Plastic mold edge material cutting method beneficial to mold cleaning

A technology of plastic molds and cutting methods, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as complicated procedures, inconvenient use of molds, inability to wash molds, etc., and achieve stable cutting levels , avoid misalignment, excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

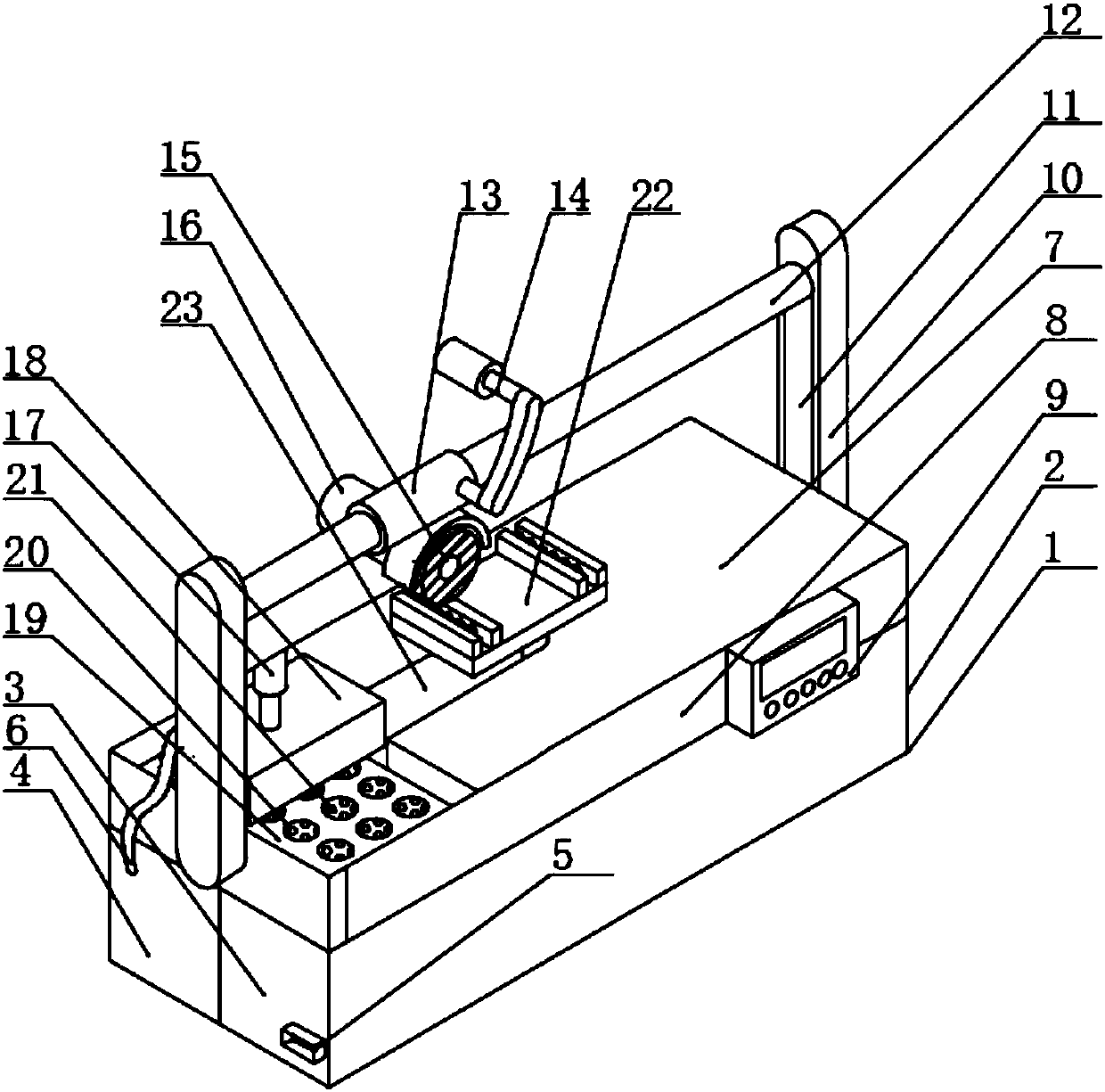

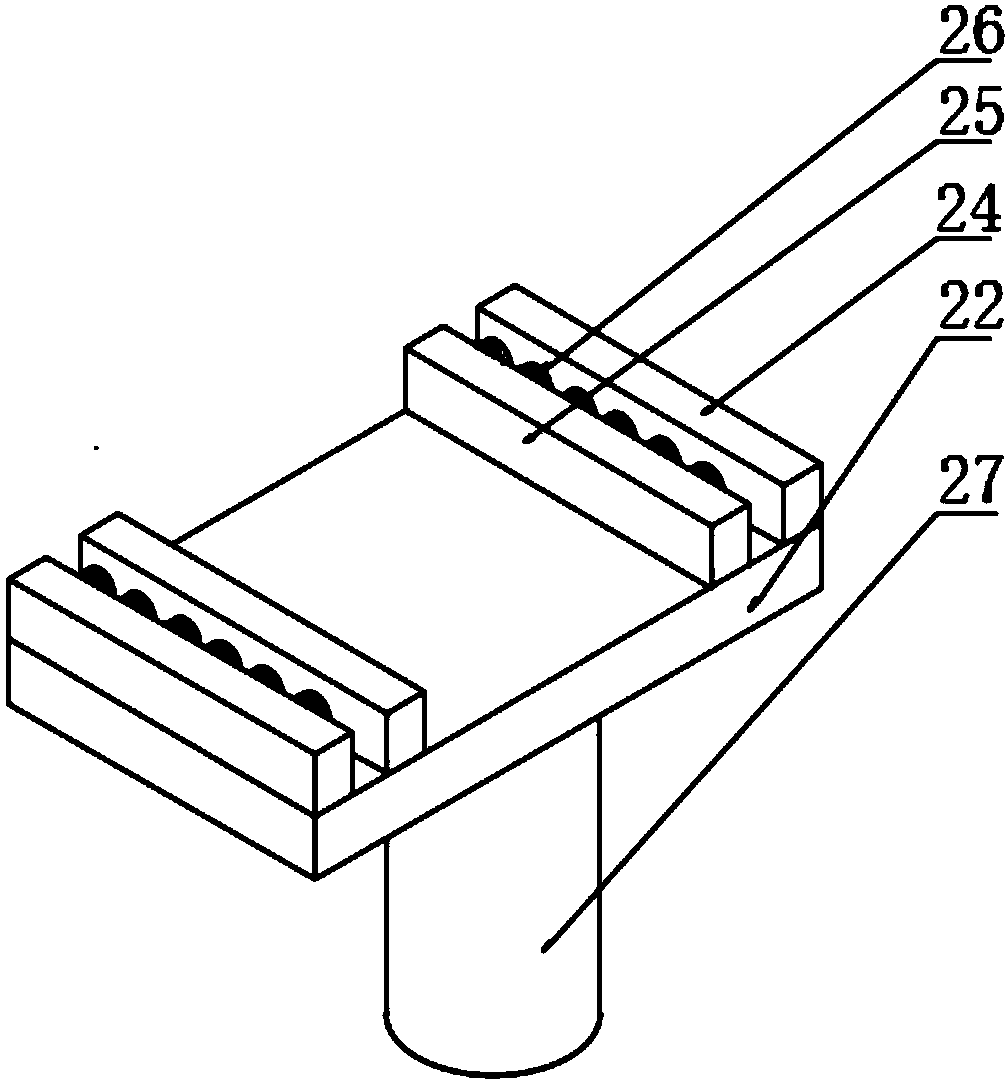

[0028] A method for cutting plastic mold offcuts that is beneficial to mold cleaning, comprising a device body 1, the surface of the device body 1 is provided with a base 2, the base 2 includes a battery box 3 and a water tank 4, and the bottom side of the surface of the battery box 5 is provided with a charging Port 5, the surface of the water tank 4 is provided with a connecting pipe 6, the connecting pipe 6 is a corrugated pipe, the top of the base 2 is provided with a working platform 7, and the surroundings of the working platform 7 are provided with a fixed plate 8, and the surface of the fixed plate 8 is provided with a control panel. Both sides of the panel 9 and the working platform 7 are symmetrically provided with support columns 10, the inner side of the support columns 10 is provided with a height adjustment chute 11, and the inside of the height adjustment chute 11 is provided with a horizontal connecting column 12, and the connecting column 12 and the height Adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com