A battery core spacing mechanism and a device for feeding battery cores into casings

A cell and distance separation technology, which is applied in the direction of battery assembly, non-aqueous electrolyte storage battery, and electrolyte storage battery manufacturing, can solve problems such as increased instability factors, uncontrollable free state, and hidden dangers in stability, and achieves battery cell The effect of increased quantity, strong compatibility, and stable and controllable actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

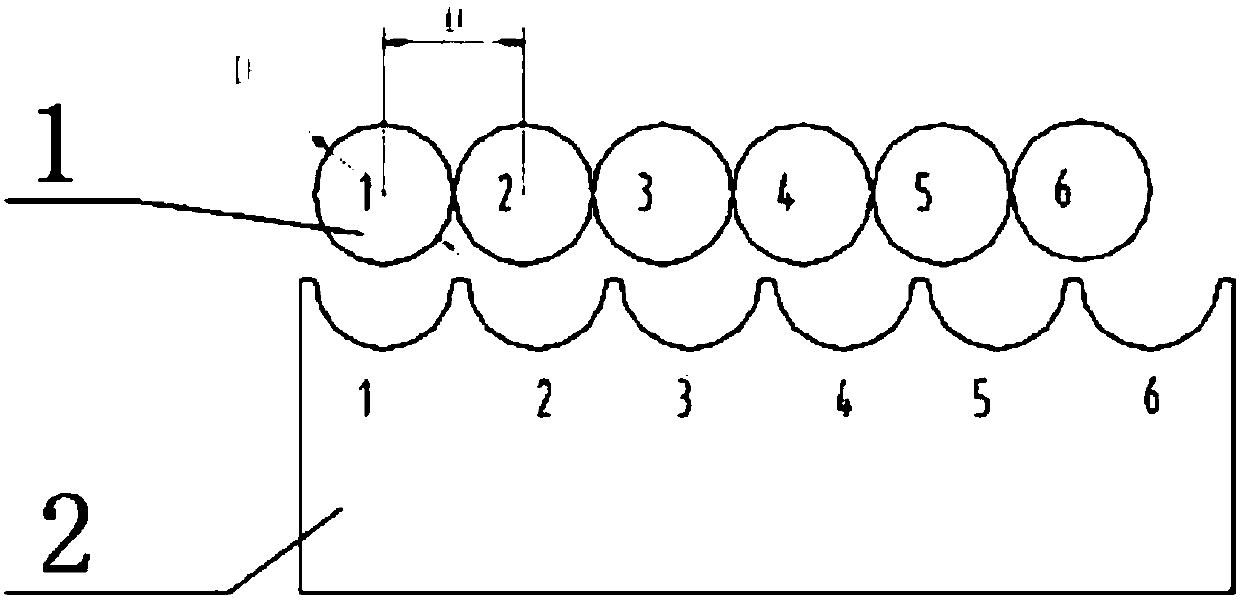

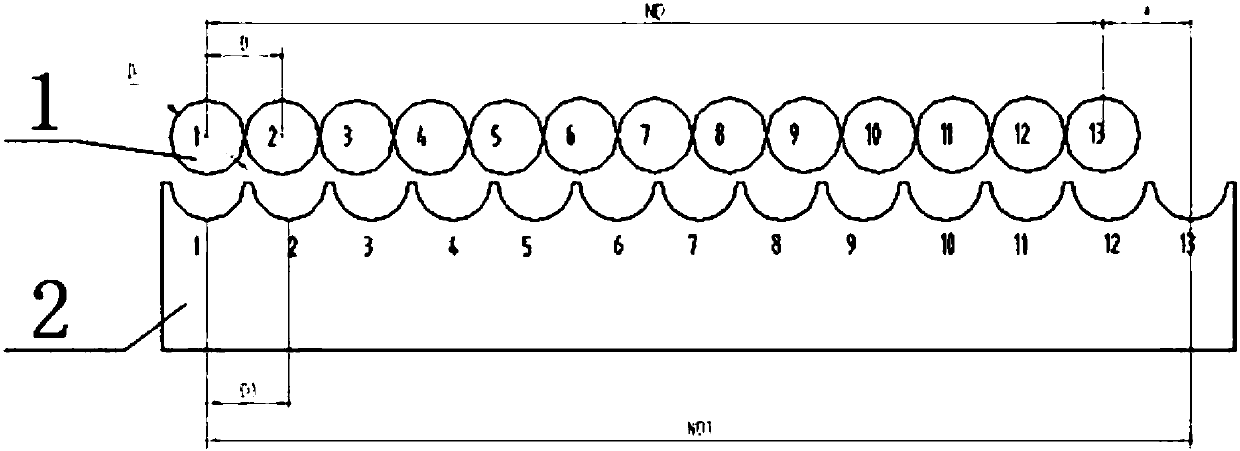

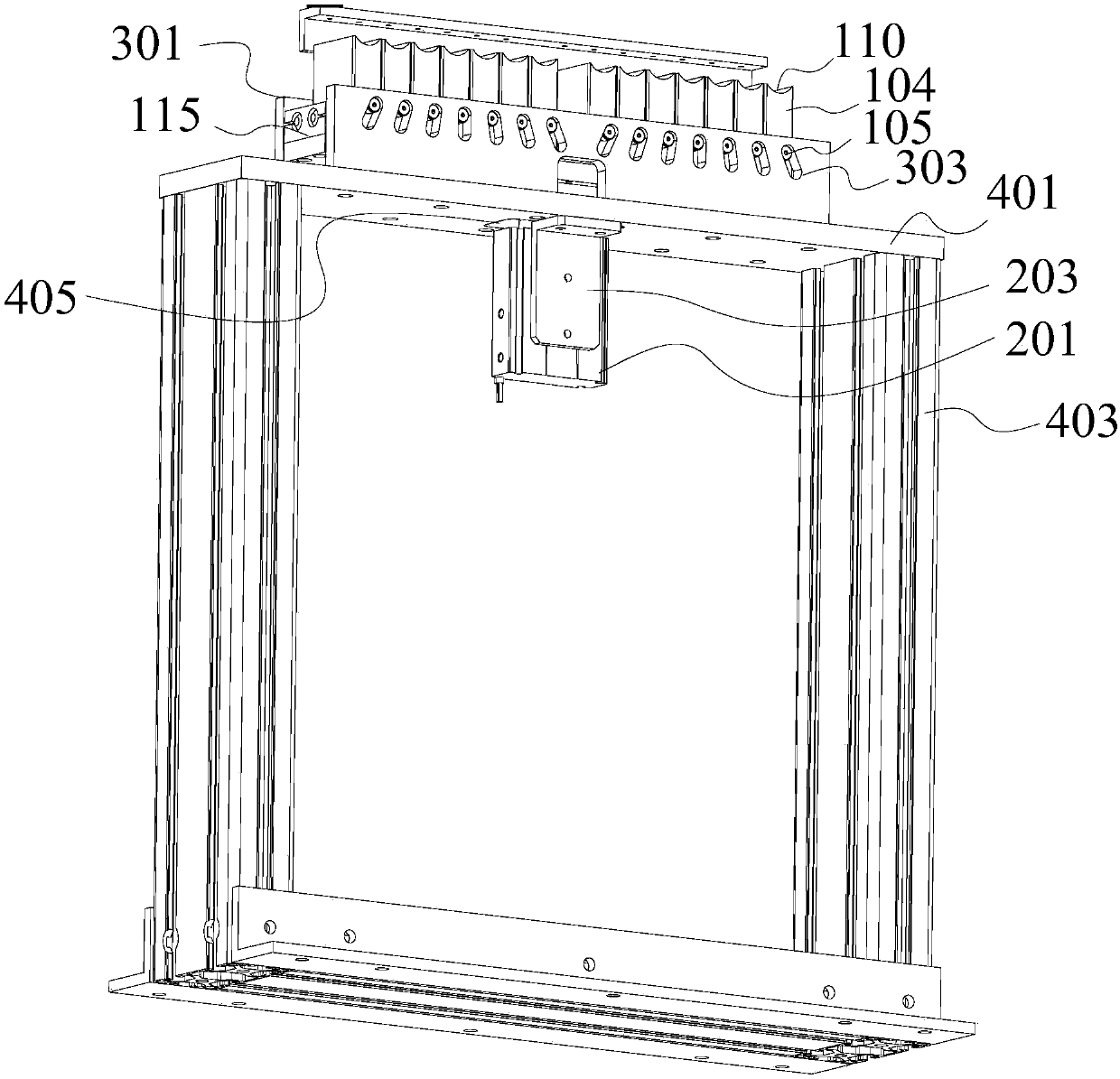

[0041] see Figure 3 to Figure 5 As shown, the present invention provides a cell separation mechanism, comprising: a cell loading assembly, a separation driving assembly and a guide assembly.

[0042] The battery cell loading assembly includes a linear guide rail 101 and a plurality of linearly arranged battery cell loading members 104 that are slidably connected to the linear guide rail 101 and are suitable for loading cells; A cam follower 105 is provided. In this embodiment, the linear guide 101 adopts, for example, but not limited to, a linear optical axis, and the corresponding cell loading member 104 is connected with the linear optical axis through the linear bearing 102 , that is, the cell loading member 104 is provided with a mounting suitable for the linear bearing 102 . Mounting holes.

[0043] The distance-separated drive assembly includes a driver 201 disposed at the middle position of the bottom of the linear guide rail 101 and adapted to drive the linear guide...

Embodiment 2

[0053] Based on the cell separation mechanism of Embodiment 1, this embodiment provides a battery cell insertion device, including the cell separation mechanism of Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap