Camera component with automatic cleaning function

A camera component and automatic cleaning technology, which is applied in the field of cameras, can solve the problems of easily polluting the lens, affecting the daily management of managers, and the limited viewing angle of the camera, so as to prevent pollution and prevent the lens from being scratched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

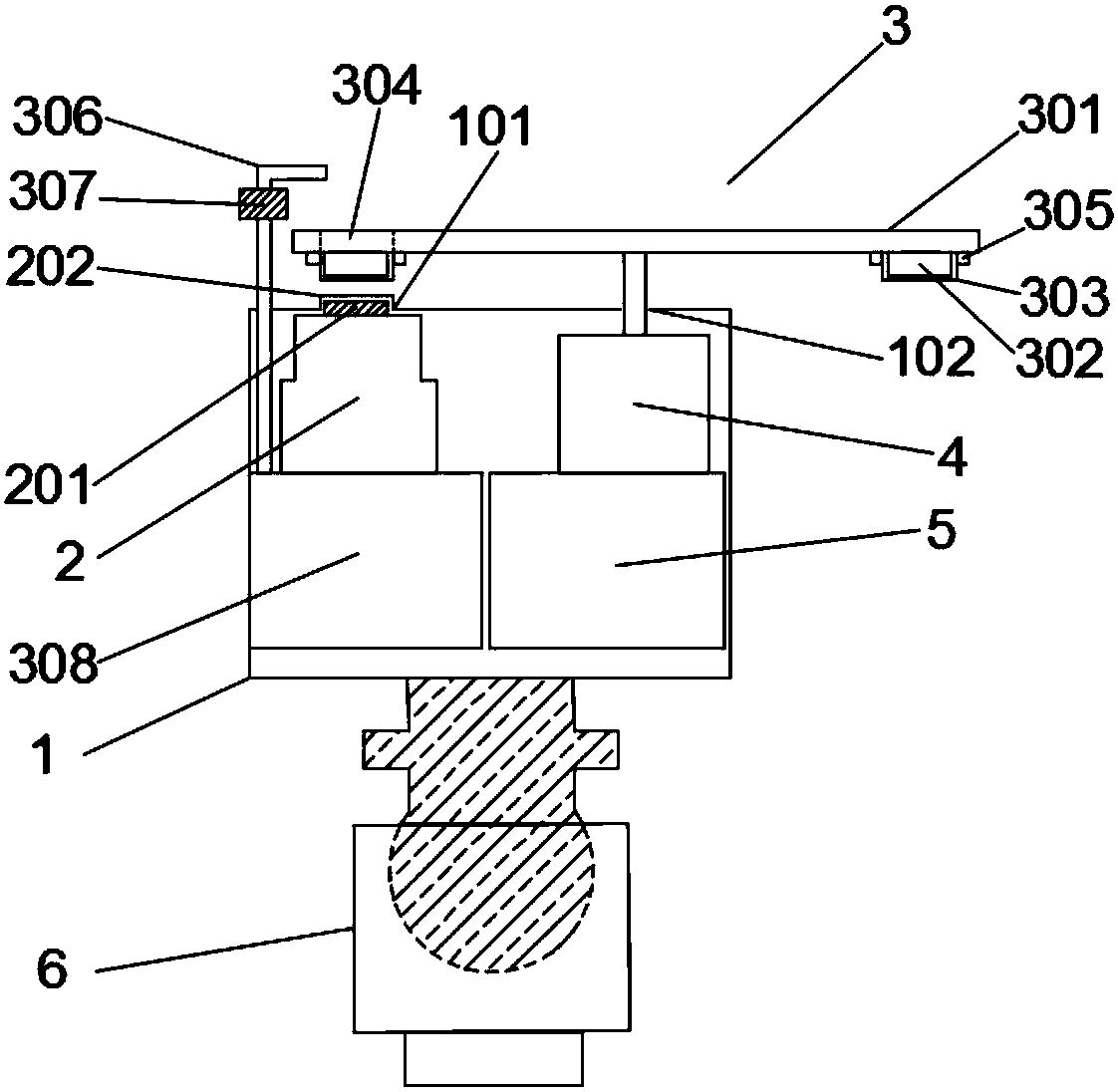

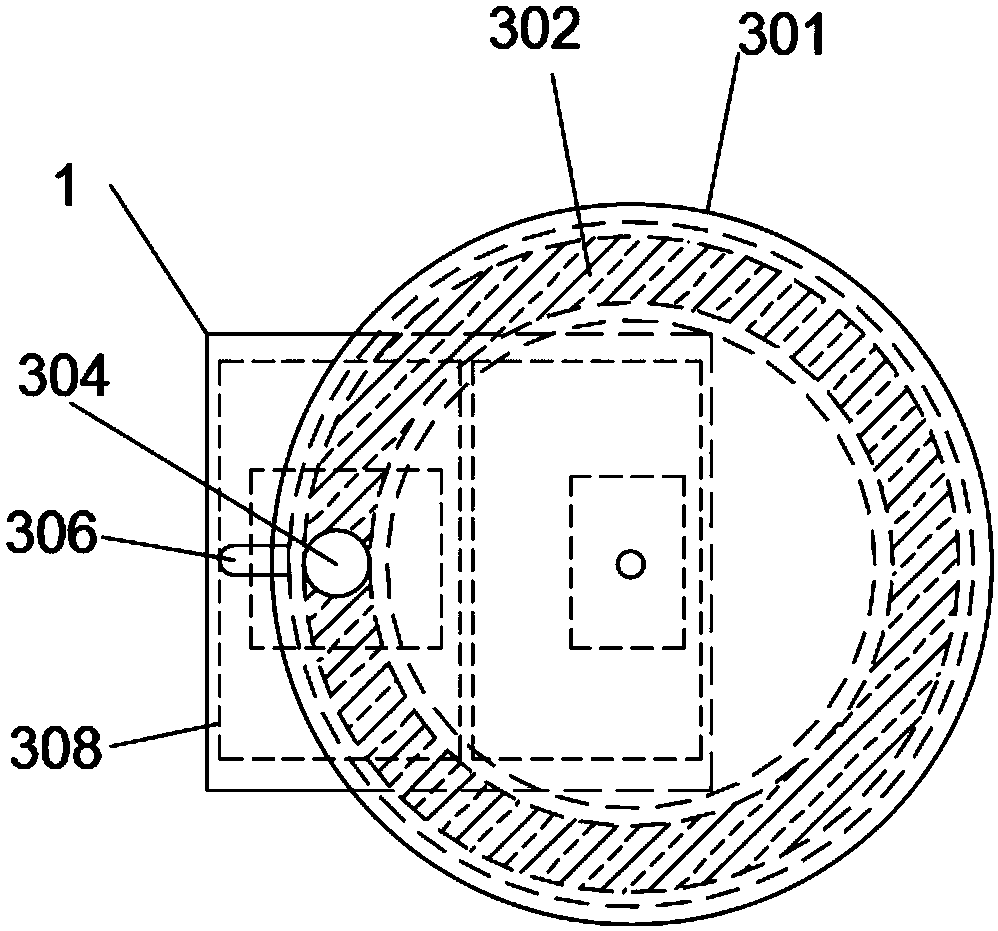

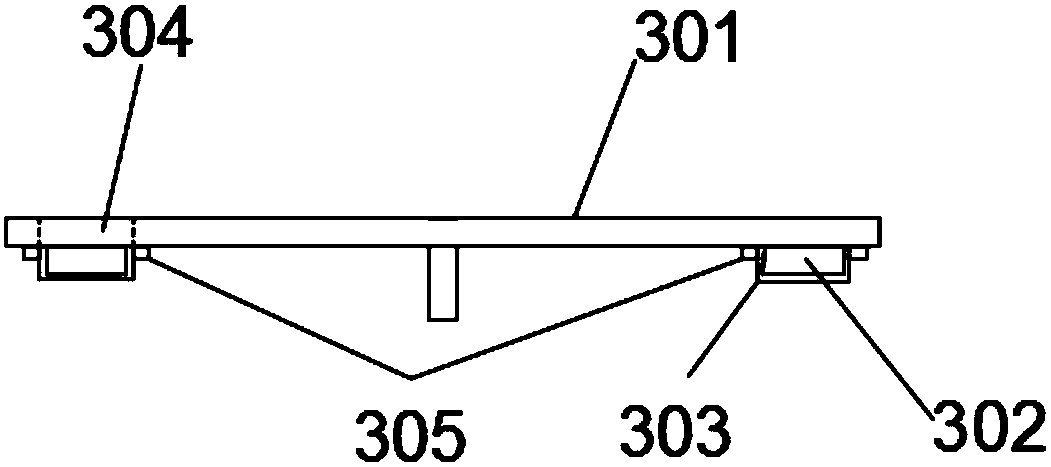

[0027] A camera assembly with an automatic cleaning function, comprising a sealed box 1, a camera module 2, a cleaning module 3, a motor module 4, a controller 5, and an electric universal joint 6; the camera module 2, a liquid storage bin 308. Both the motor module 4 and the controller 5 are set in the sealed box 1, the top surface of the sealed box 1 is provided with a first small hole 101 and a second small hole 102, and the camera The lens 201 of the module 2 is embedded in the first small hole 101, and a detachable protective cover 202 is provided on the first small hole; the turntable 301 of the cleaning module 3 is set in the sealed box 1 In addition, the rotating shaft of the motor module 4 is vertically connected to the center of the turntable 301 through the second small hole 102, and the turntable 301 is provided with a circle of sponge ring 302, and the surface of the sponge ring 302 is wrapped with a cleaning cloth 303, The detachable pressing block 305 is pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com