Bladeless fan

A bladeless fan and air cavity technology, applied in liquid fuel engines, non-volume pumps, mechanical equipment, etc., can solve the problems of low production efficiency, air transmission loss, non-disassembly, etc., to improve the air supply effect and improve the noise problems, effects of avoiding transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

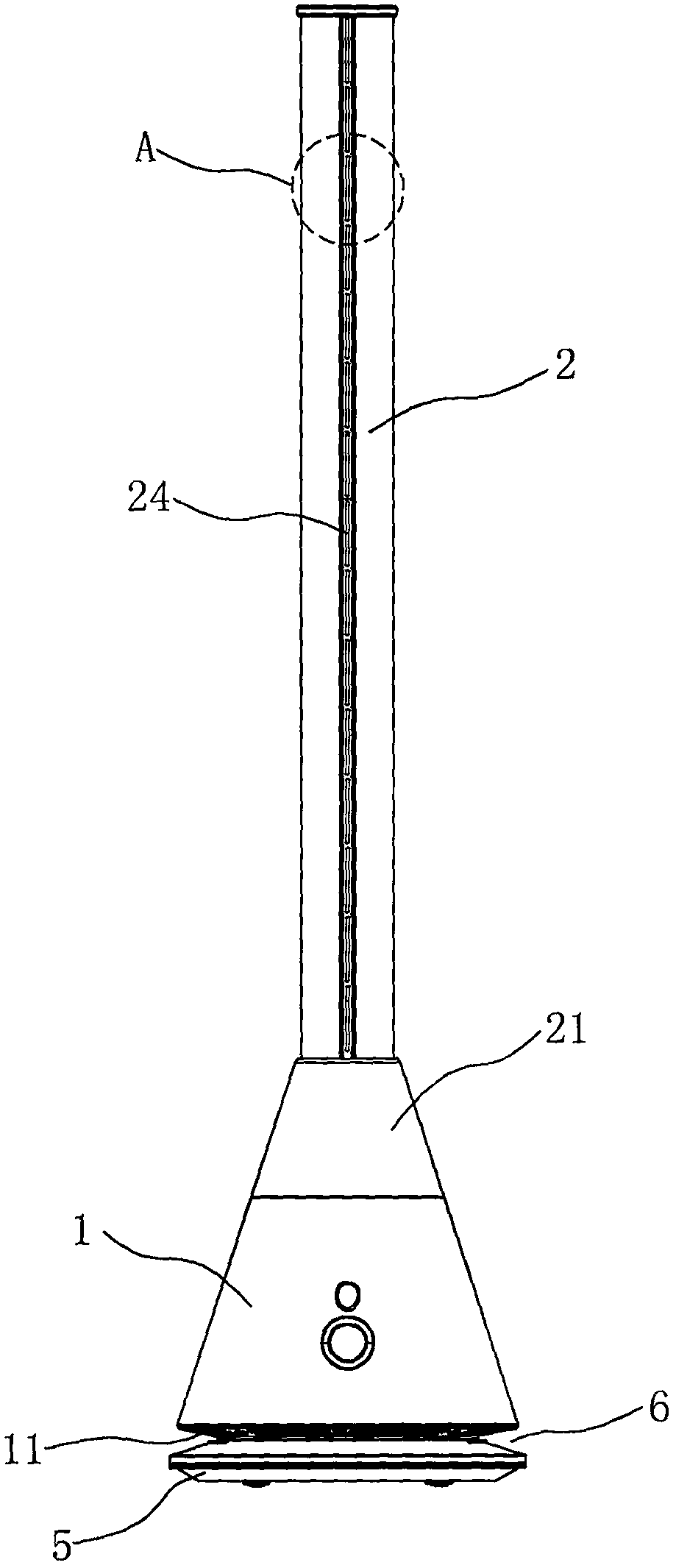

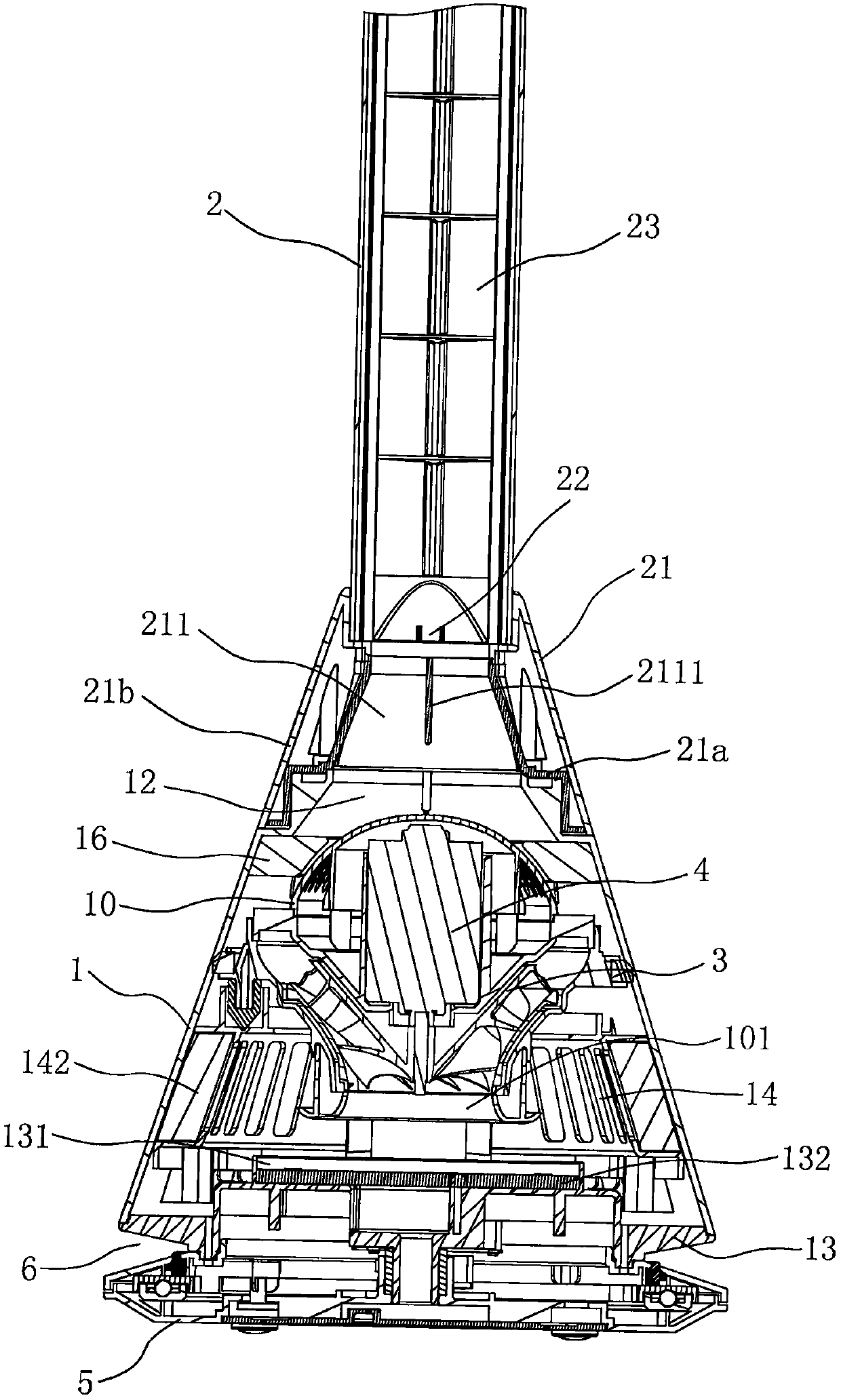

