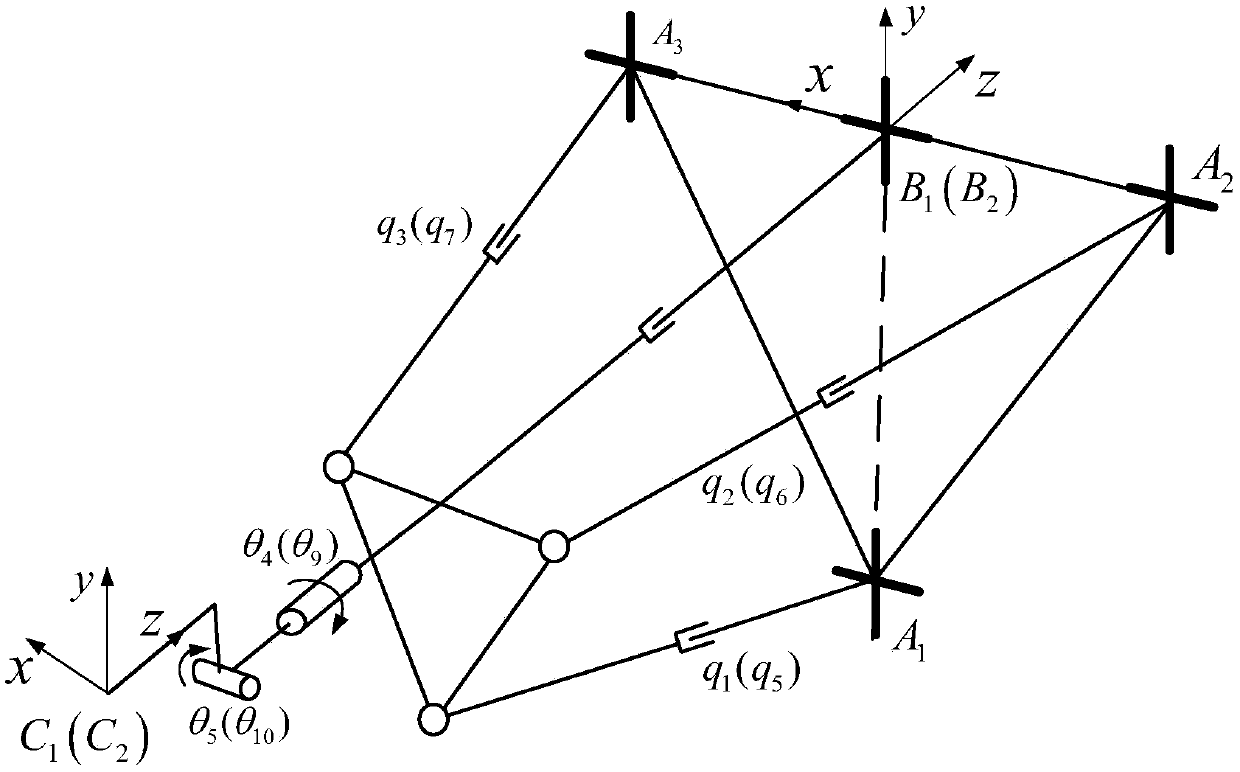

[0074] Establish the following coordinate systems and their transformation relations:

[0075] Base coordinate system B of the robot at the support end 1 -xyz, which is built on the fixed base of the support end robot;

[0076] Tool end robot base coordinate system B 2 - xyz, which is built on the tool end robot fixed base;

[0077] Tool coordinate system C at the end of the robot at the support end 1 -xyz, the origin of its coordinates coincides with the center of the end of the support head under the zero position of the robot at the support end;

[0078] Tool end robot end tool coordinate system C 2 -xyz, its coordinate origin coincides with the center of the tool end under the zero position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com