A Reliability Analysis Method of Mechanical Structure Based on Multi-Fault Mechanism Coupling

An analysis method and technology of failure mechanism, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., to achieve the effect of feasible method and strong practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

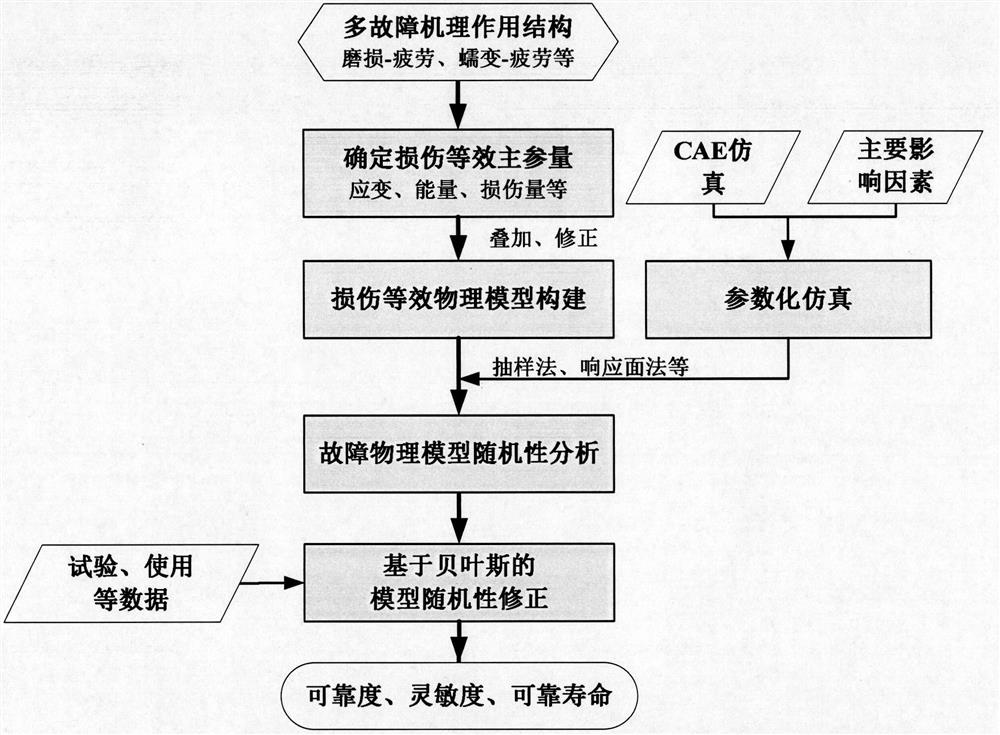

[0015] The flow chart of the present invention is as figure 1 shown, including the following steps:

