Non-scattering type filling uniformizing structure

A dispersing and consistent technology, which is applied in the field of food processing, can solve the problems that the efficiency and precision cannot meet the requirements of modern production, and the quantitative discharge of fillings cannot be achieved, so as to ensure high density, stable feeding and discharging process, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

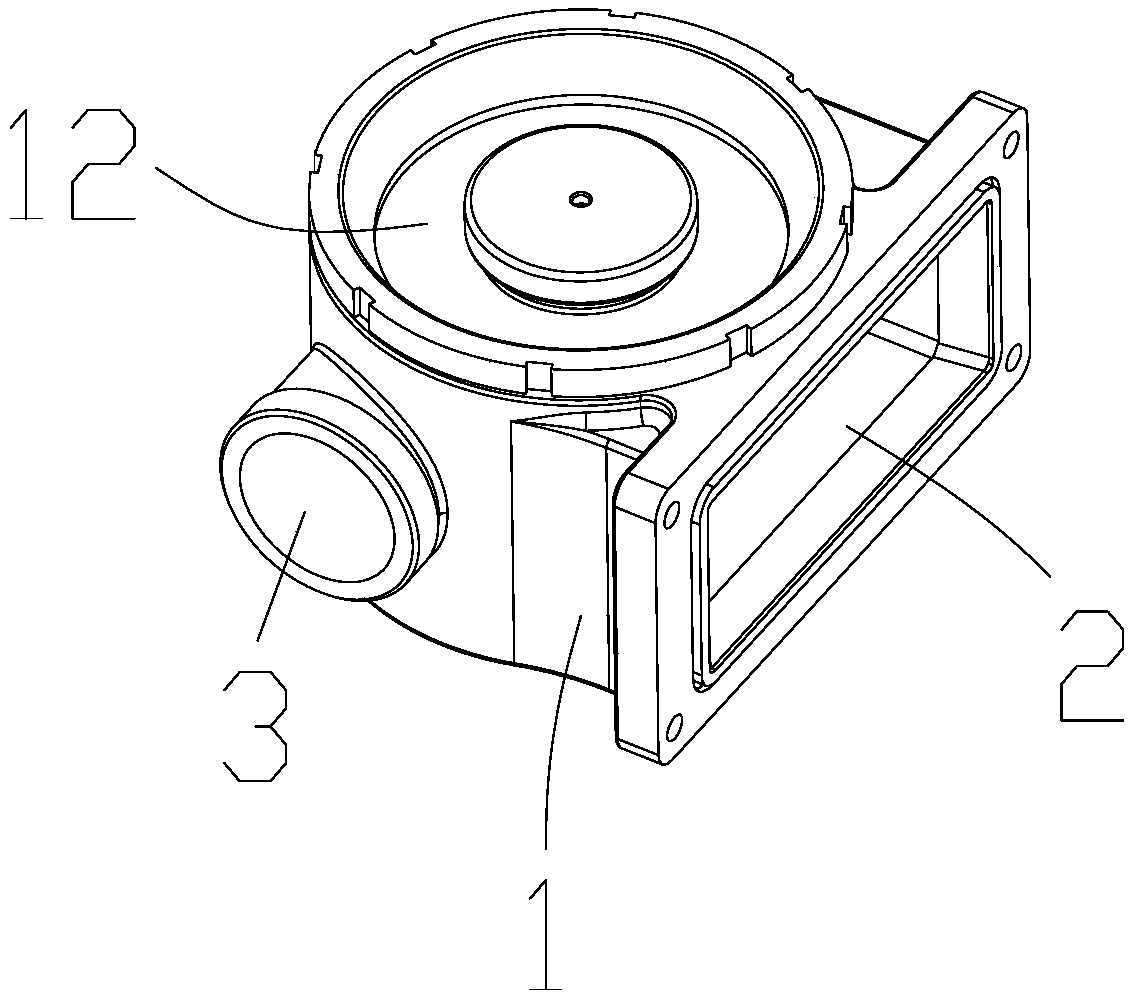

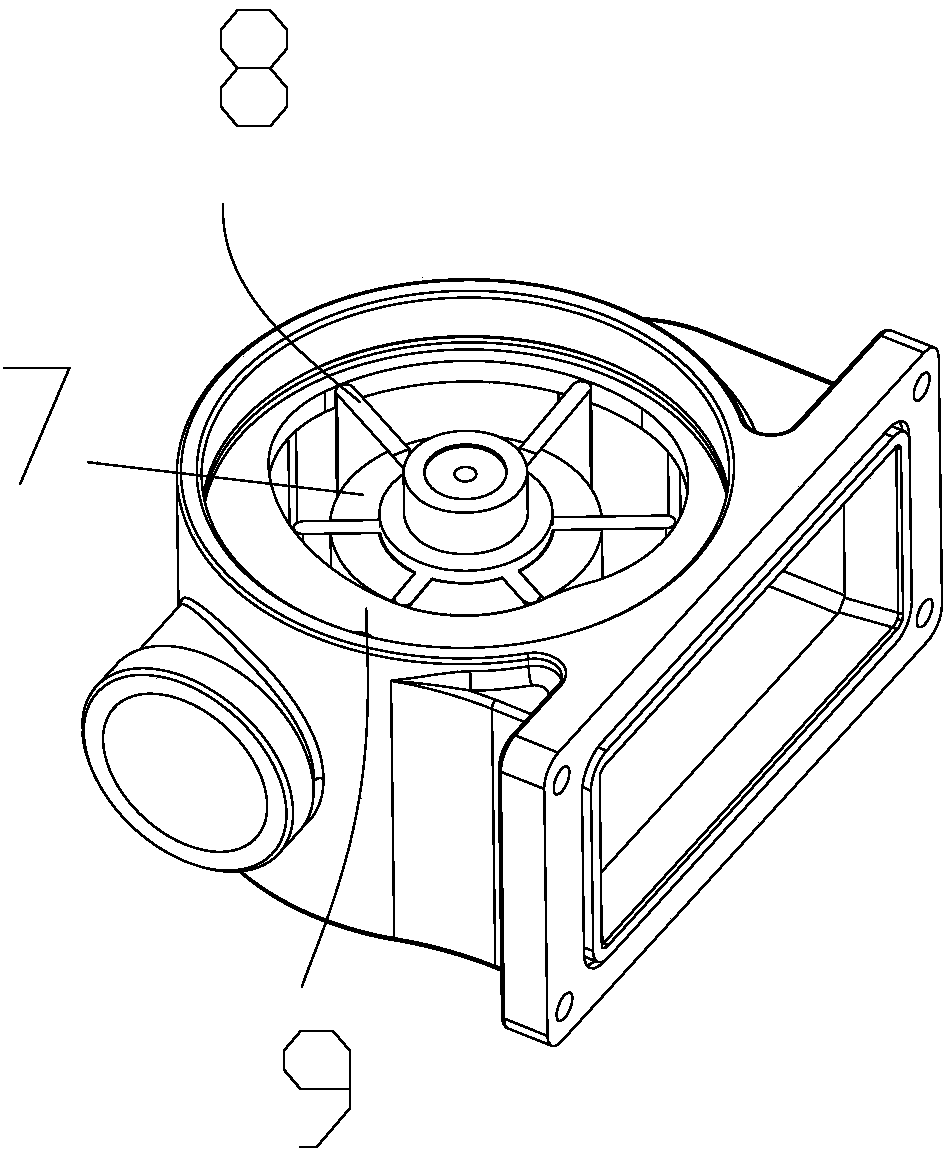

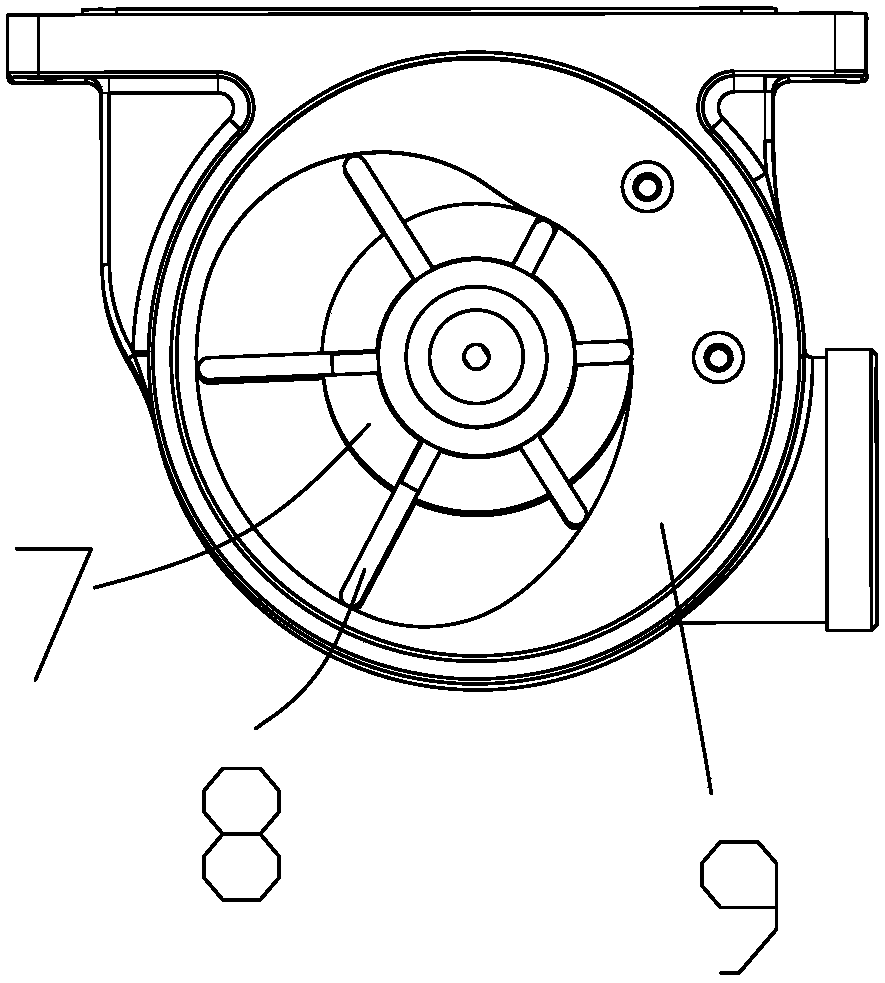

[0043] Such as Figure 1 to Figure 12 As shown, the present embodiment provides a homogeneous material structure, including a housing 1 with an inner cavity, and the housing 1 is provided with an inlet 2 and an outlet 3, and in the inner cavity of the housing 1 A rotating push plate seat 7 is provided, and the feed inlet 2 and the discharge port 3 are located on the peripheral side of the rotation axis of the push plate seat 7;

[0044] The cross-section perpendicular to the axis of the push pedal seat 7 is an arc outer wall, and the push pedal seat 7 is provided with a plurality of push pedals 8 passing through both sides of the push pedal seat 7 and passing through the axis of rotation. The axes are parallel, the push plate 8 and the push plate seat 7 are flexibly connected, and the push plate 8 can reciprocate on both sides of the push plate s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap