Capacitor explosion-proof block

An explosion-proof block and capacitor technology, applied in capacitors, electrical components and other directions, can solve the problems of poor explosion-proof effect, low safety factor, inconvenient welding, etc., and achieve the effects of easy welding, long service life, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

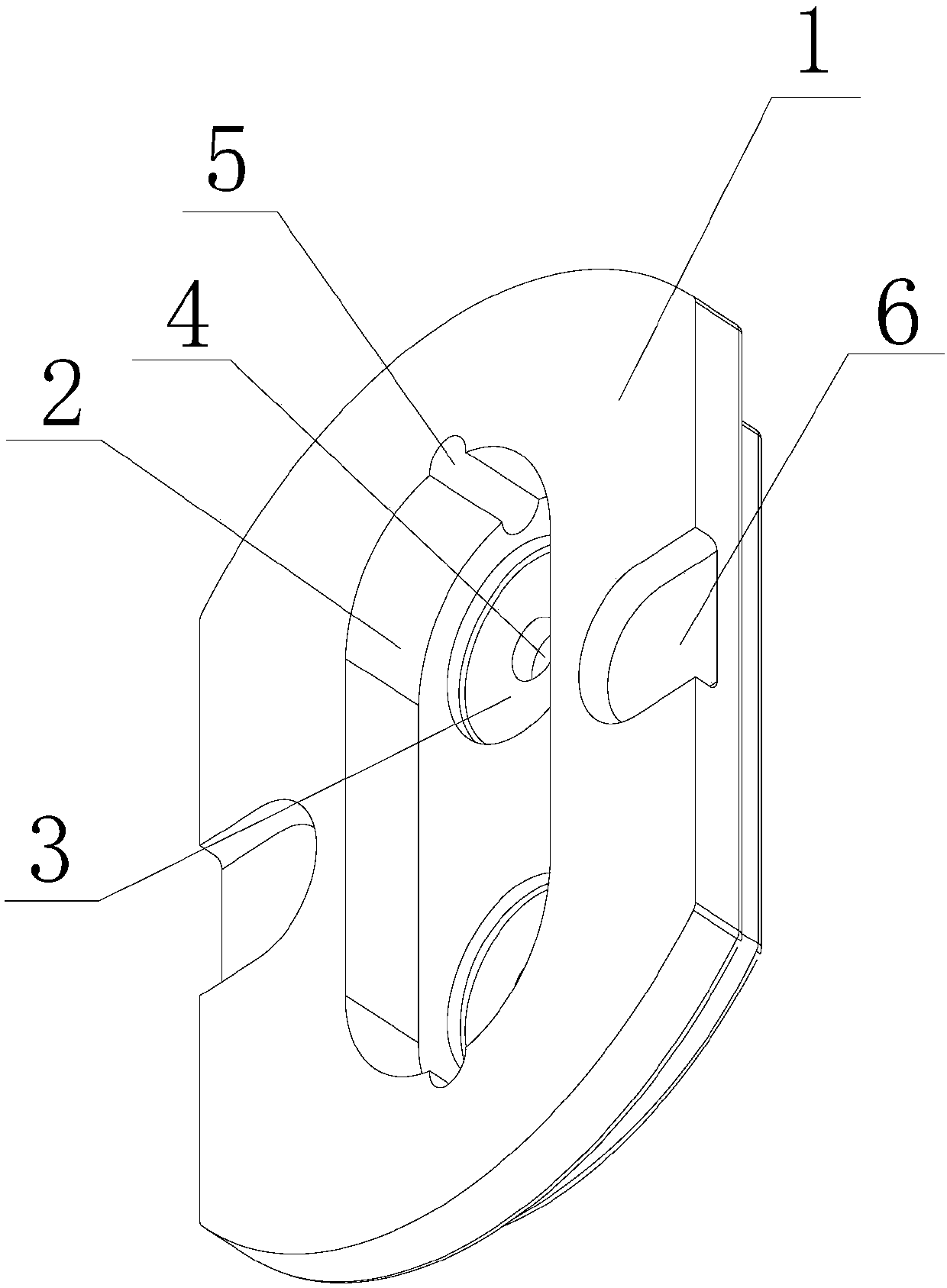

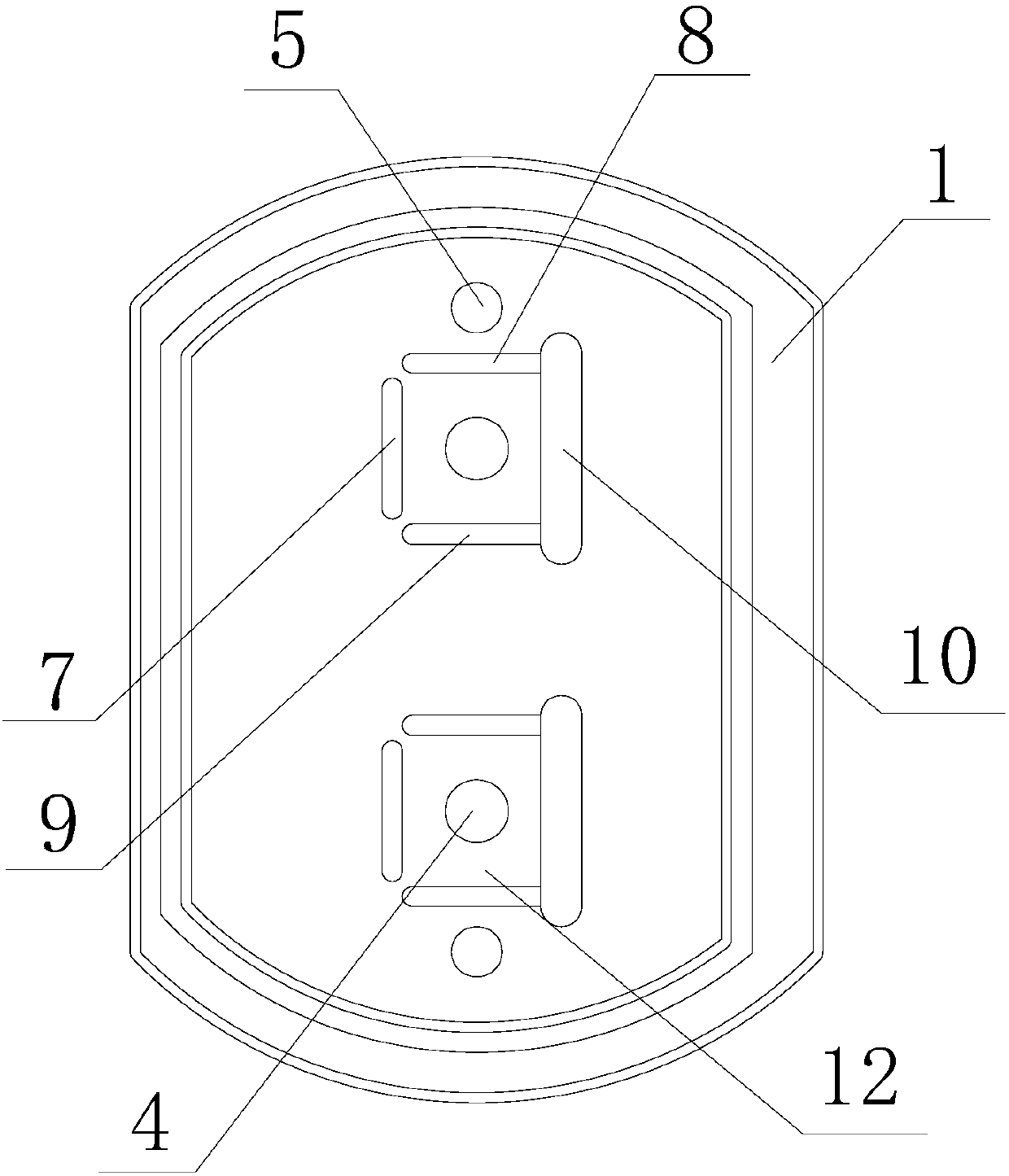

