Pressure gauge batch metering and verifying system and method

A technology of measurement verification and pressure gauge, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of inability to realize digitalization, low efficiency of pressure gauge measurement verification, high probability of error introduction, etc., to achieve rich content and improve labor efficiency , the effect of increased likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

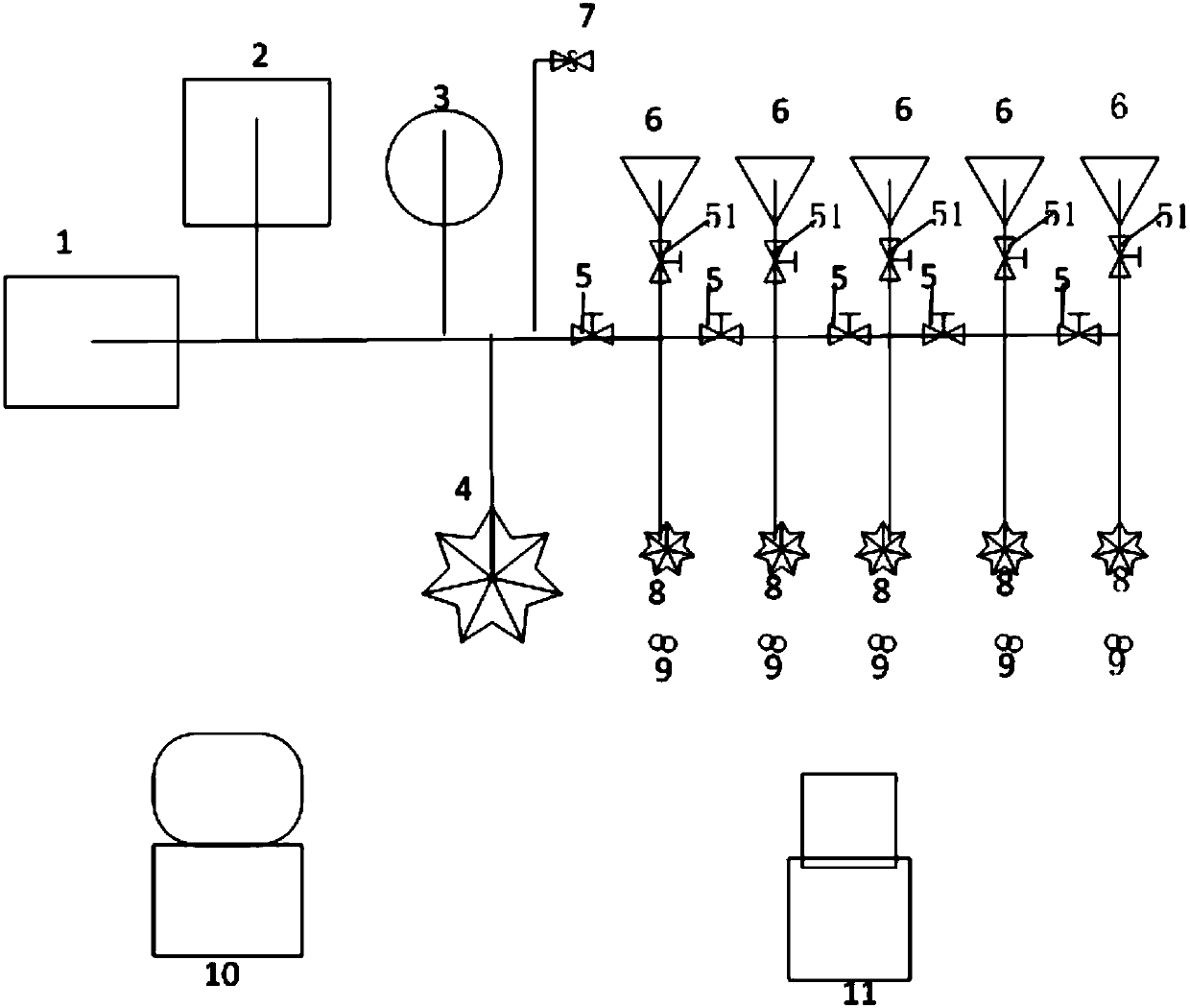

[0051] From figure 1 It can be seen that the verification system of this embodiment includes a preloading device 1, a medium container 2, a digital precision pressure gauge 3, a manual fine-tuning preloading hand pump 4, and a pressure relief valve 7, which are sequentially arranged on the pressure pipeline. A cut-off valve 5 and a second cut-off valve 51, the tested meter joint 6, the single-meter fine-tuning hand pump 8 and the collection key 9, the tested meter joint 6 in the present embodiment, that is, the clamping device of the tested meter is five, That is, five precision pressure gauges with the same range can be connected at the same time for measurement verification, and the number of joints of the tested meters can be increased according to actual needs. Each tested meter corresponds to a first cut-off valve 5, a second cut-off valve 51, A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com