Seedling tray conveying mechanism used on green Chinese onion transplanter

A seedling tray conveying and transplanting machine technology, applied in the direction of transplanting machinery, application, planting methods, etc., can solve the problems of complexity, huge machinery, unfavorable operation, etc., and achieve simple conveying mechanism, reduce complex structure, and occupy a small space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

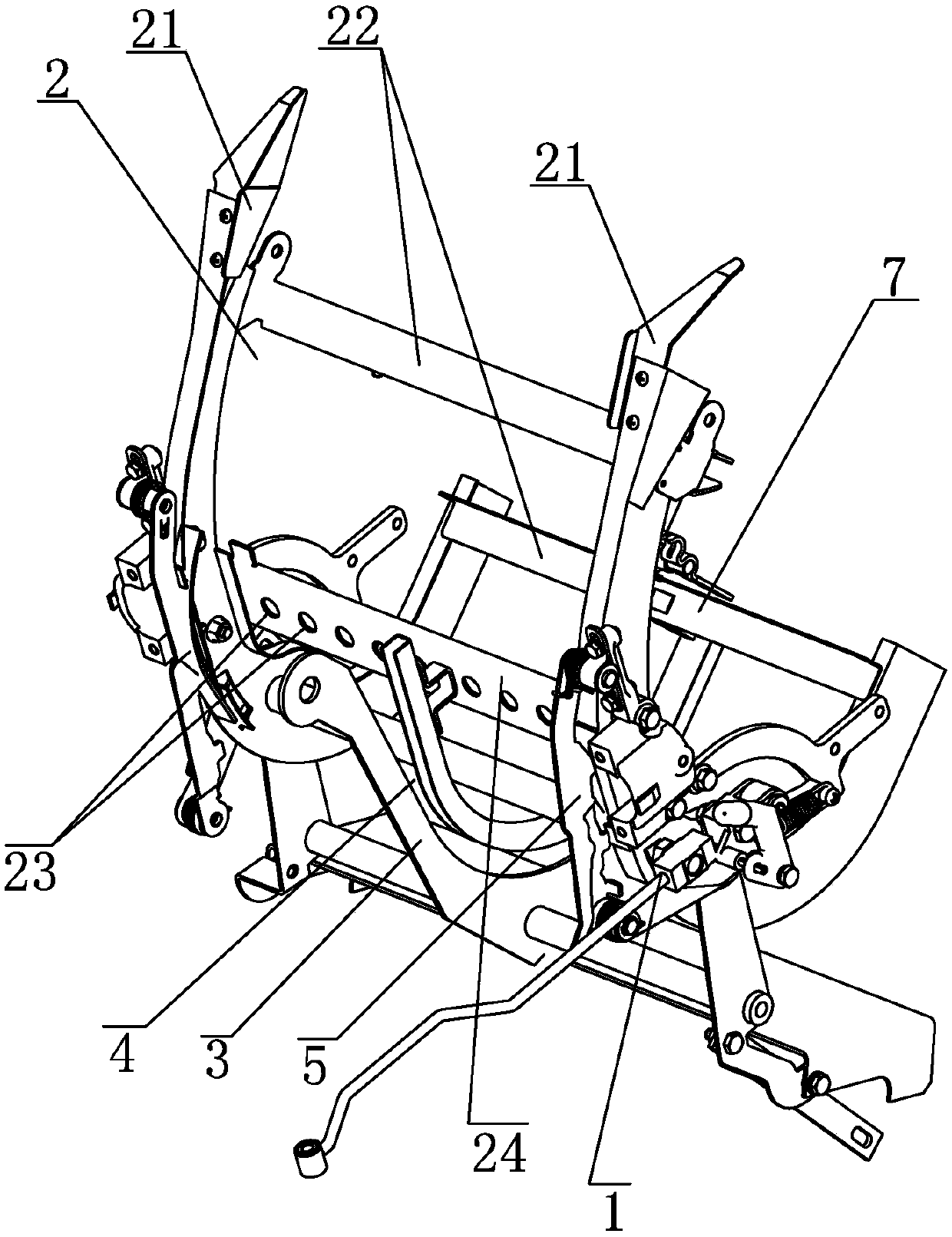

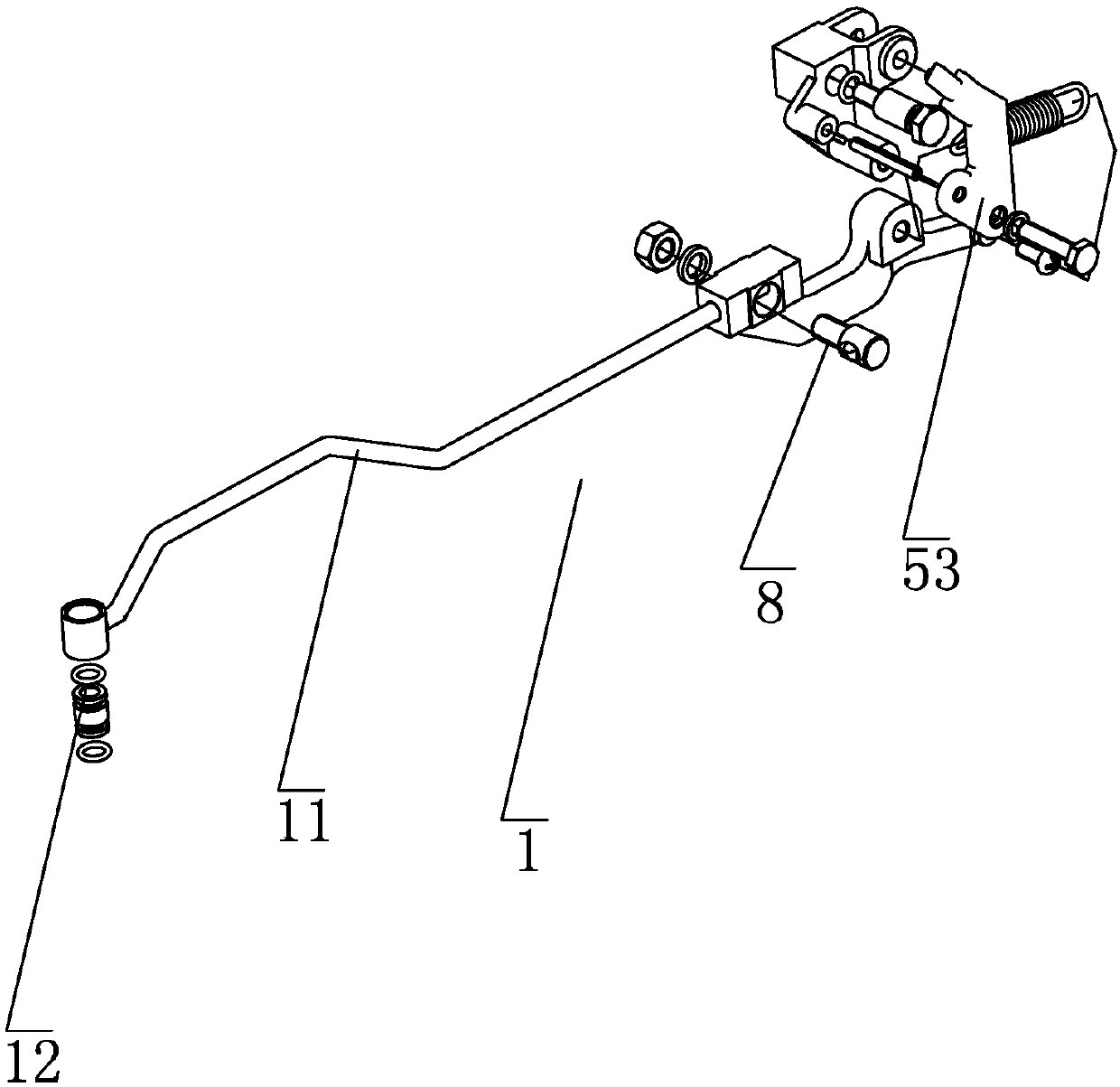

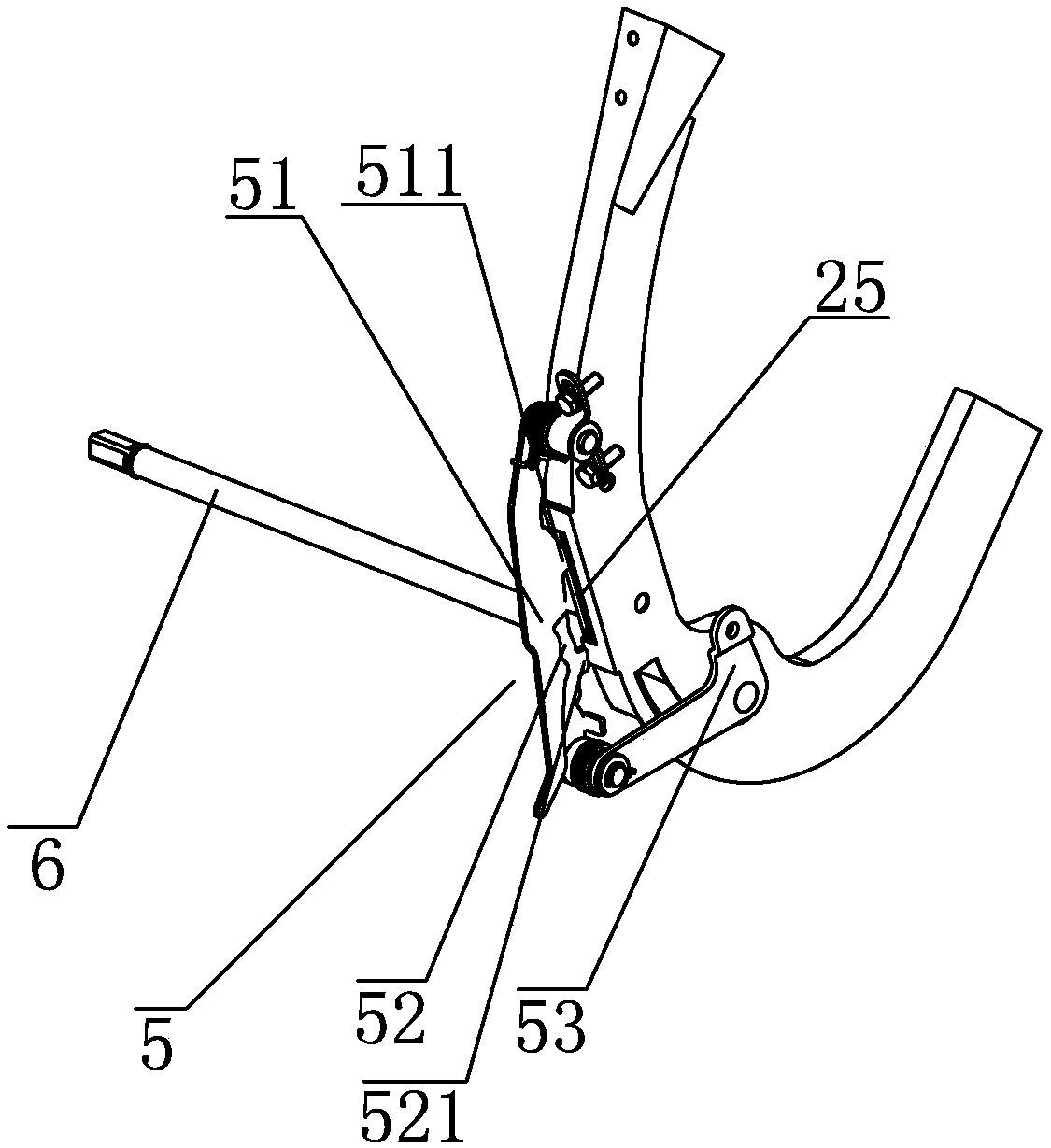

[0014] Embodiment one: see Figure 1-3 As shown, a seedling tray conveying mechanism applied to a green onion transplanting machine includes a seedling tray upper conveying frame 2 and a seedling tray lower conveying frame 3 that are mutually matched and connected through a pull rod assembly 1 and forms a seedling tray passing through a track 4; The conveying frame 2 on the seedling tray is provided with a connecting rod assembly 5 near the side of the pull rod assembly 1. The connecting rod assembly 5 includes an upper connecting rod 51 that is movably installed on the conveying frame 2 on the seedling tray, and moves