Rolling ball manufacturing device adopting vacuum weight loss method and operating method for rolling ball manufacturing device

A manufacturing device and the technology of the weightless method, applied in the field of the vacuum weightless method ball manufacturing device, can solve the problems of complex process, insufficient product flatness and high equipment cost, and achieve the effect of simplifying the manufacturing process, saving the manufacturing cost and reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

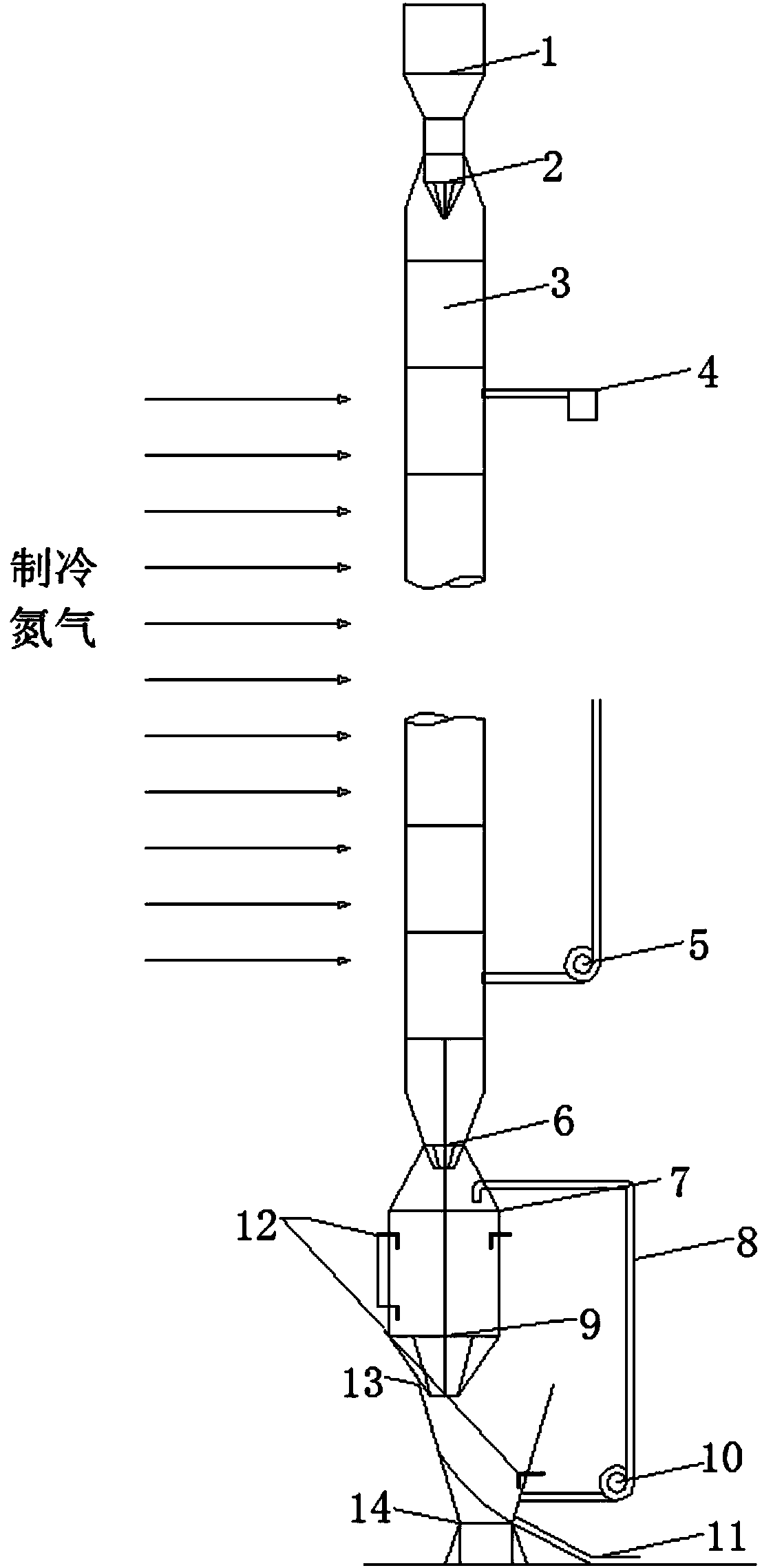

[0022] Such as figure 1 As shown, the vacuum weight loss method ball manufacturing device includes a metal liquid dropper 1, a metal liquid drop inlet 2, a glass condenser 3, a pressure monitor 4, a vacuum pump 5, a forming ball buffer port 6, a buffer liquid cylinder 7, and a return pipe 8. Ball water flow mixing drop port 9, return water pump 10, formed ball chute 11, liquid level gauge 12, buffer solution collection tank 13, bracket 14.

[0023] The metal liquid dripping device 1 and the metal liquid drop inlet 2 are connected by a screw; the metal liquid drop inlet 2 and the glass condenser tube 3 are connected by a rubber seal; each glass condenser tube 3 is connected by a rubber seal; The rubber-tight connection between the glass condenser tube 3 and the pressure monitor 4; the rubber-tight connection ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap