Moving and carrying device applicable to industrial robot

A technology for industrial robots and delivery devices, applied in the directions of manipulators, manufacturing tools, etc., can solve the problems of reduced work efficiency, increased use and maintenance costs of industrial robots, etc., to save time and cost, reduce use and maintenance costs, and simple principles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

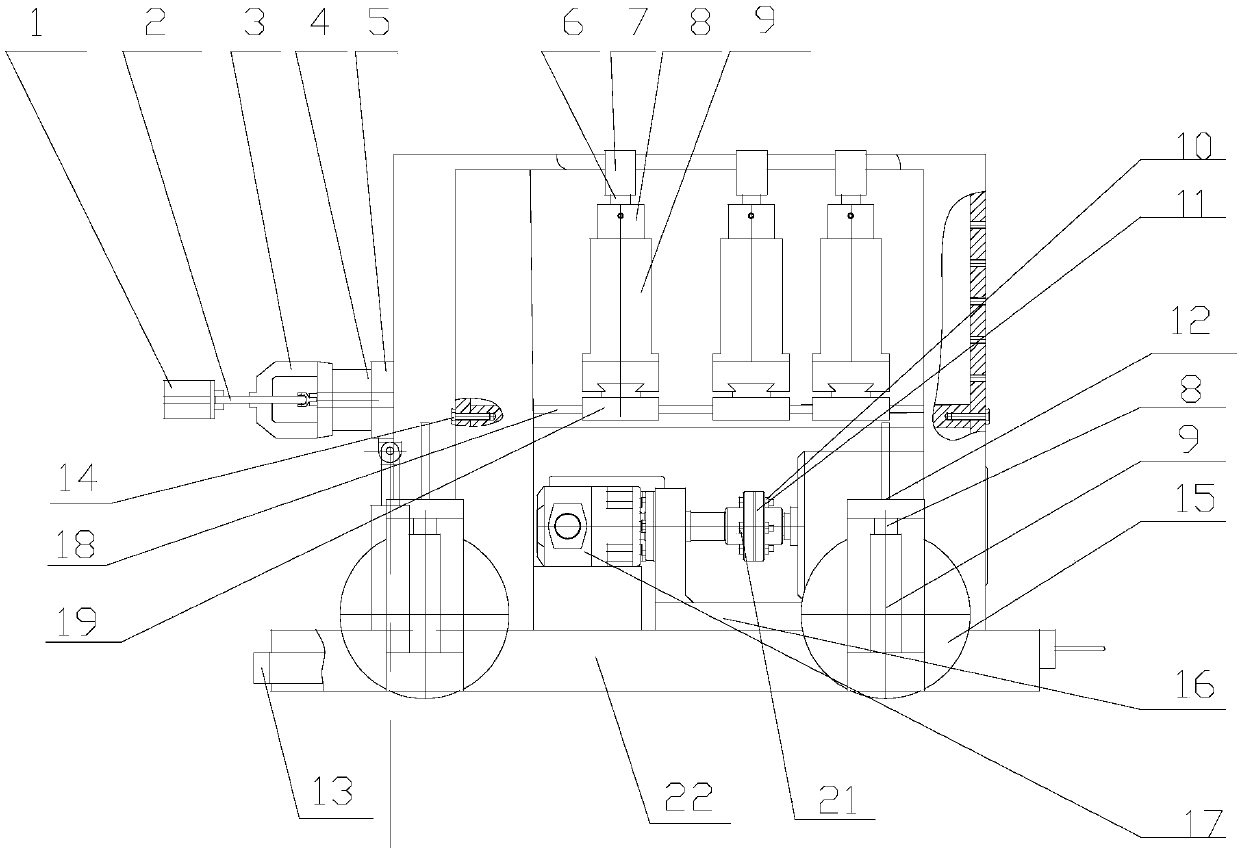

