Easy-to-assemble wear-resistant dual-side supporting wheel

A supporting wheel and bilateral technology, which is applied in the direction of transportation and packaging, tracked vehicles, motor vehicles, etc., can solve the problems that the supporting wheel affects the use and life, and achieves the effect of improving the service life and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

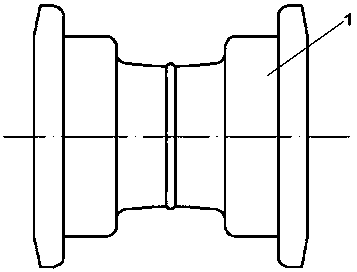

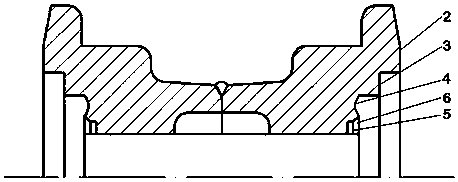

[0021] Such as figure 1 , 2 As shown, an easy-to-install wear-resistant double-sided support wheel includes a wheel body 1, and both axial ends of the wheel body 1 are floating sealing ends 2, and the floating sealing ends 2 form coaxial The shaft seat assembly hole 3 and the floating seal ring assembly hole 4, the hole bottom of the floating seal ring assembly hole 4 includes an arc-shaped bottom wall away from the axis and a straight bottom wall close to the axis. The wear-resistant sheet assembly ring groove 5 of the grinding sheet forms a guide assembly groove 6 at the opening of the wear-resistant sheet assembly ring groove 5, and the groove wall of the guide assembly groove 6 is a conical surface.

[0022] The taper of the groove wall of the guide assembly groove 6 is adapted to the taper of the tapered portion of the fixed end of the wear-resistant sheet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap