Carrying device auxiliary system capable of achieving big data collection management

An auxiliary system and big data technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as safety liability accidents, achieve stable operation, avoid mistakes in human judgment, and low design and use costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

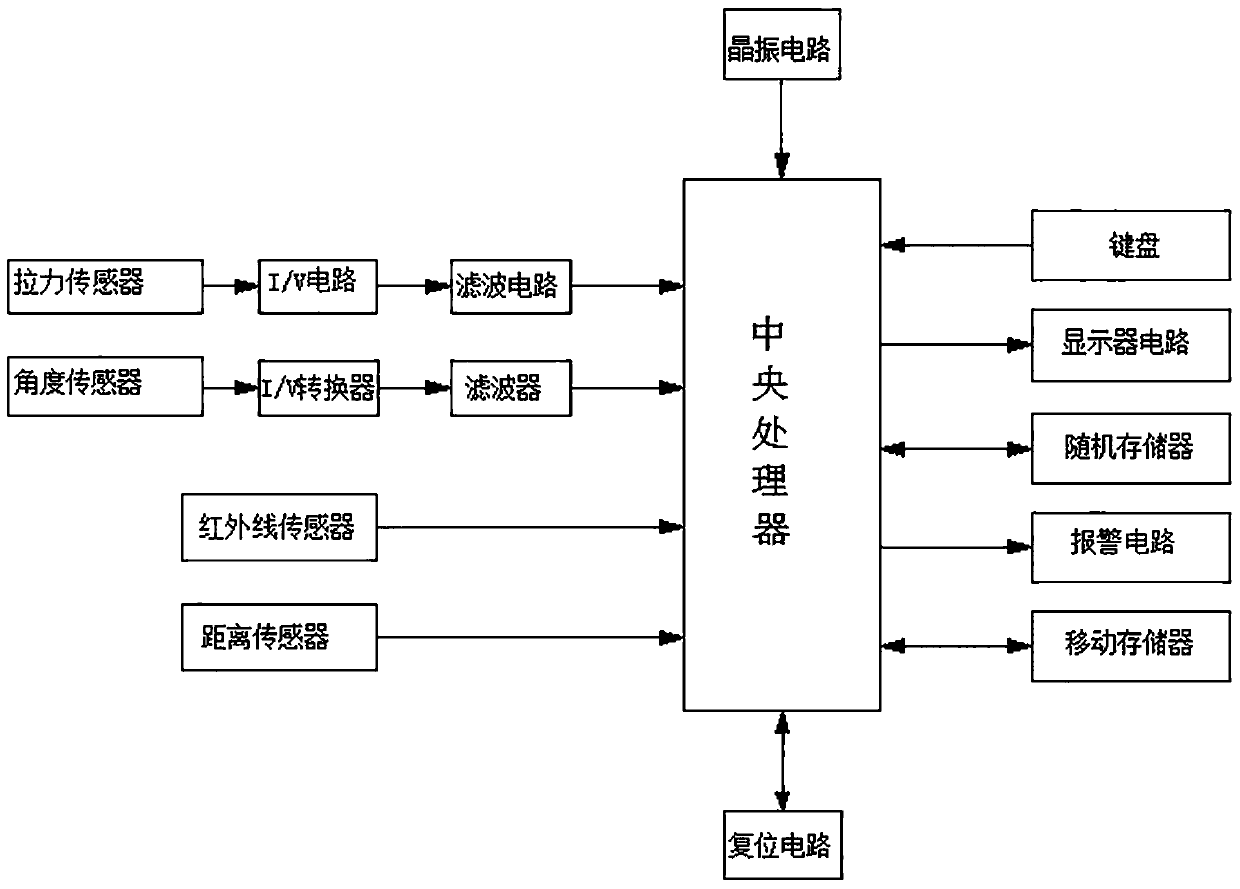

[0035] An auxiliary system for carrying equipment that can realize big data collection and management, using sensor technology to convert non-electric power (pull force, angle, etc.) It can safely and quickly displace the object, so as to solve the shortcomings of the existing technology that need to be manually viewed and the point of view is not punctual, which is prone to safety liability accidents; when converting the signal output by the angle sensor, through the integrated operation The I / V converter designed for the amplifier converts the current to the voltage signal, converts the current signal of about 4-20mA into a voltage signal of 0-2.5V suitable for the central processing unit, and then sends it to the AD of the central processing unit after filtering. Subsequent processing is carried out in the circuit, and the whole system, especially the angle sensor circuit, is simple to design the circuit to realize the required functions. It has the advantages of low design ...