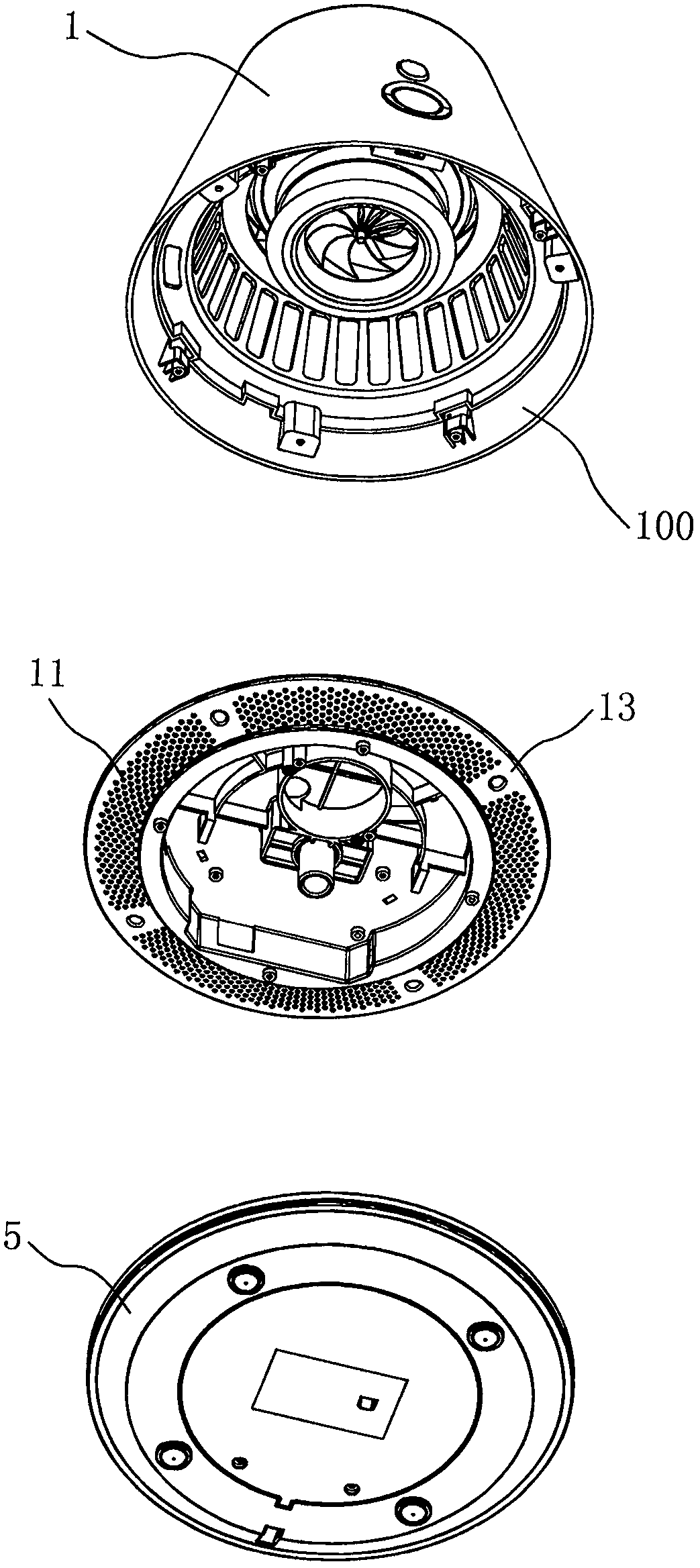

[0036] Such as Figure 1 to Figure 10 As shown, a bladeless fan of the present invention includes a base body 1 and an air outlet tube 2 arranged at the upper end of the base body 1, and the bottom of the base body 1 is provided with an air inlet 11 (as another alternative embodiment, also The air inlet 11 can be arranged on the side of the base body 1), the base body 1 is provided with an impeller 3 and a motor 4 for generating airflow, the upper end of the base body 1 is provided with a trumpet-shaped air outlet 12 with a small top and a large bottom, and the lower end of the air outlet tube 2 A connection sleeve 21 is provided, and a trumpet-shaped air inlet 211 with a small top and a large bottom is arranged in the connection sleeve 21. The large end of the trumpet-shaped air inlet 211 is connected with the small end of the trumpet-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com