Hoisting transportation protection assembly and production method thereof

A production method and technology of protective parts, applied in the field of hoisting and transportation protective components, can solve the problems of damaged transport parts, long custom-made cycle, non-recyclable, etc., and achieve the effects of reducing use costs, superior anti-collision and impact resistance performance, and reducing waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

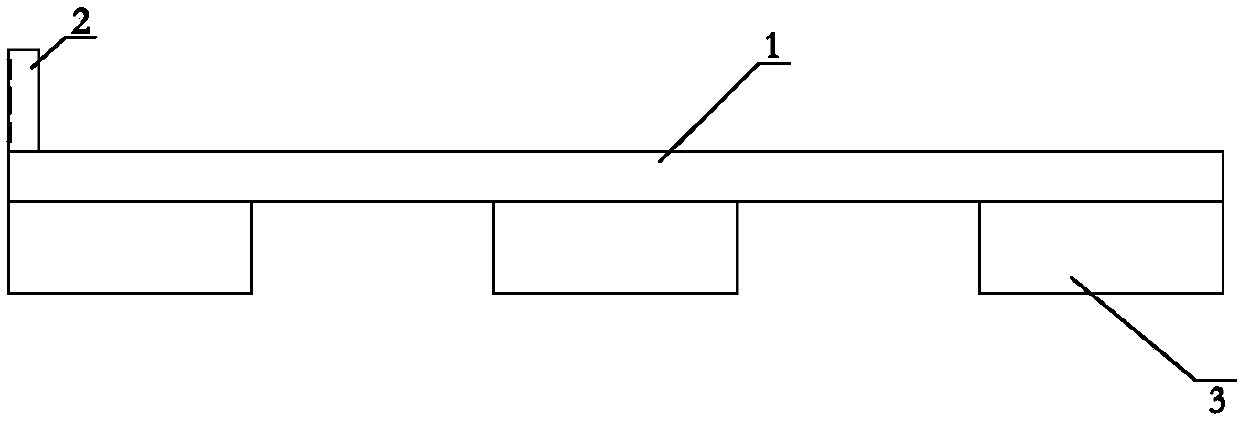

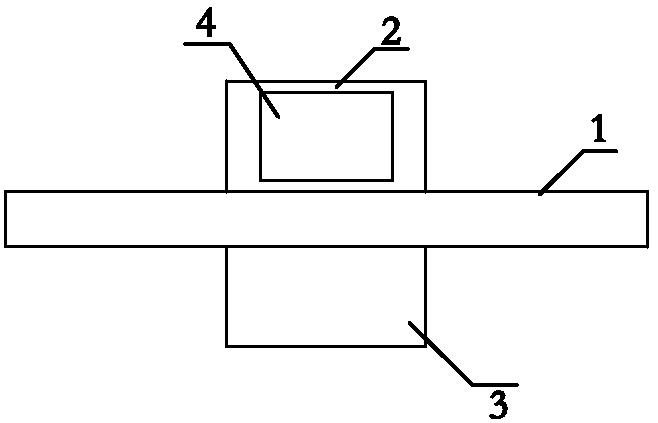

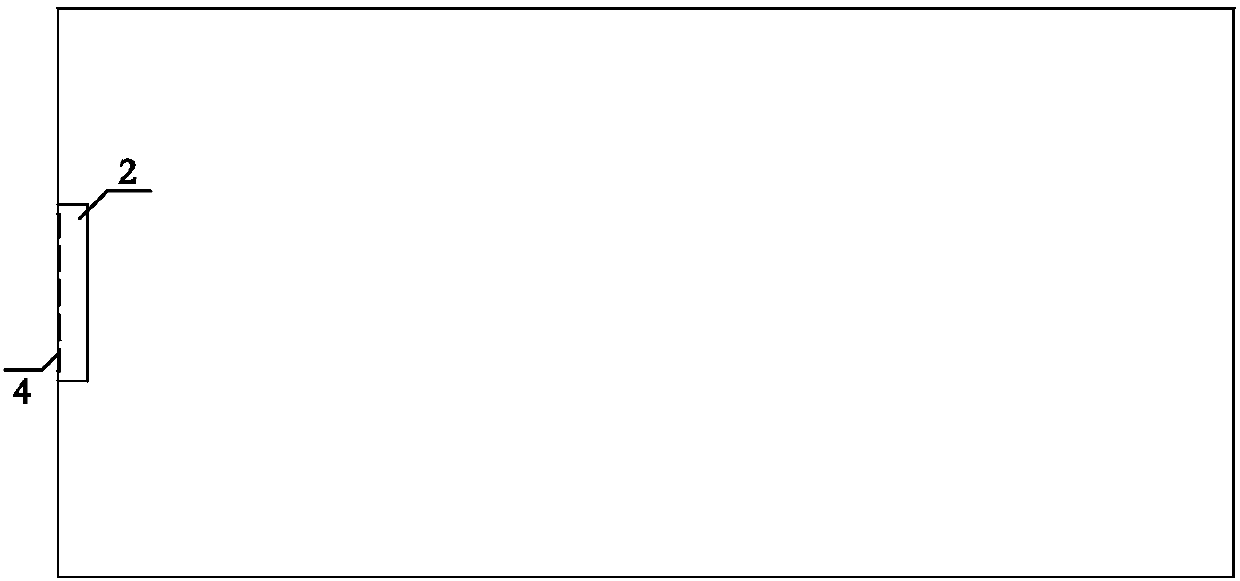

[0038] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings. Please note that the following embodiments are only illustrative of the present invention and are not intended to limit the scope of the present invention.

[0039] The present invention makes full use of high-performance new flexible plastic materials, such as EPP, graphene EPS or EPE materials, etc., to make hoisting and transportation protection components, which are specially designed for large transportation parts such as 3D printing buildings, structures and building components, and are of course also applicable to Other hoisting and transportation occasions.

[0040] The hoisting and transporting protective assembly of the present invention includes pallets that can be used alone or in combination, and protective pieces of various shapes. Pallets of different shapes and sizes and protective parts can be selected according to the volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com