Embodiment 2

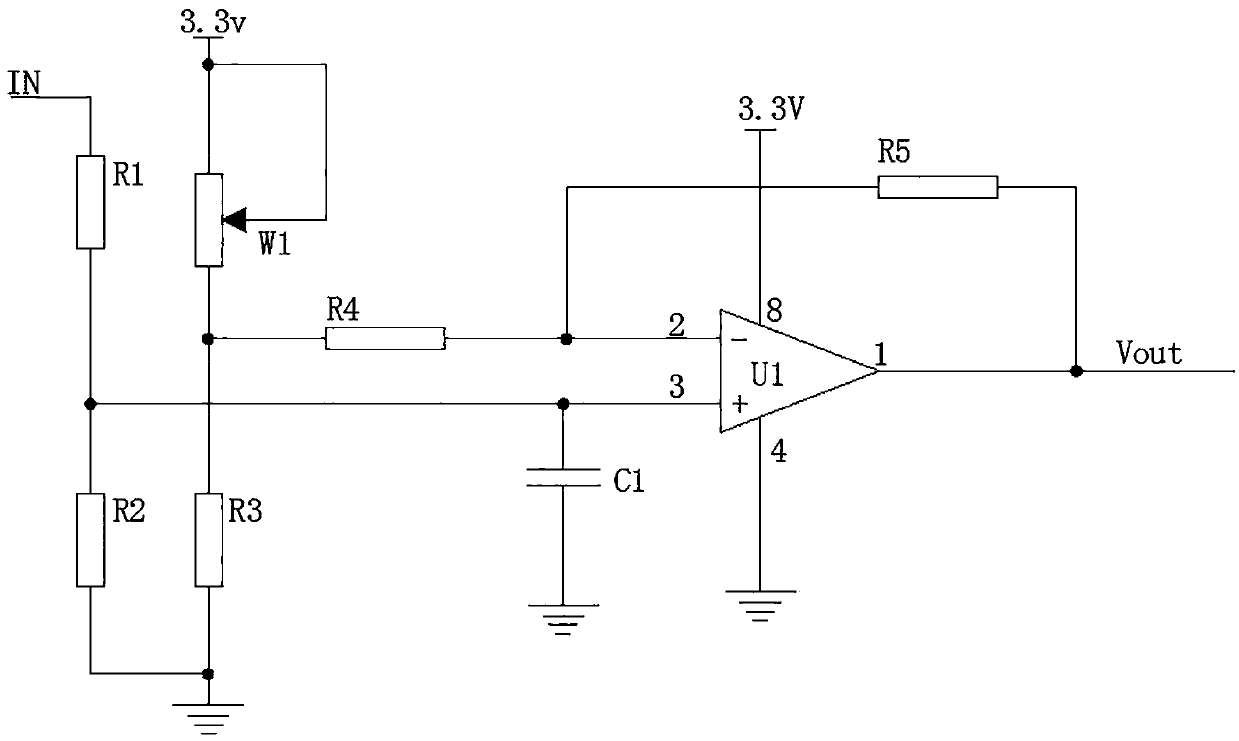

[0039] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 , figure 2 As shown, further in order to better realize the present invention, the following arrangement structure is adopted in particular: the inverting input circuit includes resistor R1 and resistor R2, the non-inverting input circuit includes potentiometer W1, resistor R4 and resistor R3, and the resistor R1 and resistor R2 are connected in series with each other and the resistor R1 and resistor R2 connected in series are connected between the output terminal of the angle sensor and the ground, and the non-inverting input terminal of the integrated operational amplifier U1 is connected to the common terminal of the resistor R1 and the resistor R2; the potentiometer W1 and resistor R3 are connected in series with each other and connected between the power supply of the angle sensor circuit and the ground. The common terminal of the potentiometer W1 and the resistor R3 is co...

Embodiment 3

[0041] This embodiment is further optimized on the basis of any of the above embodiments, such as figure 1 , figure 2 As shown, further in order to better realize the present invention, the following arrangement structure is adopted in particular: a fixed end of the potentiometer W1 is connected to the power supply of the angle sensor circuit, and the power supply of the angle sensor circuit adopts 3.3V direct current , the integrated operational amplifier U1 adopts LMV358, and the angle sensor adopts BROSA-0802 angle sensor.

[0042] When designing and using, the angle sensor BROSA-0802 collects the elevation angle signal of the main arm (real-time detection value), and then forms a current signal of about 4-20mA, and converts it into a 0-2.5V suitable for the central processing unit through the I / V converter The voltage signal is finally sent to the filter for filtering, and then sent to the central processing unit. The central processing unit sends an adjustment signal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com