Fresh air purifying method and equipment

A fresh air, chemical adsorption technology, applied in mechanical equipment, lighting and heating equipment, heating methods, etc., can solve difficult problems, achieve the effect of protecting cleanliness and prolonging working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The "top" mentioned in the present invention is relatively speaking and refers to the roof facing the building or structure.

[0018] In the present invention, unless otherwise specified, all the technical features and preferred technical features mentioned herein can be combined with each other to form a new technical solution.

[0019] In the present invention, unless otherwise specified, all the embodiments and preferred embodiments mentioned herein can be combined with each other to form new technical solutions.

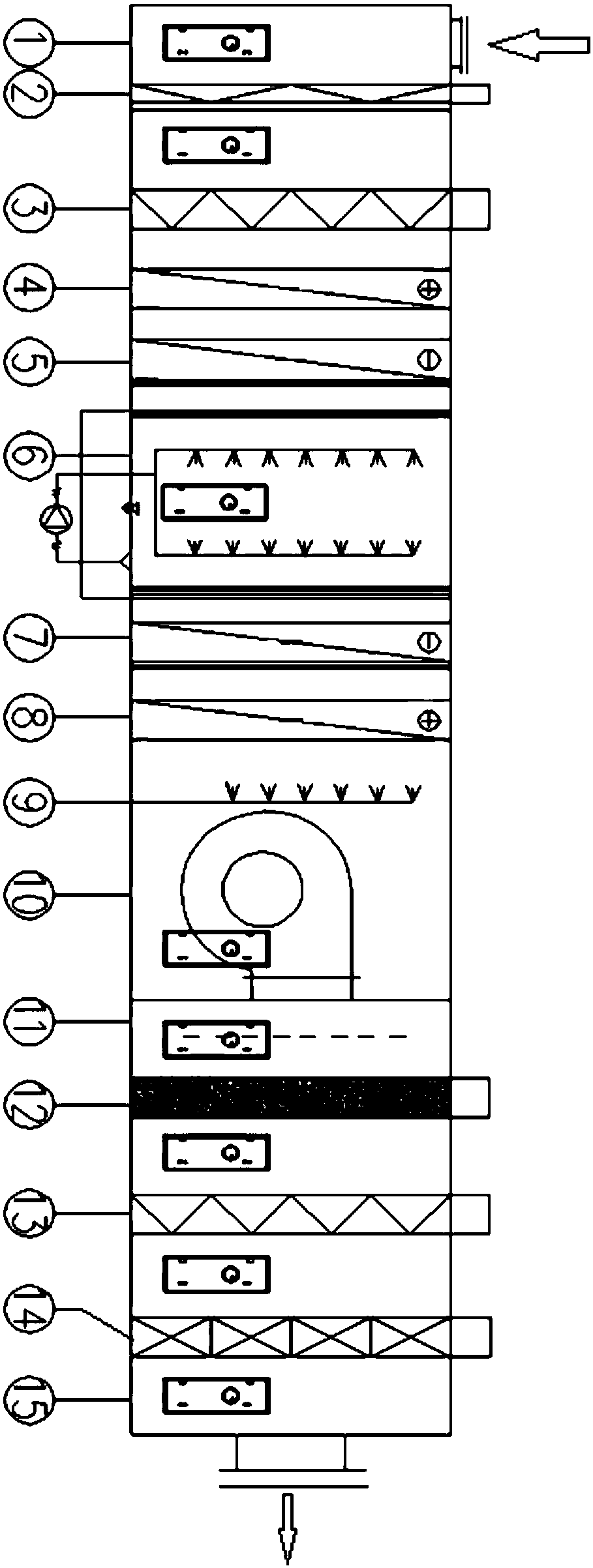

[0020] figure 1 A schematic diagram according to an embodiment of the invention is shown. lie in figure 1 The uppermost one is the air inlet section 1, and the arrow shows the direction of the fresh air inlet. In actual installation, it can be located on the far left or right, and the air can be taken in from the top, or from other places known to those skilled in the art. In this figure the air inlet is on the right. According to an embodiment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com