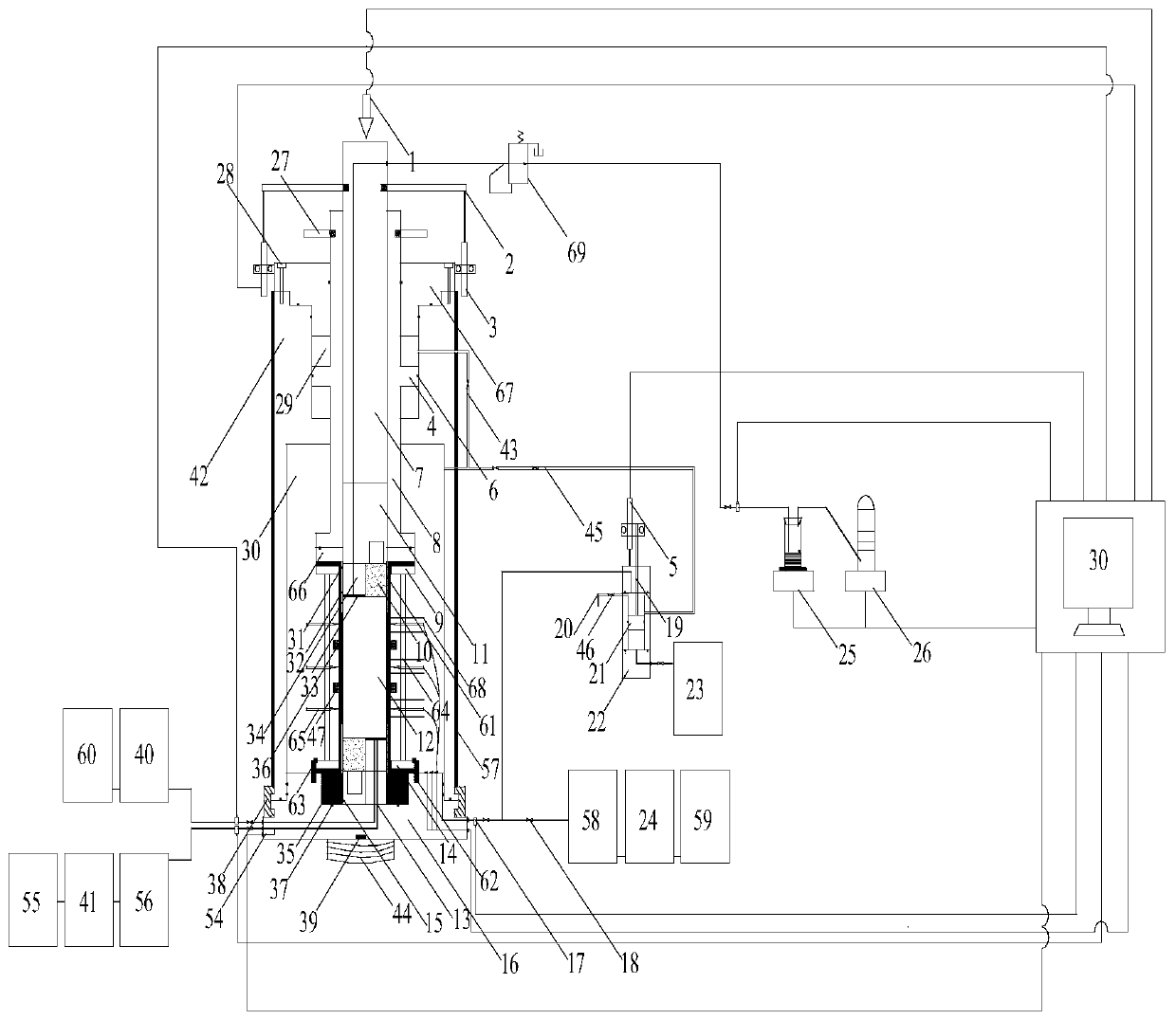

Microcomputer-controlled electro-hydraulic servo rock triaxial dynamic shear seepage coupling test device

An electro-hydraulic servo, microcomputer-controlled technology, applied in the direction of using stable shear force to test material strength, measuring device, and using stable tension/pressure test material strength, etc., can solve unscientific and inaccurate, test functions The problems of single, inconsistent occurrence of rock mass stress state, etc., achieve the effect of good lateral sealing effect, simple disassembly of the instrument, and simple control steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

