Pre-test debugging device and method of horizontal impact point passive acoustic locating devices

The technology of positioning device and impact point is applied in the field of pre-test debugging device of horizontal impact point passive acoustic positioning device, which can solve the problems of reducing the hit rate and improving, and achieve the effects of convenient operation, improved positioning accuracy, and low requirements on the test site environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

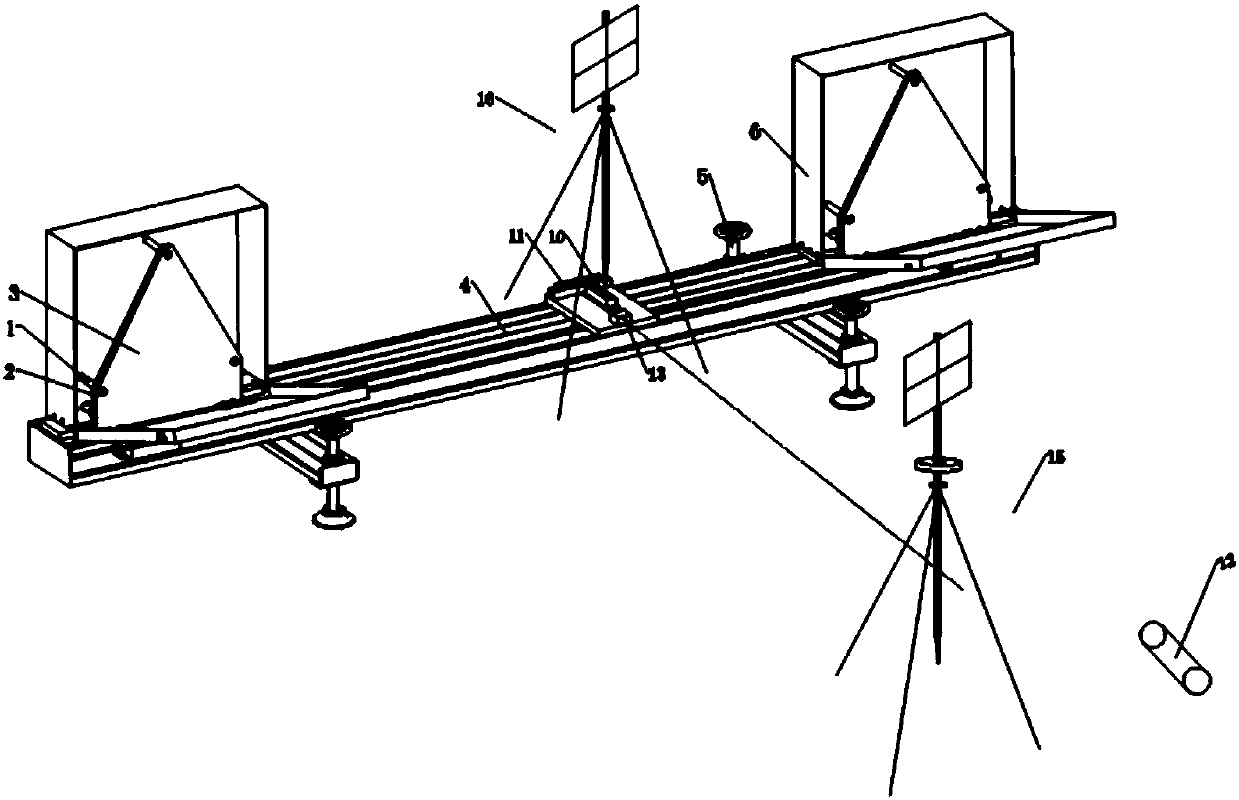

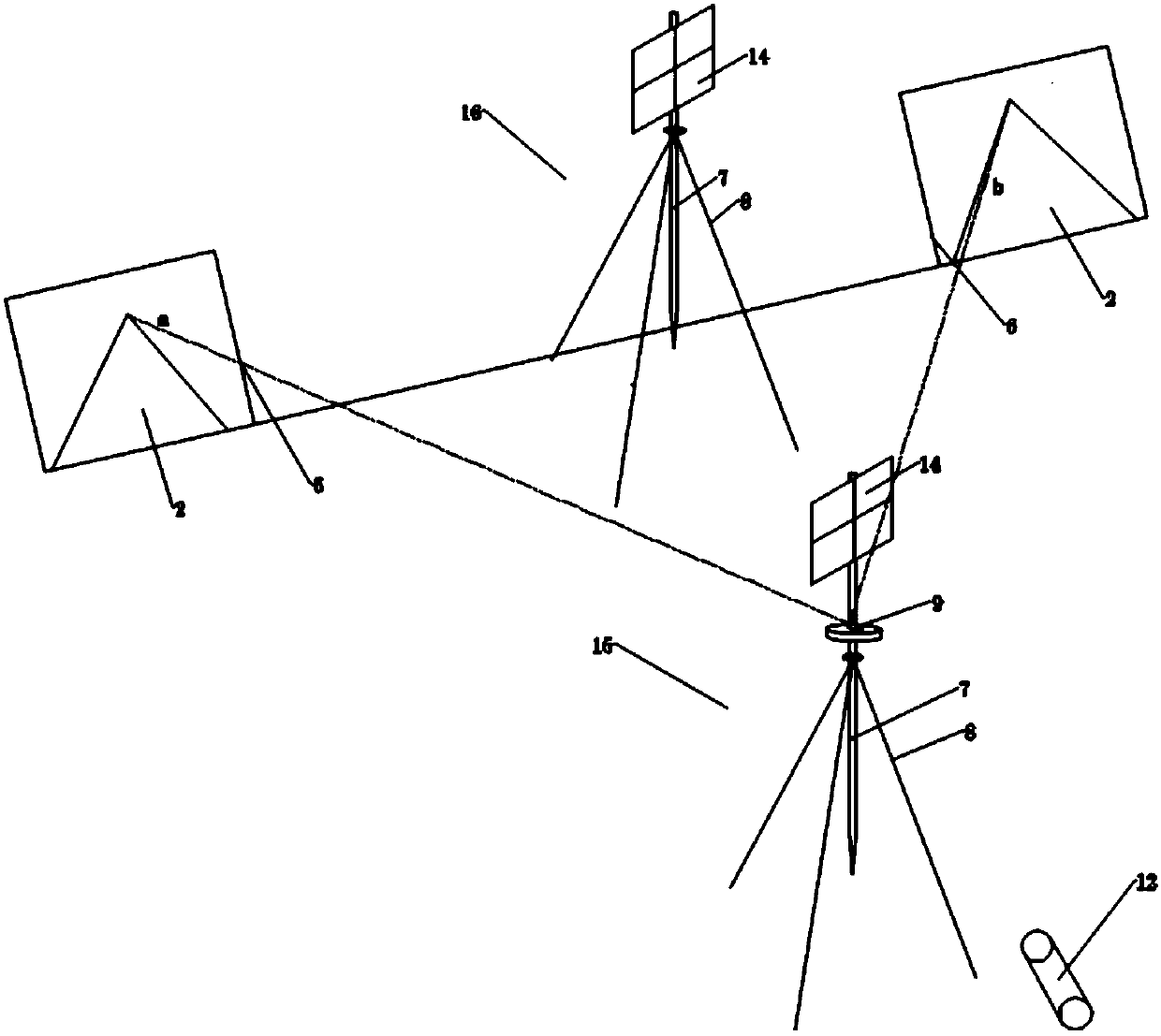

[0034] The present invention will be described in further detail below with reference to the accompanying drawings.

[0035] combine figure 1 and figure 2 , a pre-measurement debugging device for a horizontal impact point passive acoustic positioning device, including a horizontal level 11, a vertical level 10, a cross laser 13, a laser rangefinder 9, a first debugging mechanism 15 and a second debugging mechanism 16. The horizontal impact point passive acoustic positioning device (MSI 541-475AS / A) includes sensor 1, sensor target surface 2, sound-absorbing material 3, beam 4, foot assembly 5 and protective cover 6, and a pair of can be symmetrically arranged at the bottom of beam 4. Adjust the foot assembly 5 to adjust the height of the beam 4 . The two sensor target surfaces 2 are symmetrically fixed on both ends of the beam 4 , and the target surfaces are perpendicular to the center line of the beam 4 in the longitudinal direction.

[0036] The longitudinal level 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com