Polycarbonate composition and preparation method thereof

A technology of polycarbonate and composition, which is applied in the field of engineering plastics, can solve the problems of easy color change, long-term thermal-oxidative aging performance of double bonds, hidden dangers of weather resistance, and easy formation of defects on the surface, so as to improve thermal-oxidative stability. Effect

Inactive Publication Date: 2018-03-13

KINGFA SCI & TECH CO LTD +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Polycarbonate PC has high impact resistance and heat resistance. In order to improve its processing performance and the shortcomings of notch impact sensitivity, rubber modified polymers, such as ABS, MBS, etc., can usually be added, especially PC The PC / ABS alloy with ABS as the main raw material is an important engineering plastic, which can combine the excellent properties of the two to improve the physical properties and processing performance. However, due to the addition of ABS, the double bond in the system will bring long-term The hidden dangers of thermal oxygen aging performance and weather resistance performance, especially in the occasions with relatively high requirements for the use environment, the surface is prone to defects and its color is prone to change

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

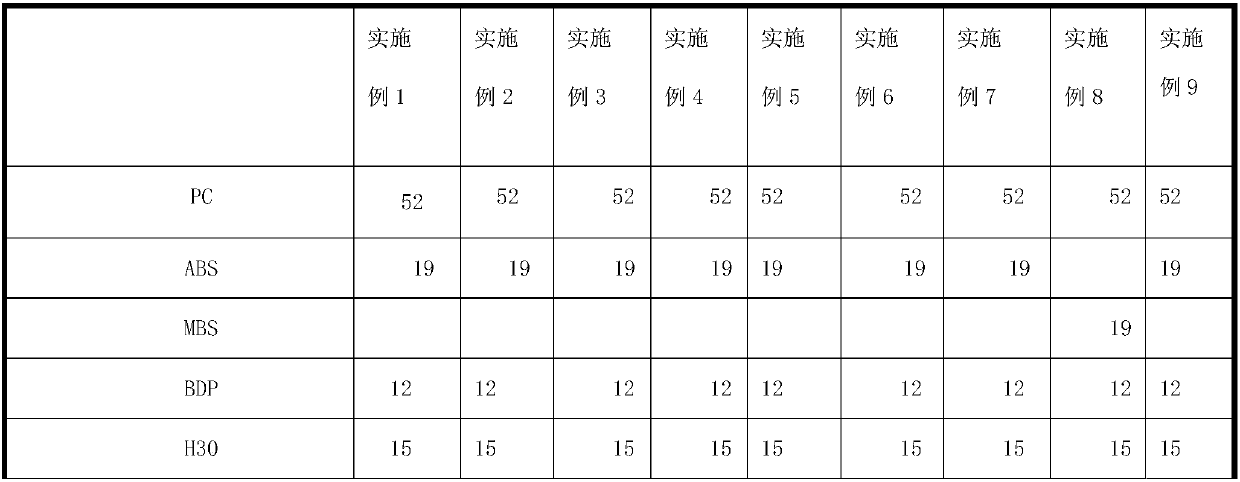

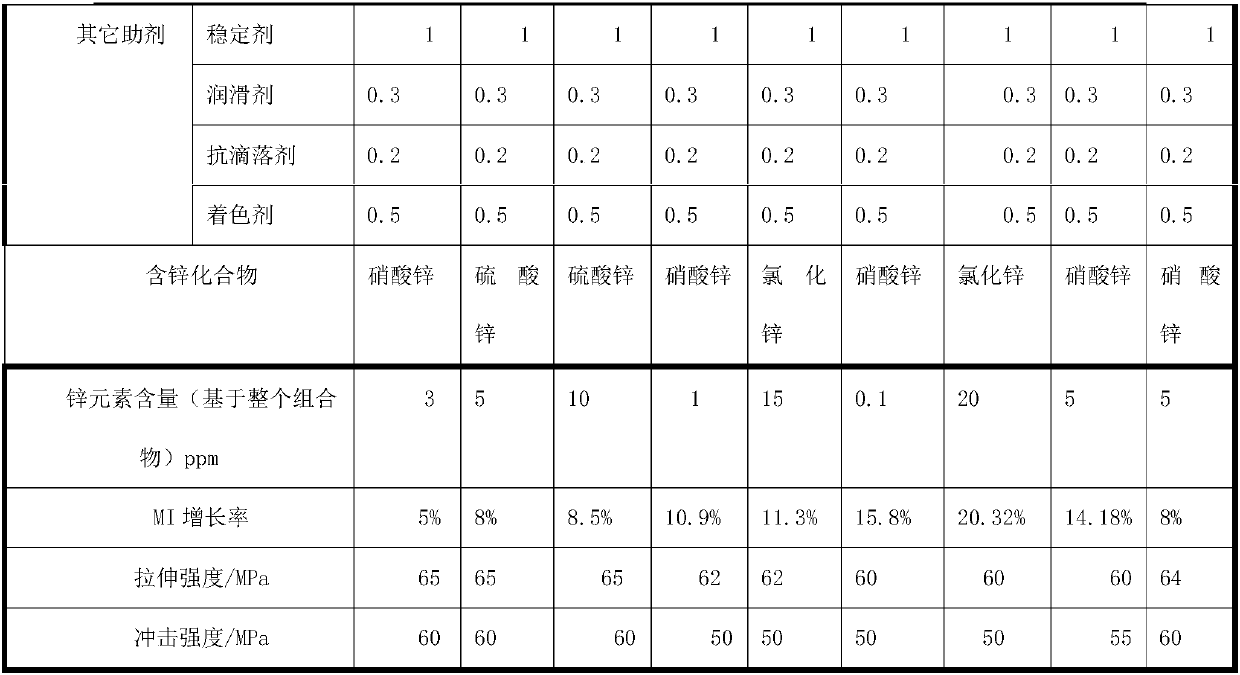

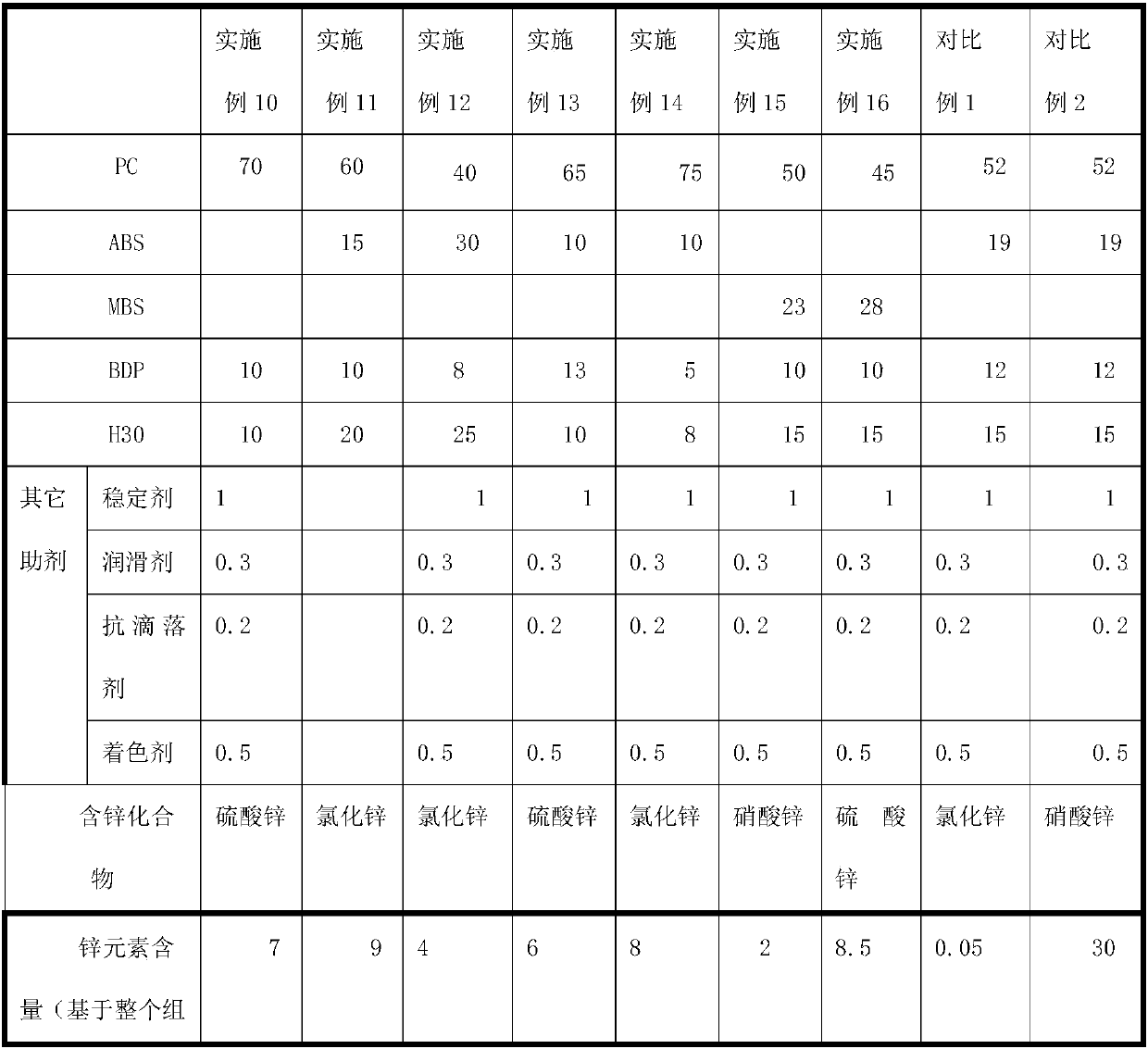

Embodiment 1-16 and comparative example 1-2

[0063] Embodiment 1-16 and comparative example 1-2: the preparation of polycarbonate composition

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a polycarbonate composition and a preparation method thereof. The polycarbonate composition comprises, by weight, 40 to 75 parts of polycarbonate, 0 to 35 parts of a graft copolymer, 5 to 30 parts of a flame retardant and 8 to 45 parts of a mineral filler. Based on the total weight of the polycarbonate composition, the zinc element weight content is 0.1 ppm to 20 ppm. Through use of the zinc-containing compound having low soluble zinc content in the polycarbonate composition and reduction or prevention of other zinc-containing compounds, the zinc content of the polycarbonate composition is controlled in a range of 0.1-20 ppm so that the prepared polycarbonate composition has a hot oxygen-aged MI growth rate of less than 30% after being aged at 80 DEG C for 500h andmarkedly improved thermal oxygen stability.

Description

technical field [0001] The invention relates to the technical field of engineering plastics, in particular to a polycarbonate composition and a preparation method thereof. Background technique [0002] Polycarbonate PC has high impact resistance and heat resistance. In order to improve its processing performance and the shortcomings of notch impact sensitivity, rubber modified polymers, such as ABS, MBS, etc., can usually be added, especially PC The PC / ABS alloy with ABS as the main raw material is an important engineering plastic, which can combine the excellent properties of the two to improve the physical properties and processing performance. However, due to the addition of ABS, the double bond in the system will bring long-term The hidden dangers of thermal oxygen aging performance and weather resistance performance, especially in the occasions with relatively high requirements on the use environment, the surface is prone to form defects and its color is prone to change...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L69/00C08L55/02C08L51/04C08L27/18C08K13/02C08K5/523C08K3/34C08K5/103C08K3/04

Inventor 岑茵艾军伟田征宇李明昆谢修好佟伟丁超谢湘

Owner KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com