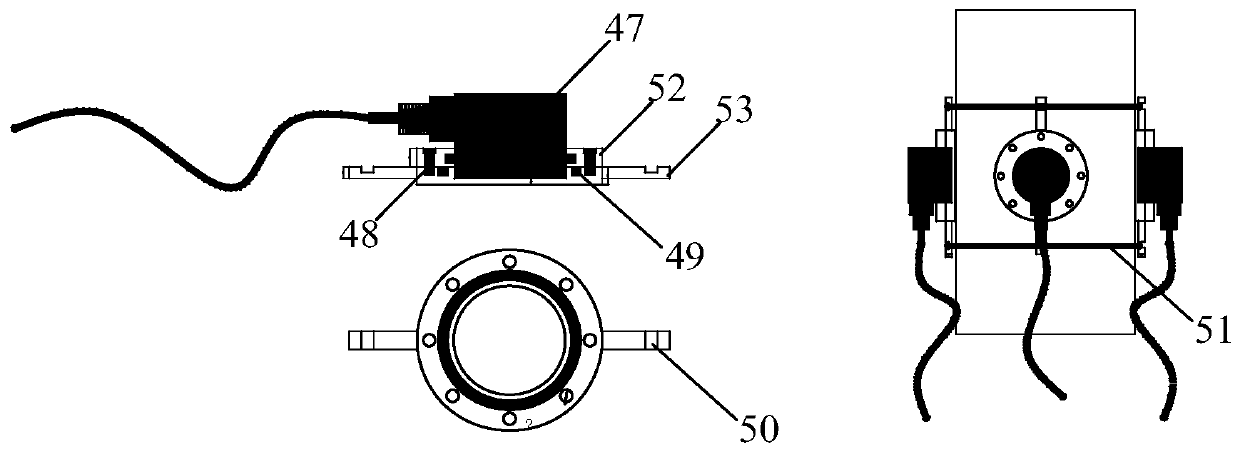

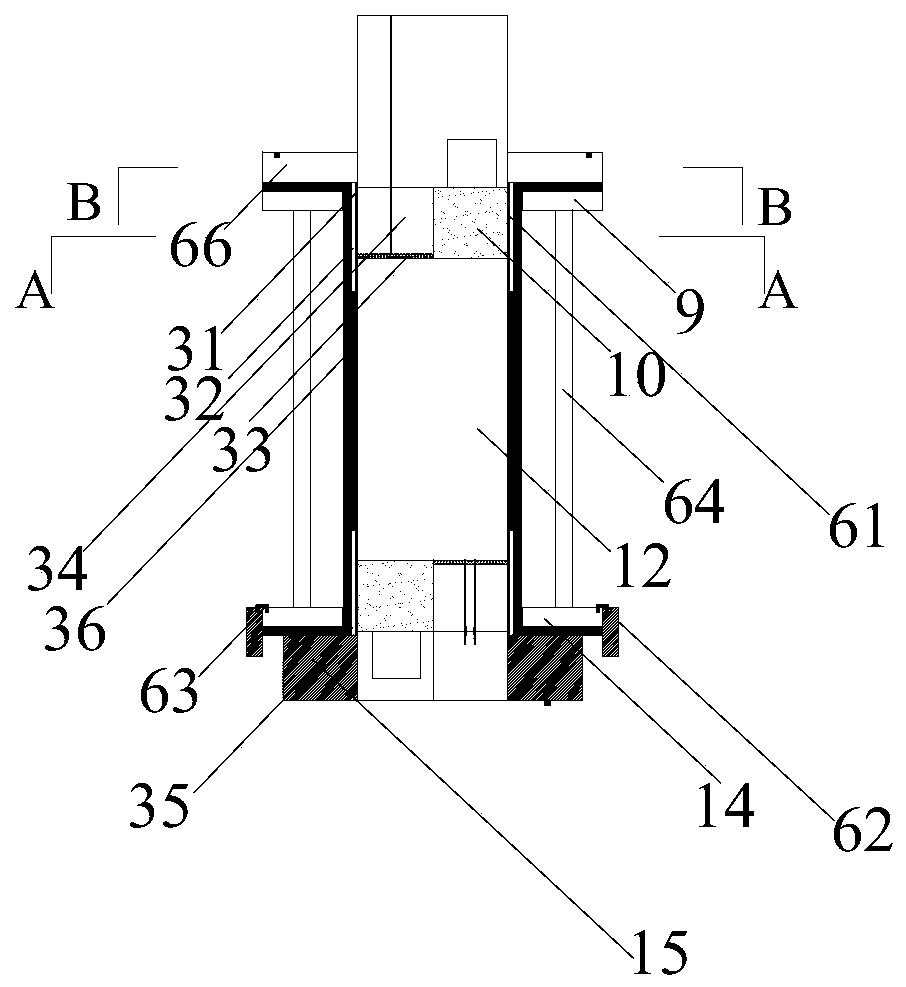

[0020] In order to reflect the technical solutions and advantages of the present invention, the implementation of a microcomputer-controlled electro-hydraulic servo rock triaxial dynamic shear-seepage coupling test method is discussed in detail below through examples and with reference to the accompanying drawings. Here, a cylindrical complete rock fine sandstone specimen with a size of φ50×100mm is taken as an example, and pure water is selected as the seepage medium, and then this device is used to compare and study the dynamic shear-seepage coupling characteristics of the fine sandstone specimen and conventional shear Differences in seepage characteristics.

[0021] Firstly, the experimental research on the coupling characteristics of dynamic shear-seepage is carried out, and the specific implementation steps are as follows:

[0022] Step 1, Sampling: Drill a cylindrical large-sized complete fine sandstone rock with a size of φ50×100mm on the large original rock, and polish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com