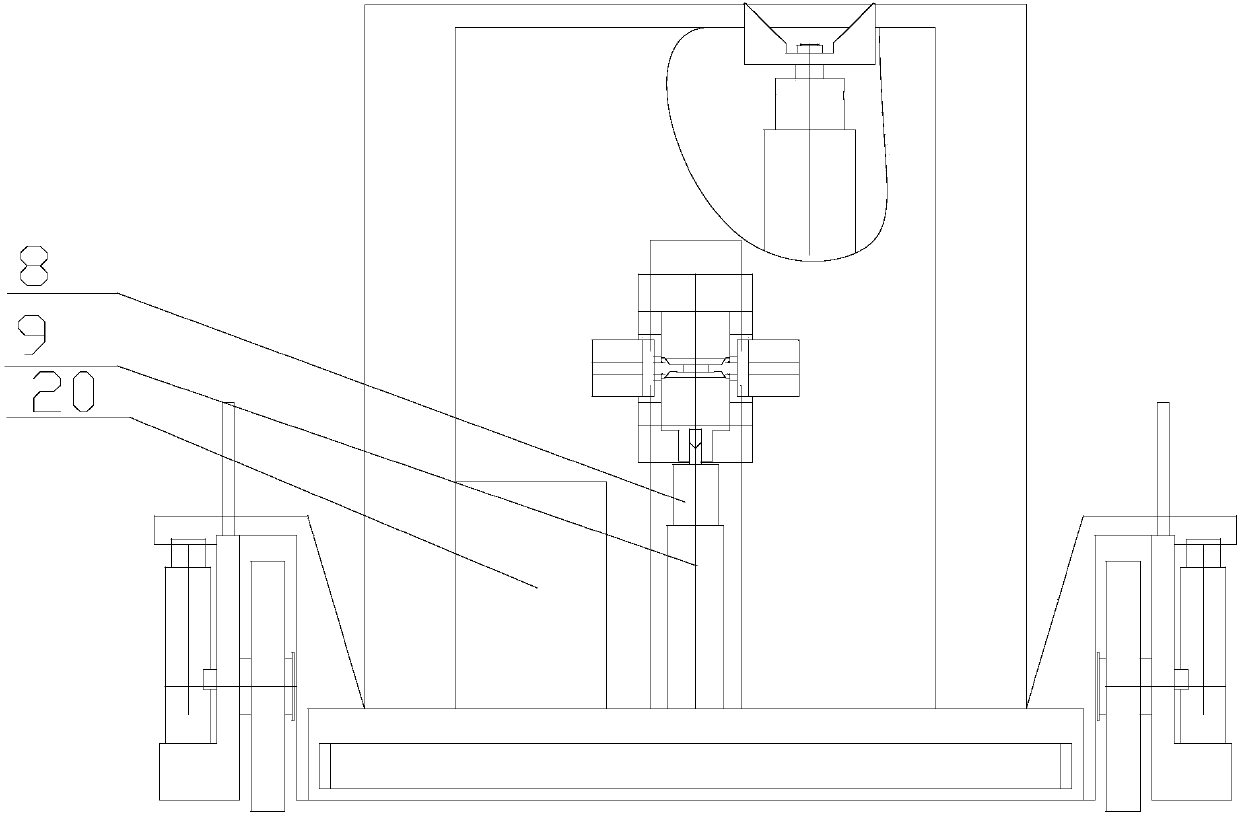

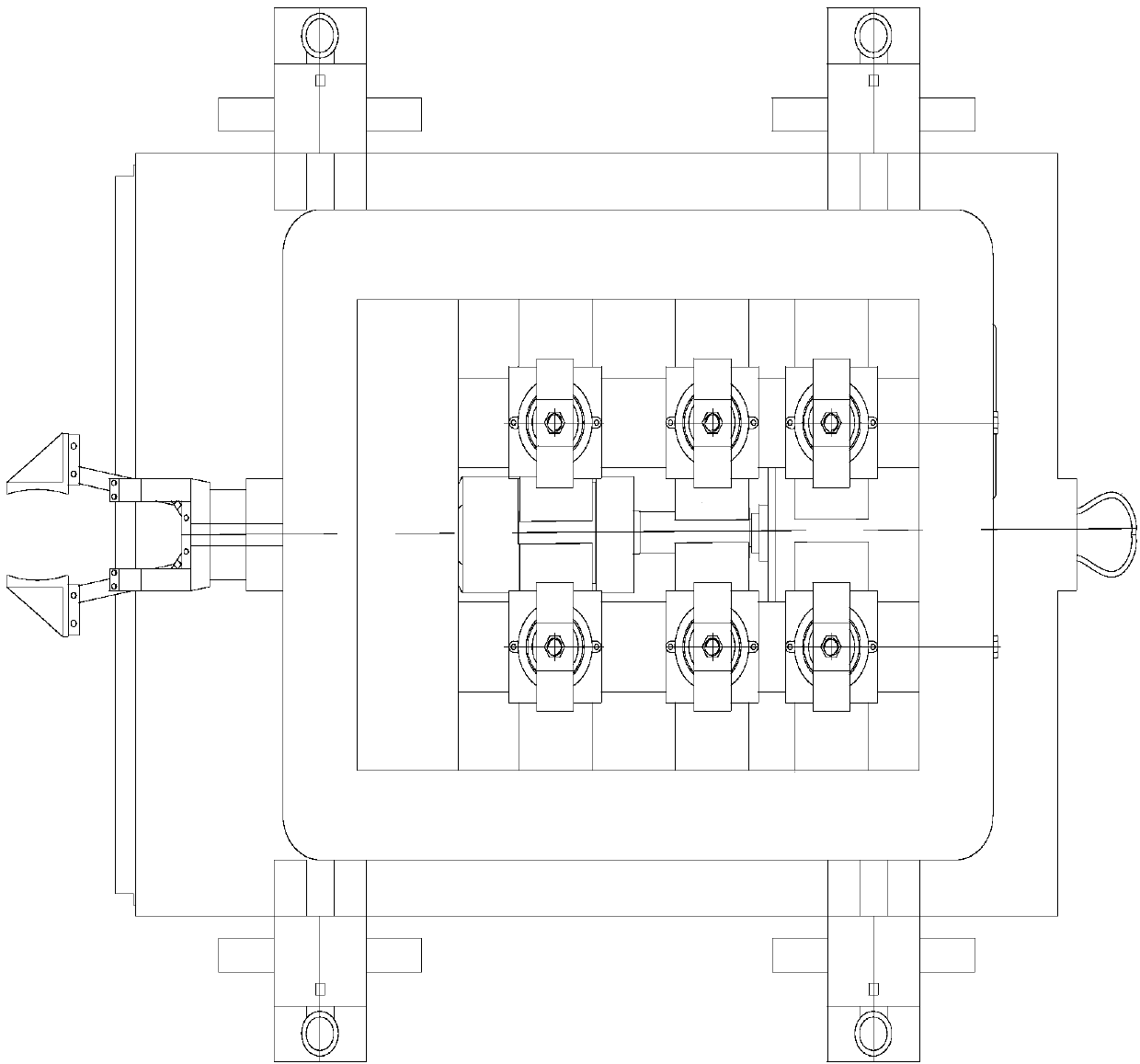

[0028] A mobile carrying device suitable for industrial robots, including a car body, a power unit, a hydraulic transmission unit, a transverse joint grasping unit, a vertical joint grasping unit, a telescopic bottom plate, and a wheel assembly. The power unit and the hydraulic transmission unit are installed on the vehicle Inside the body, the vertical joint grabbing part is installed on the front side of the car body, the transverse joint grabbing part is installed on the upper part of the car body, the telescopic bottom plate is installed on the front side of the bottom of the car body, and the power part is connected with the hydraulic transmission part. The hydraulic transmission part is connected with the horizontal joint grabbing part and the vertical joint grabbing part. The power part drives the horizontal joint grabbing part and the vertical joint gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com