Mold for producing concrete pipes

A technology for concrete pipes and molds, applied in the direction of molds, etc., can solve the problems of low investment, low production efficiency, core mold vibration and high efficiency of radial extrusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

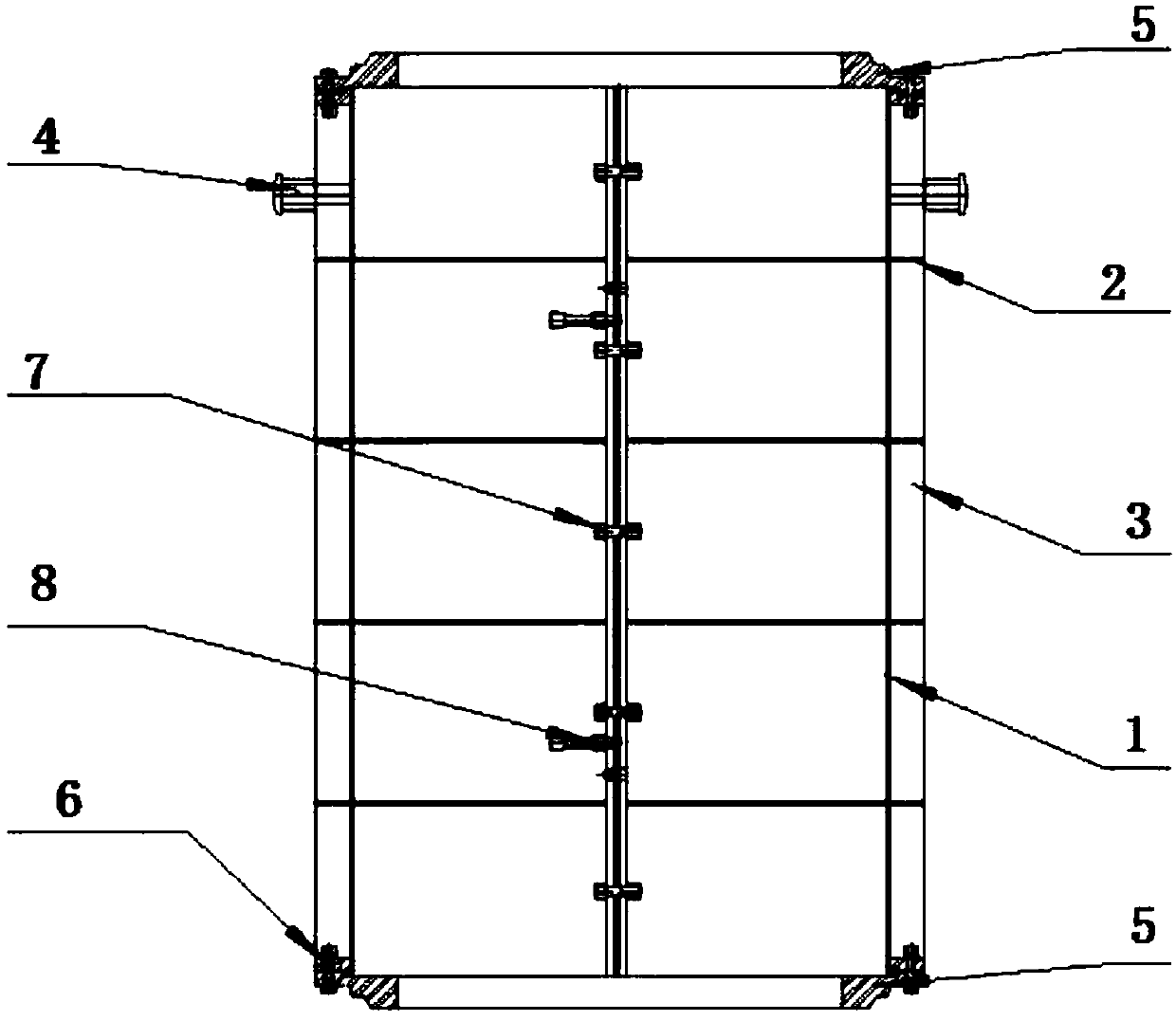

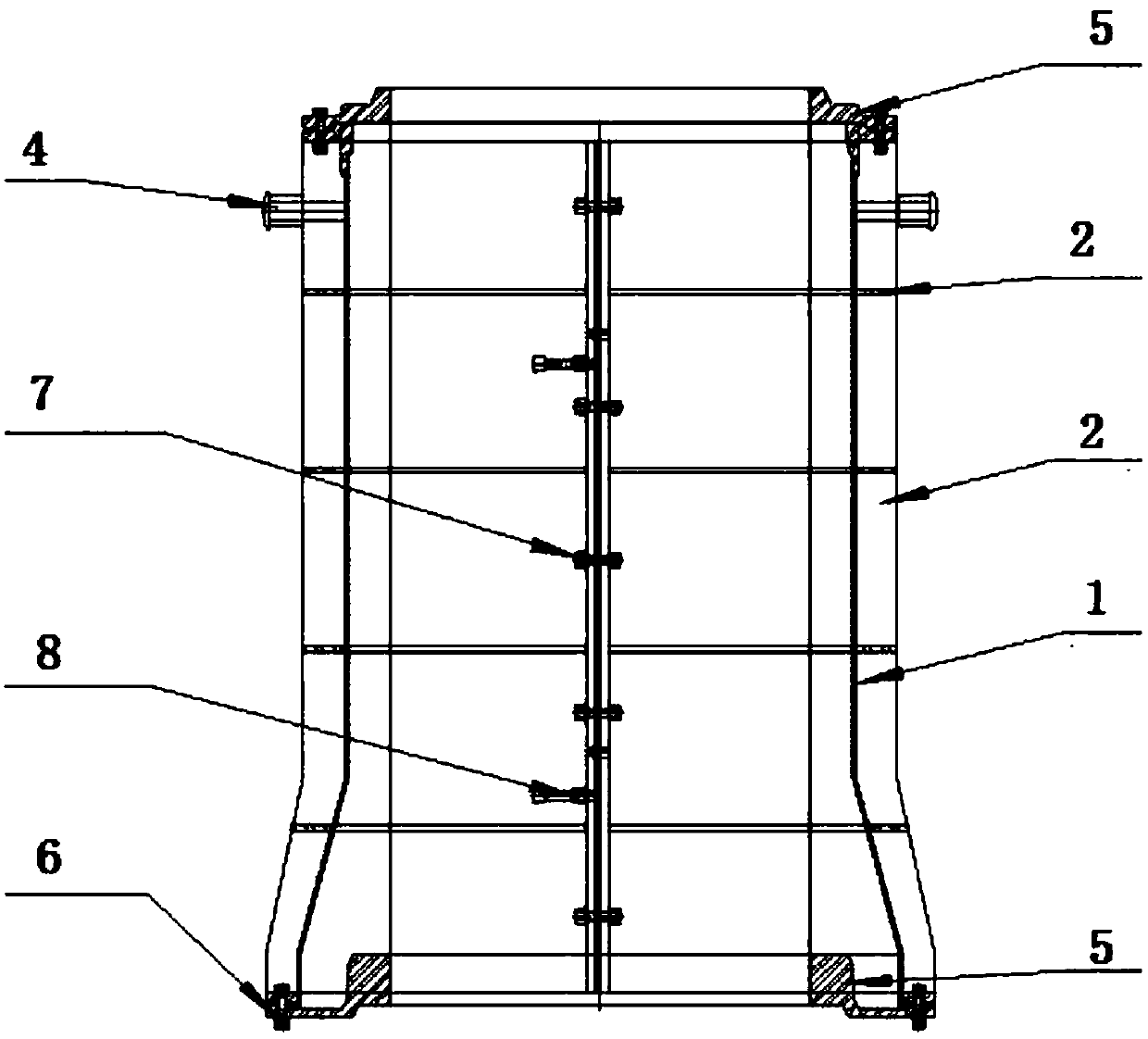

[0031] see figure 1 , figure 2 , a mold for concrete pipe production provided by the embodiment of the present invention, such as figure 1 , figure 2 As shown, the cylindrical mold main body 1 is made of steel plate rolled round and has open ends; the outer side of the cylindrical mold main body 1 is provided with a plurality of annular reinforcing ribs 2 and a plurality of transverse reinforcements Rib 3 and / or multiple longitudinal ribs; the main body of the cylindrical mold 1 is provided with a hoisting turning shaft 4; the annular rib 2 includes a vertical annular rib plate, a horizontal annular rib plate, and a round shaped profile Any one or combination of several types of ribs. The number of the annular reinforcing ribs is 2 to 20 rings. The transverse reinforcement 3 includes any one or combination of vertical ribs, horizontal ribs, and profile ribs. The longitudinal reinforcement includes any one or combination of vertical ribs, horizontal ribs, and profile rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com