As2SexS3-x ternary semiconductor core composite optical fiber with phosphate glass cladding, and preparation method for As2SexS3-x ternary semiconductor core composite optical fiber

A technology of phosphate glass and composite optical fiber, which is applied in cladding optical fiber, optical waveguide and light guide, etc., can solve the problems of difficult to form stable glass state and harsh conditions, and achieve large-scale industrial production, high nonlinearity, and good photoelectricity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Phosphate glass clad As 2 Se x S 3-x (x=0.5) the preparation of ternary semiconductor core composite optical fiber, concrete steps are as follows:

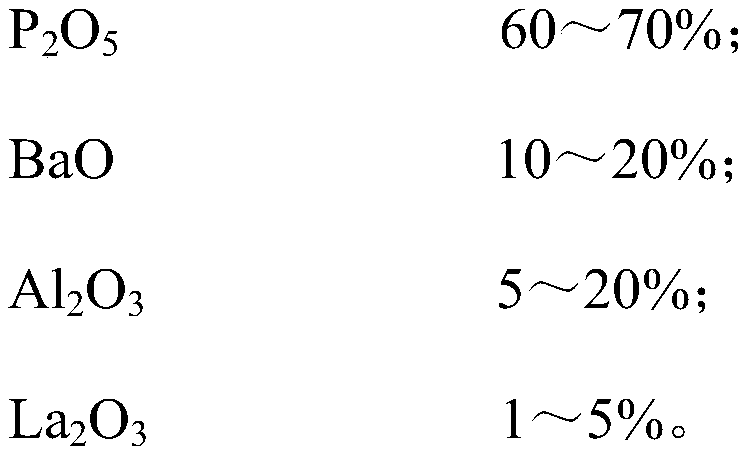

[0032] (1) Melting of phosphate glass cladding: adopt traditional melting-annealing method to melt block phosphate glass, by weight percentage, the raw material composition of phosphate glass cladding is as follows:

[0033]

[0034] Weigh the raw materials according to the ratio, mix them evenly, add them to a corundum crucible and melt them at 1200°C, and obtain bulk phosphate glass after precision annealing;

[0035] (2) Machining of phosphate glass: After precision annealing, the bulk glass cladding is processed into a phosphate glass cylinder with a diameter of Φ20mm and a length of 120mm, and then a 3mm diameter cylinder is drilled in the middle of the phosphate glass cylinder along the axis of the cylinder. The round hole, the surface of the phosphate glass cylinder and the inner surface of the round hole are m...

Embodiment 2

[0040] Phosphate glass clad As 2 Se x S 3-x (x=1) the preparation of ternary semiconductor core composite optical fiber, concrete steps are as follows:

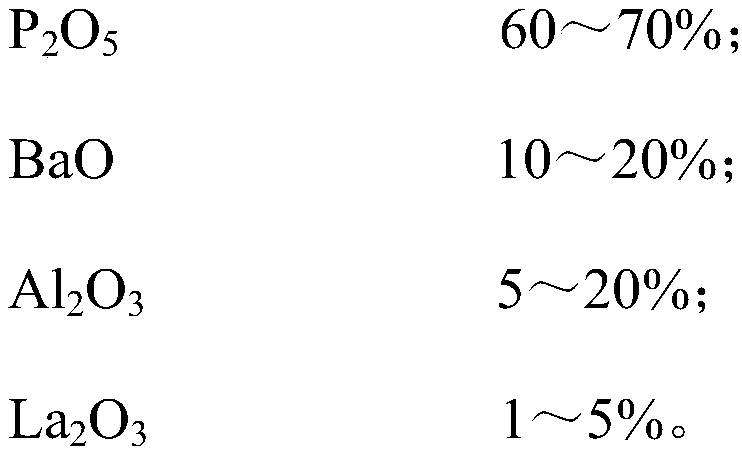

[0041] (1) Melting of phosphate glass cladding: adopt traditional melting-annealing method to melt block phosphate glass, by weight percentage, the raw material composition of phosphate glass cladding is as follows:

[0042]

[0043]

[0044] Weigh the raw materials according to the ratio, mix them evenly, add them to a corundum crucible and melt them at 1100°C, and obtain bulk phosphate glass after precision annealing;

[0045] (2) Machining of phosphate glass: After precision annealing, the bulk cladding glass is processed into a phosphate glass cylinder with a diameter of Φ20mm and a length of 120mm, and then a round hole with a diameter of 3mm is drilled in the middle of the phosphate glass cylinder along the axis of the cylinder. The phosphate glass cylindrical surface and the inner surface of the hole are mecha...

Embodiment 3

[0050] Phosphate glass clad As 2 Se x S 3-x (x=1.5) the preparation of ternary semiconductor core composite optical fiber, concrete steps are as follows:

[0051] (1) Melting of phosphate glass cladding: adopt traditional melting-annealing method to melt block phosphate glass, by weight percentage, phosphate glass cladding is raw material composition as follows:

[0052]

[0053] Weigh the raw materials according to the ratio, mix them evenly, add them to a corundum crucible and melt them at 1200°C, and obtain bulk phosphate glass after precision annealing;

[0054] (2) Mechanical processing of phosphate glass: after precision annealing, the bulk cladding glass is processed into a phosphate glass cylinder with a diameter of Φ20mm and a length of 120mm, and then a round hole with a diameter of 3mm is drilled in the middle of the phosphate glass cylinder along the axis of the cylinder. The phosphate glass cylindrical surface and the inner surface of the hole are mechanical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com