A multifunctional diaper robot packing machine

A technology of robots and diapers, which is applied in the field of multi-functional diaper robot boxing machines, can solve the problems of delayed automation upgrade speed, high production cost, and unliberated labor force, so as to improve the scope of application, perfect functions, and reduce replacement. type time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0053] A multifunctional paper diaper robot box packing machine includes suction box packing and gripping box packing.

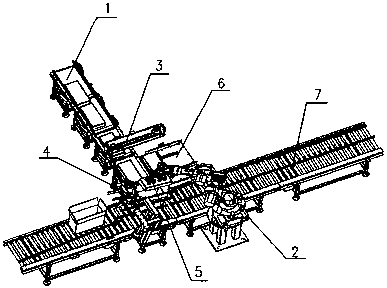

[0054] Such as figure 1 As shown, the suction packing includes four-stage feeding 1, six-axis packing robot 2, side pushing mechanism 3, case supporting mechanism 4, suction cup gripper 5, suction platform 6, roller conveyor line 7, and bags are conveyed by the front The line enters the four-stage feeding 1, the first two stages of the four-stage feeding 1 accumulate the bags, the third and fourth stages carry out single-bag conveyance, and the single-bag conveying of the bags to the side push position, the side push position is the fourth stage ;Detecting that the electric eye detects that the bag is in place and there is no bag accumulation or the accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com