TFT assembly of curved liquid crystal display panel

A technology for liquid crystal display panels and components, applied in transistors, electrical components, semiconductor devices, etc., can solve problems such as dislocation and poor display of upper and lower substrates, and achieve the effect of improving optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

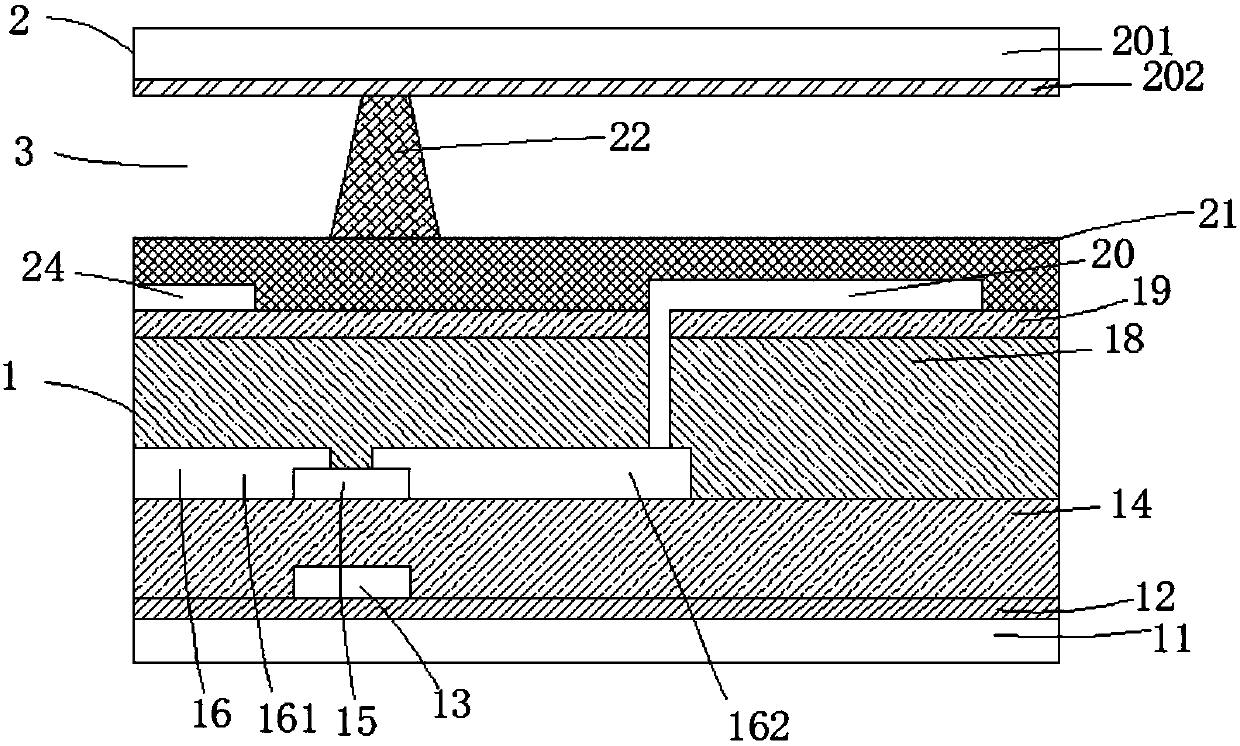

[0029] see figure 1 , the present invention provides a curved liquid crystal display panel, comprising: a first substrate 1 and a second substrate 2 arranged oppositely, and a liquid crystal layer 3 arranged between the first substrate 1 and the second substrate 2;

[0030] The first substrate 1 includes: a first base substrate 11, a plurality of scanning lines (not shown) formed on a side of the first base substrate 11 facing the second substrate 2, and a plurality of scanning lines perpendicular to the scanning lines. A data line 16, and a plurality of TFTs, covering the scanning line, the data line 16, and the insulating layer 18 of the TFT, the color resistance layer 19 disposed on the insulating layer 18, the color resistance layer 19 disposed on the color resistance layer 19 The pixel electrode 20 and the light-shielding electrode 24, the organic flat layer 21 covering the color resist layer 19, the pixel electrode 20, the light-shielding electrode 24, and the main gap s...

Embodiment 2

[0038] A method for processing a TFT component of a curved liquid crystal display panel, the steps are as follows:

[0039] 1), structure and separate processing

[0040] TFT components, including a gate on the buffer layer, a gate insulating layer covering the gate and the buffer layer, an active layer on the gate insulating layer, and an active layer on the gate insulating layer respectively The source and drain of both ends of the contact;

[0041] Each component is first prepared, assembled and compounded according to the existing technology;

[0042] 2), pre-processing

[0043] After compounding, spray the pretreatment liquid on the outer surface, and dry it with a vacuum dryer at the drying temperature of 35°C after spraying;

[0044] The components of the pretreatment liquid are: 3.5 parts of phthalates, 2.3 parts of anti-precipitation agent, 3.5 parts of leveling agent, 17 parts of glacial acetic acid, 25 parts of polystyrene resin, 2.5 parts of isatin base;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com