Bamboo charcoal insole and manufacturing method thereof

A bamboo charcoal and insole technology, applied in insoles, footwear, clothing, etc., can solve the problems of reduced functionality of bamboo charcoal, easy powder loss, easy damage of non-woven fabrics, etc., and achieves the effect of reducing waste discharge and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

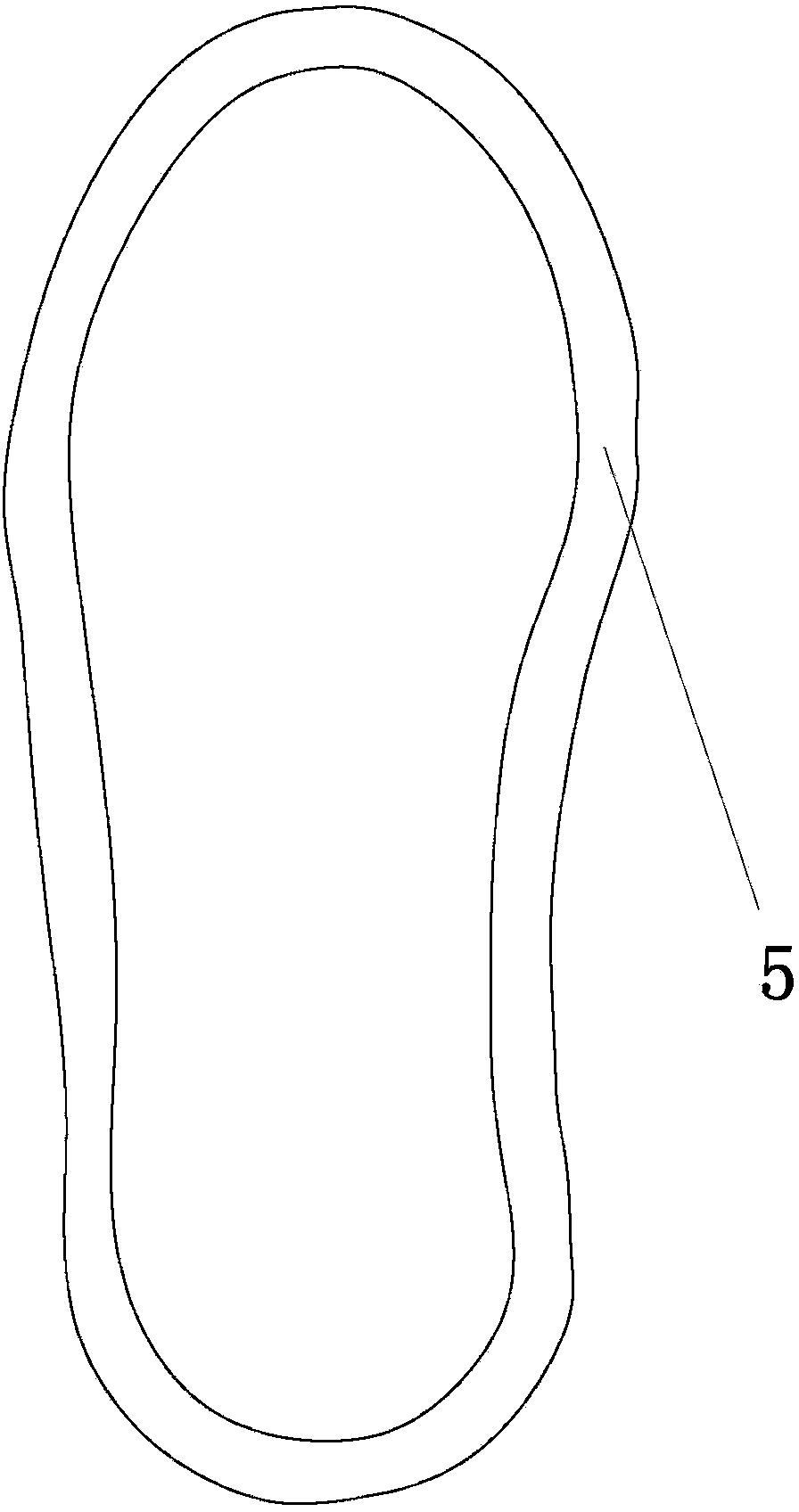

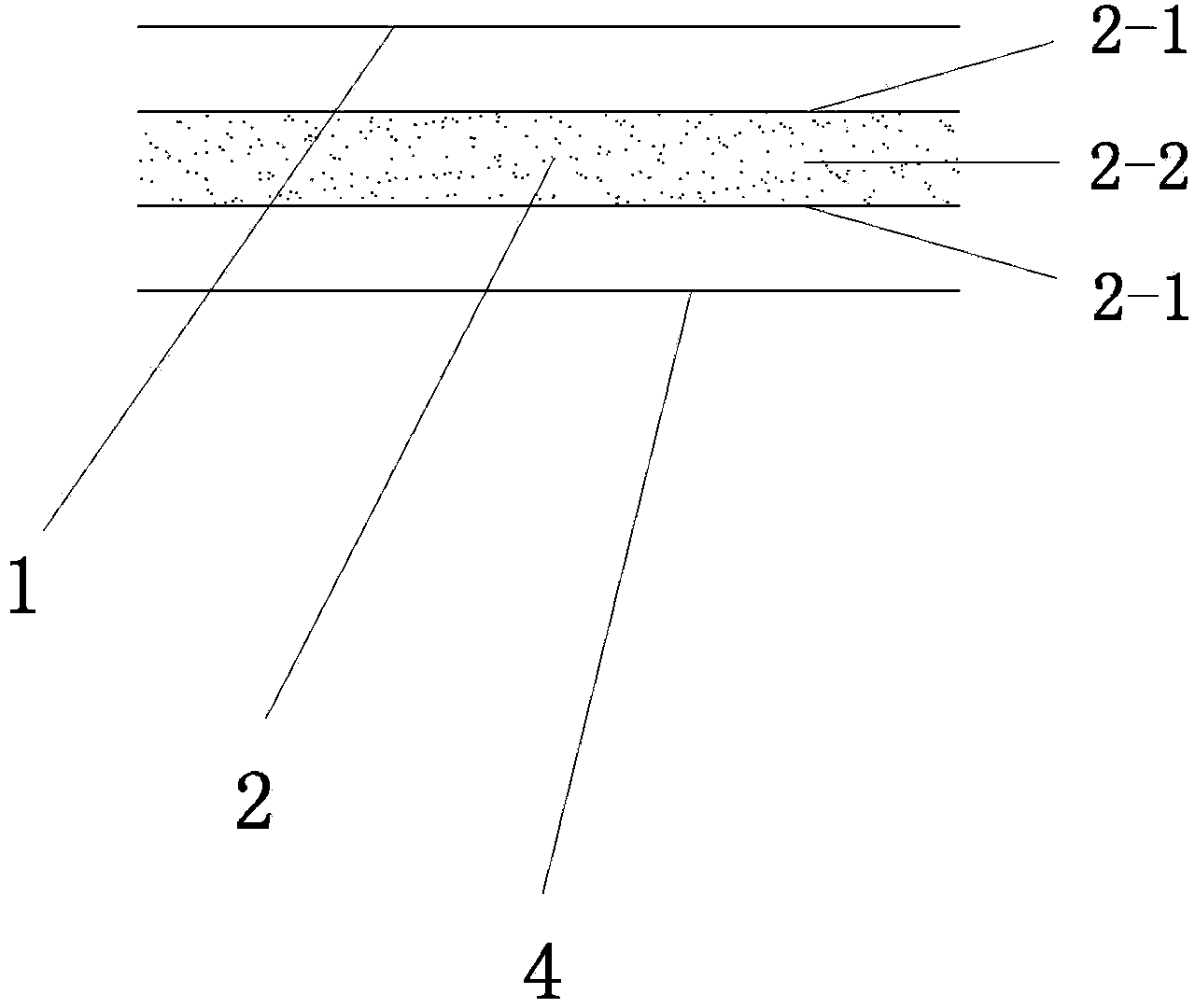

[0053] Such as figure 1 , 2 , Shown in 4,5, a kind of bamboo charcoal shoe-pad comprises bamboo fiber warp knitting surface layer 1, bamboo charcoal middle layer 2 and nonwoven fabric bottom layer 4. The bamboo charcoal middle layer 2 is formed by interposing bamboo charcoal powder 2-2 between two adhesive interlinings 2-1 and bonded and fixed; the bamboo fiber warp knitted surface layer 1 and the bamboo charcoal middle layer 2 pass through one of the adhesive interlinings. Interlining cloth 2-1 phase adhesion. The front side of the bamboo fiber warp-knitted surface layer 1 is formed with transversely raised weft thread anti-slip strips 1-1; the reverse side of the bamboo fiber warp-knitted surface layer 1 is formed with longitudinally raised warp thread adhesive strips 1-2. The weft anti-slip strip 1-1 and the warp adhesive strip 1-2 are arranged back to back. The weft anti-slip strip 1-1 at the same place is provided with 3 sections, and the warp thread adhesive strip 1-2...

