Flue gas desulfurization and denitrification process

A technology for desulfurization, denitrification, and flue gas, which is applied in gas treatment, dispersed particle separation, membrane technology, etc. to save energy and reduce waste emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

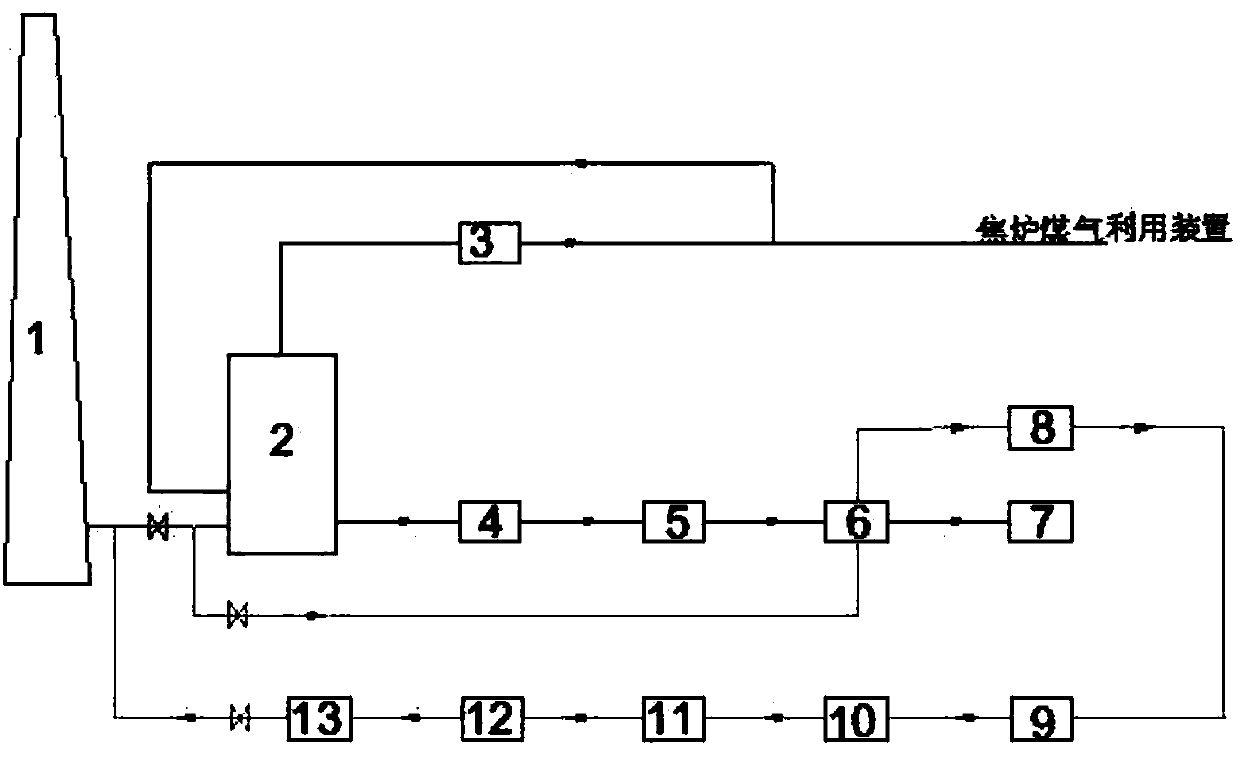

[0013] Embodiment 1, a flue gas desulfurization and denitrification process, comprising the following steps: the first step, the coke oven gas produced by the coke oven 2 is sent to the purification device 3 for treatment, and the treated purified gas is returned to the coke oven for combustion and heating, and the waste gas produced Discharge through the chimney 1, and the red coke produced simultaneously is packed into the coke tank 4; the second step, close the inlet valve of the chimney 1, open the inlet valve of the initial treatment tank 6 simultaneously, open the outlet of the induced draft fan 13 and open the induced draft fan 13; Three steps, put the red coke in the coke tank 4 into the loading device 5, put the red coke into the primary treatment tank 6 through the loading device 5, and control the temperature of the flue gas at the outlet of the primary treatment tank 6 at 220-450 °C, The coke is cooled to 220-190°C and sent to the coke discharge device 7; in the fou...

Embodiment 2

[0039] Embodiment 2, a flue gas desulfurization and denitrification process, comprising the following steps: the first step, the coke oven gas produced by the coke oven 2 is sent to the purification device 3 for treatment, and the treated purified gas is returned to the coke oven for combustion and heating, and the waste gas produced Discharge through the chimney 1, and the red coke produced simultaneously is packed into the coke tank 4; the second step, close the inlet valve of the chimney 1, open the inlet valve of the initial treatment tank 6 simultaneously, open the outlet of the induced draft fan 13 and open the induced draft fan 13; Three steps, put the red coke in the coke tank 4 into the loading device 5, put the red coke into the primary treatment tank 6 through the loading device 5, and spray NH into the primary treatment tank (6) at the same time X The temperature of the flue gas at the outlet of the primary treatment tank 6 is controlled at 220-850°C, and the red co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com