Obtaining system for high uniformity work site slurry

A technology for obtaining system and uniformity, applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of weak mixing function and poor mixture uniformity, and achieve strong mixing function, good uniformity, and improved The effect of blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

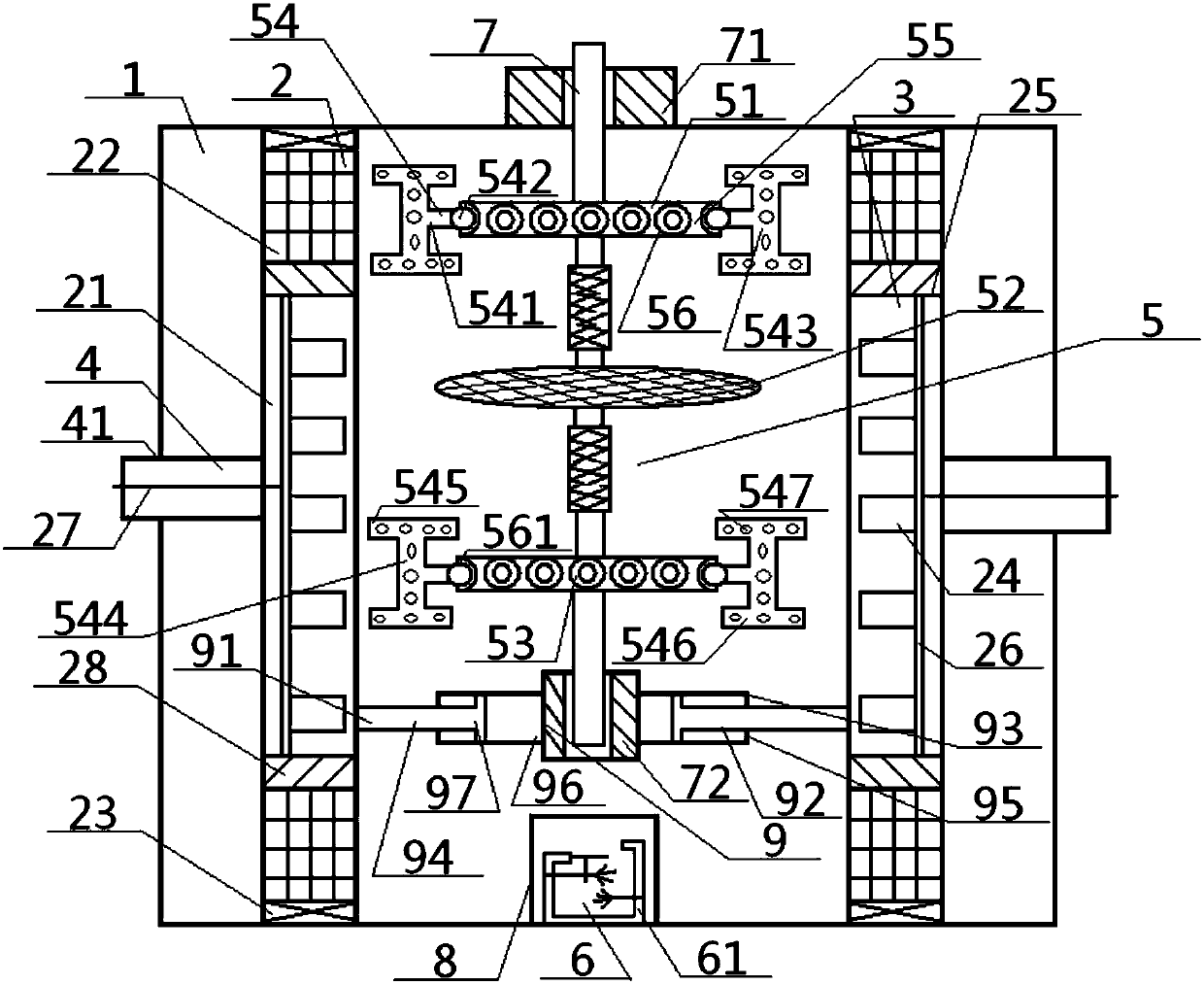

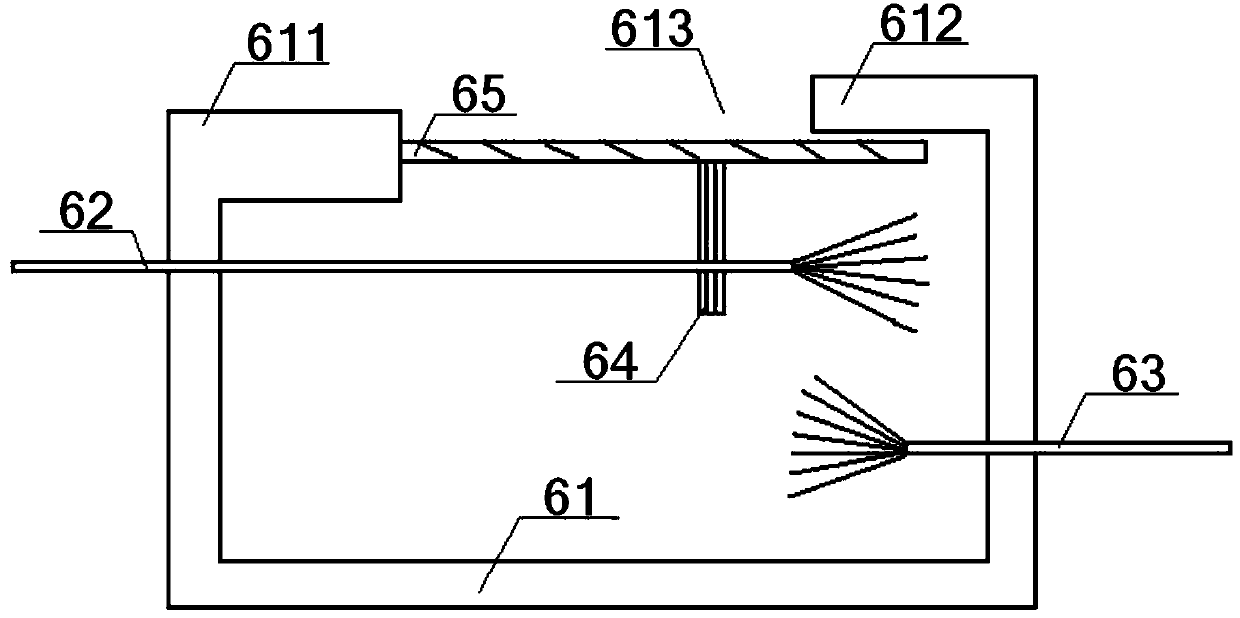

[0027] see Figure 1 to Figure 2 , a high-uniformity construction site slurry acquisition system, including a cylindrical workshop 1, a mixing device 5 and a stirring spindle 7, the interior of the cylindrical workshop 1 is provided with a mixing device 5, and the interior of the mixing device 5 is provided through There is a stirring spindle 7;

[0028] The interior of the cylindrical workshop 1 is provided with a symmetrical left heating device 2 and a right heating device 3, and the left heating device 2 and the right heating device 3 both include a heating part 21, a filter part 22 and a sliding piston. 23. The back of the heating part 21 is connected to the inner end of the push rod 4, and the outer end of the push rod 4 passes through the push rod hole 41 set on the side wall of the cylindrical workshop 1 and then extends to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com