Embodiment 2

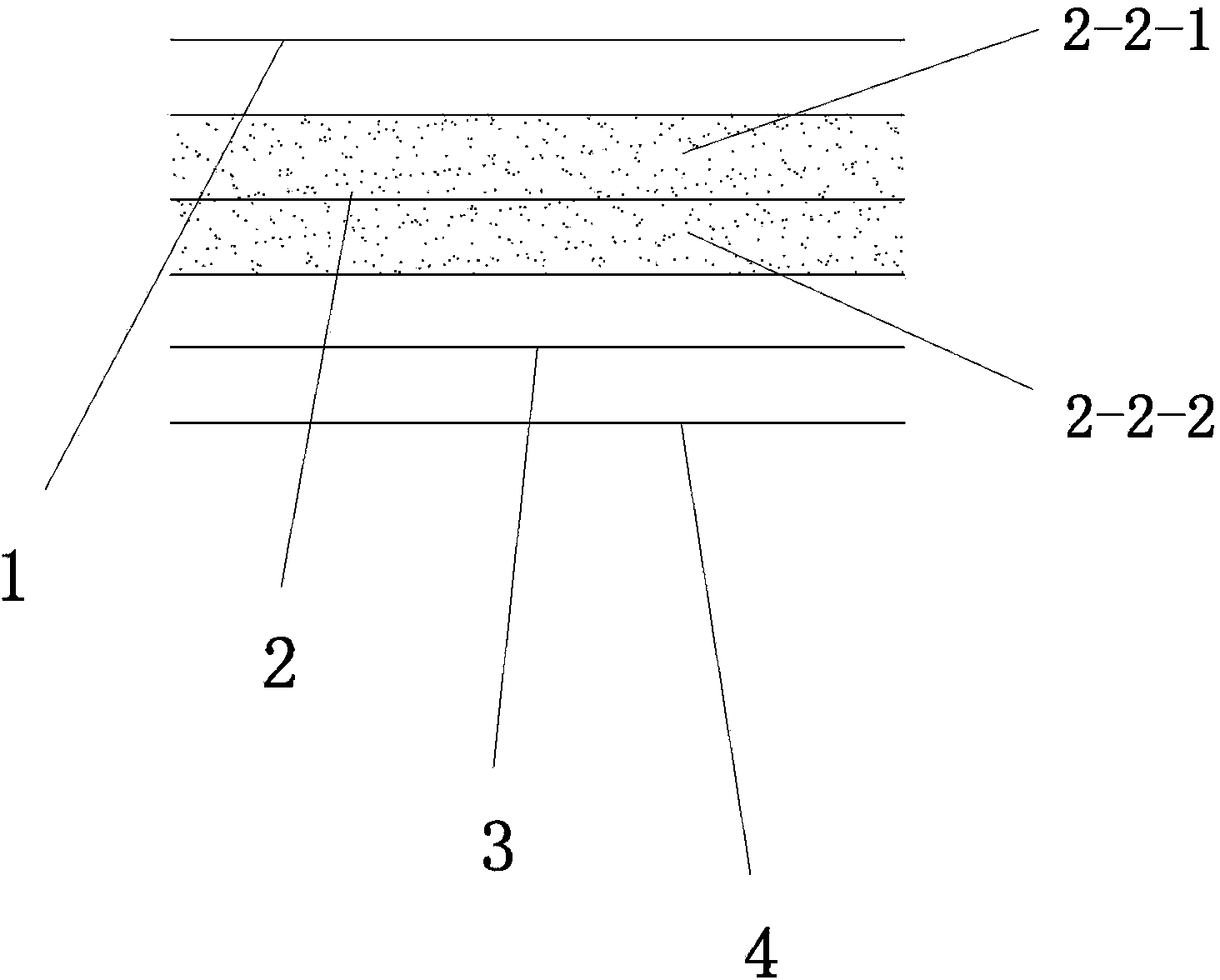

[0057] Such as figure 1 , 3 , Shown in 4,5, a kind of bamboo charcoal shoe-pad, comprise bamboo fiber warp knitting surface layer 1, bamboo charcoal middle layer 2, skeleton layer 3 and nonwoven fabric bottom layer 4. The bamboo charcoal middle layer 2 is formed by bonding and fixing bamboo charcoal powder 2-2 between three adhesive interlinings 2-1;

[0058] Two layers of bamboo charcoal powder 2-1 are sandwiched between three adhesive interlinings 2-1 to form a sandwich structure. The bamboo fiber warp-knitted surface layer 1 and the bamboo charcoal middle layer 2 are bonded by one of the adhesive interlinings 2-1. The front side of the bamboo fiber warp-knitted surface layer 1 is formed with transversely raised weft thread anti-slip strips 1-1; the reverse side of the bamboo fiber warp-knitted surface layer 1 is formed with longitudinally raised warp thread adhesive strips 1-2. The weft anti-slip strip 1-1 and the warp adhesive strip 1-2 are arranged back to back. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com