synchronously with the pull rod assembly 1 through the transmission rod 53. The lower connecting rod 52, the upper connecting rod 51 and the lower connecting rod 52 are connected with each other.

[0015] The conveying frame 2 on the seedling tray includes two symmetrically arranged U-shaped vertical frames 21 and several horizontal frames 22; wherein, the sever...

Embodiment 2

[0016] Embodiment two: see Figure 1-3 As shown, a seedling tray conveying mechanism applied to a green onion transplanting machine includes a seedling tray upper conveying frame 2 and a seedling tray lower conveying frame 3 that are mutually matched and connected through a pull rod assembly 1 and forms a seedling tray passing through a track 4; The conveying frame 2 on the seedling tray is provided with a connecting rod assembly 5 near the side of the pull rod assembly 1. The connecting rod assembly 5 includes an upper connecting rod 51 that is movably installed on the conveying frame 2 on the seedling tray, and moves synchronously with the pull rod assembly 1 through the transmission rod 53. The lower connecting rod 52, the upper connecting rod 51 and the lower connecting rod 52 are connected with each other.

[0017] The lower conveying frame 3 of the seedling tray is located at the bottom of the upper conveying frame 2 of the seedling tray, and the lower conveying frame 3 ...

Embodiment 3

[0018] Embodiment three: see Figure 1-3 As shown, a seedling tray conveying mechanism applied to a green onion transplanting machine includes a seedling tray upper conveying frame 2 and a seedling tray lower conveying frame 3 that are mutually matched and connected through a pull rod assembly 1 and forms a seedling tray passing through a track 4; The conveying frame 2 on the seedling tray is provided with a connecting rod assembly 5 near the side of the pull rod assembly 1. The connecting rod assembly 5 includes an upper connecting rod 51 that is movably installed on the conveying frame 2 on the seedling tray, and moves synchronously with the pull rod assembly 1 through the transmission rod 53. The lower connecting rod 52, the upper connecting rod 51 and the lower connecting rod 52 are connected with each other. The seedling dish that is positioned at the conveying rack 3 under the seedling dish is provided with an automatic neutral gear 7 at the exit of the track 4 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com