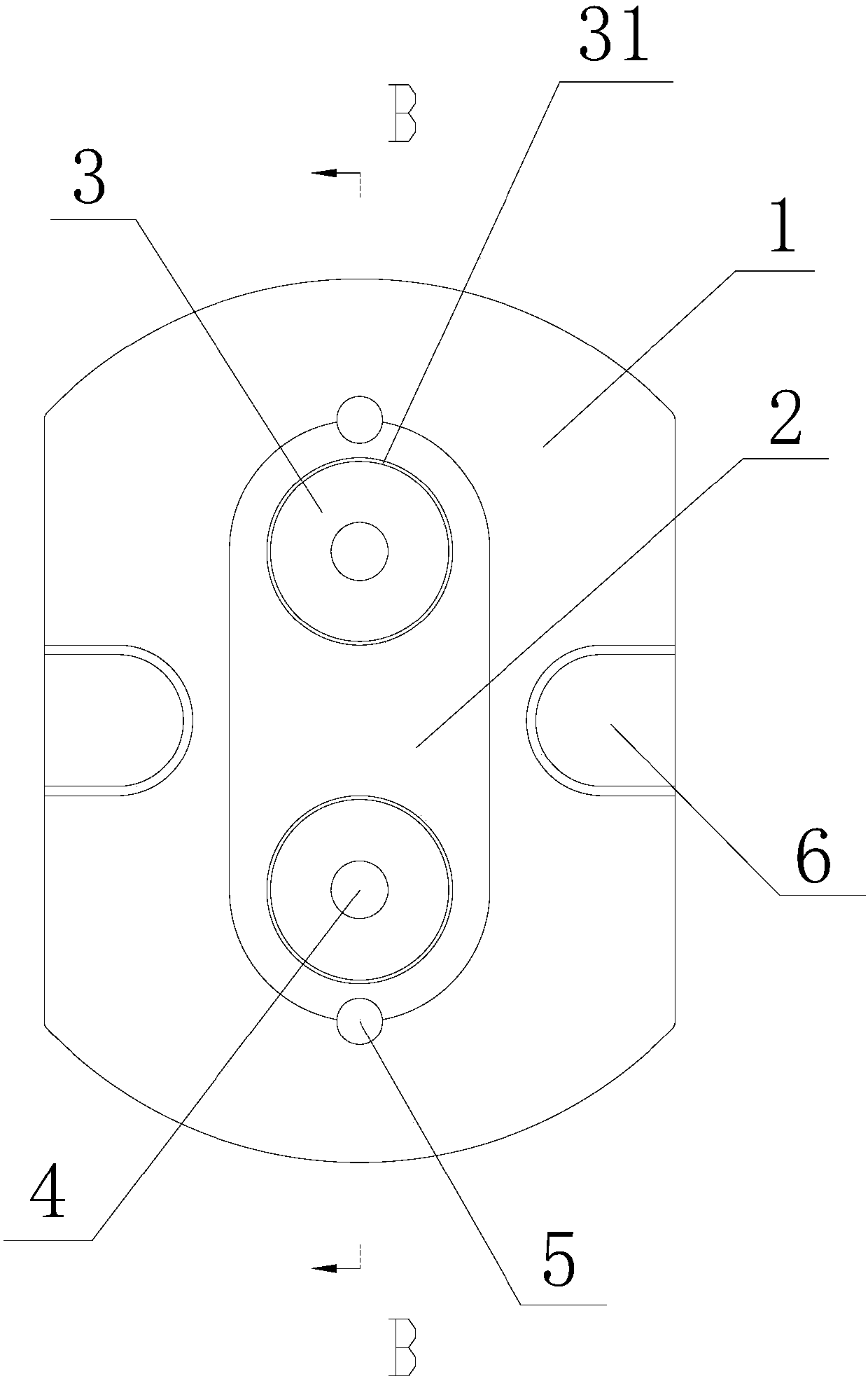

[0023] refer to Figure 1 to Figure 4 , the present invention provides an explosion-proof block for capacitors, including an explosion-proof block body 1, the explosion-proof block body 1 should have rigidity, that is, the explosion-proof block does not deform when the cover is deformed under pressure, in this embodiment, the explosion-proof block body 1 is made of PBT PBT is one of the toughest engineering thermoplastic materials. It is a semi-crystalline material with very good chemical stability, mechanical strength, electrical insulation properties and thermal stability; the upper end of the explosion-proof block body 1 is provided with a mounting cavity 2 , the installation cavity 2 is waist-circular, the shape of the installation cavity 2 determines the shape of the cardboard, and the bottom of the installation cavity 2 is symmetrically provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com