[0016] 1. Determine the damage equivalent main parameter

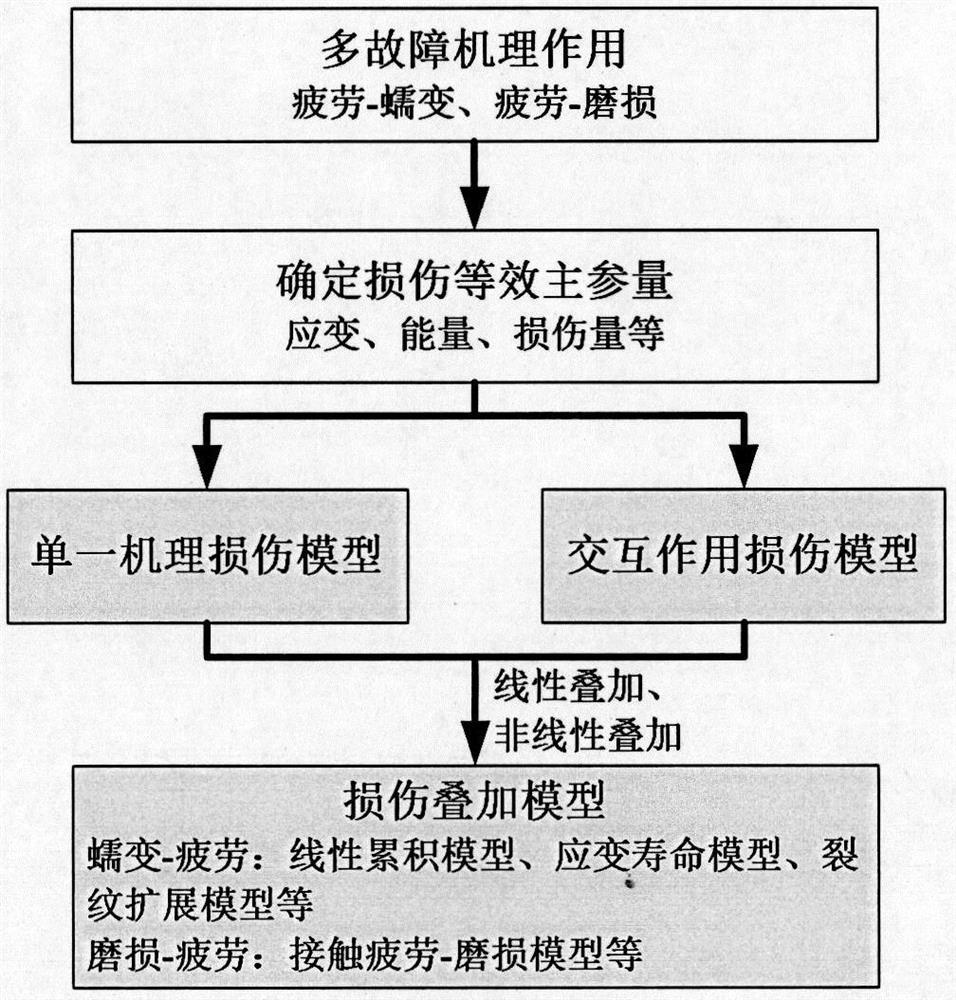

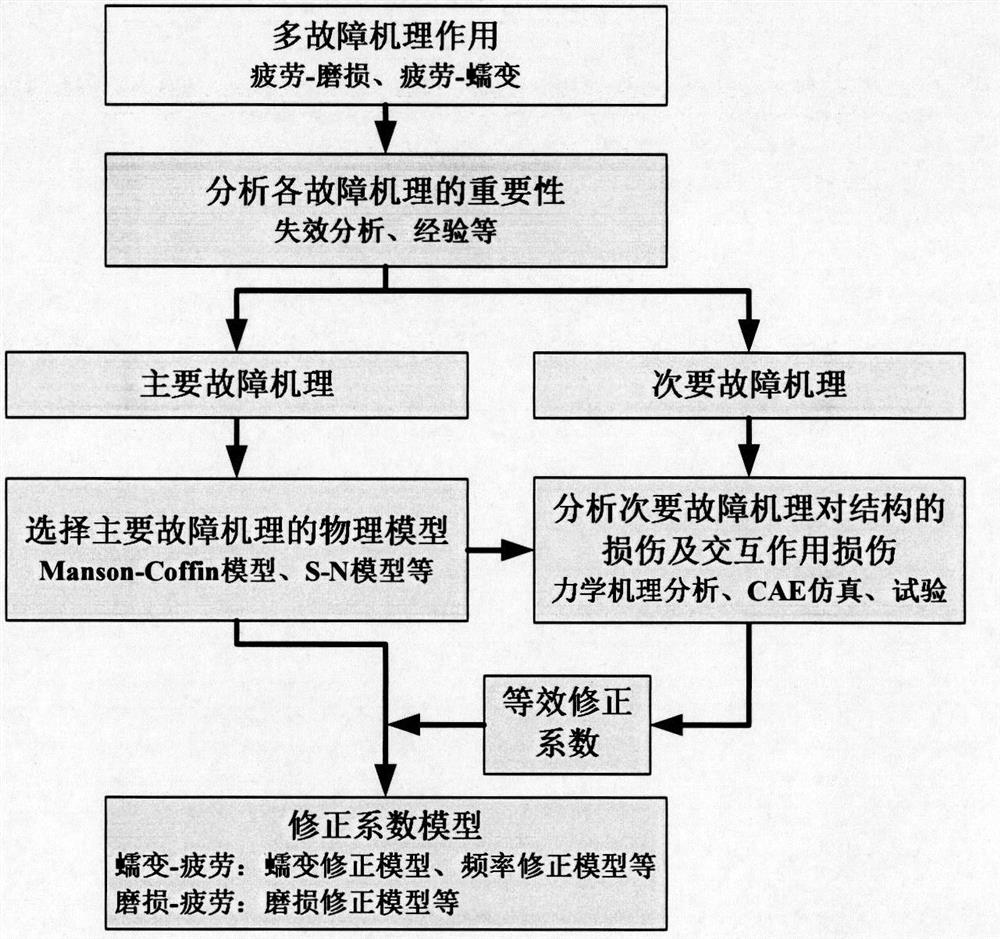

[0017] In engineering, there are many failure mechanism models such as mechanical structure fatigue, creep, and wear. For example, the main parameters of the damage model of the fatigue failure mechanism include damage amount, strain, and strain energy, etc., and the main parameters of the damage model of the creep failure mechanism include damage amount, Strain, strain rate, strain energy, etc. The main parameters of the damage model of the wear failure mechanism include wear amount, wear rate, and damage amount. Therefore, when judging all the failure mechanisms of the structure, the corresponding failure physical model is selected with the help of experience or experiments. When selecting a model, it should be considered that the main parameters of the two failure mechanisms are consistent, which will help subsequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com