Elastic numerical control milling machine cutter claw

A CNC milling machine and tool claw technology, applied in the field of mechanical processing, can solve the problems of high maintenance cost, large loss, high noise, etc., and achieve the effects of good firmness and stability, reduced noise and wear, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

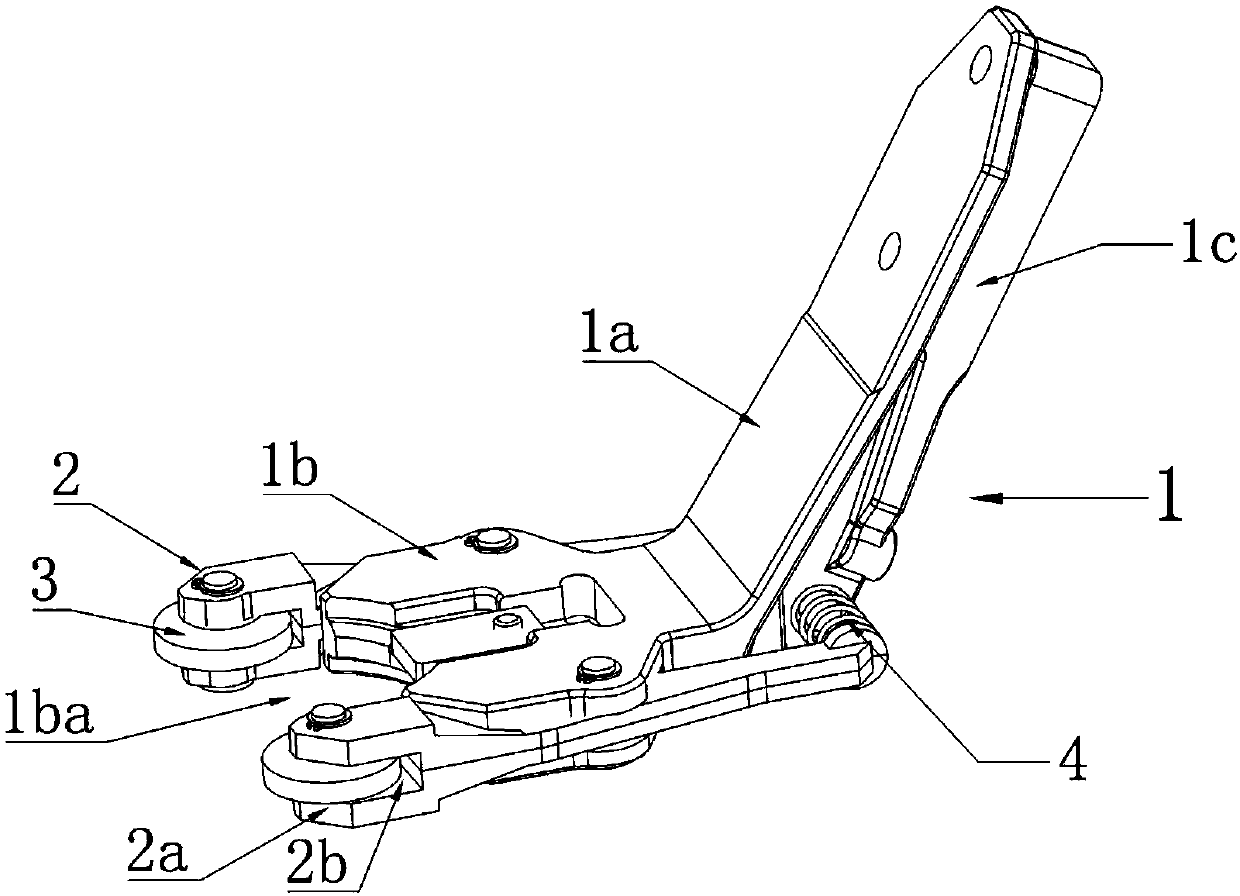

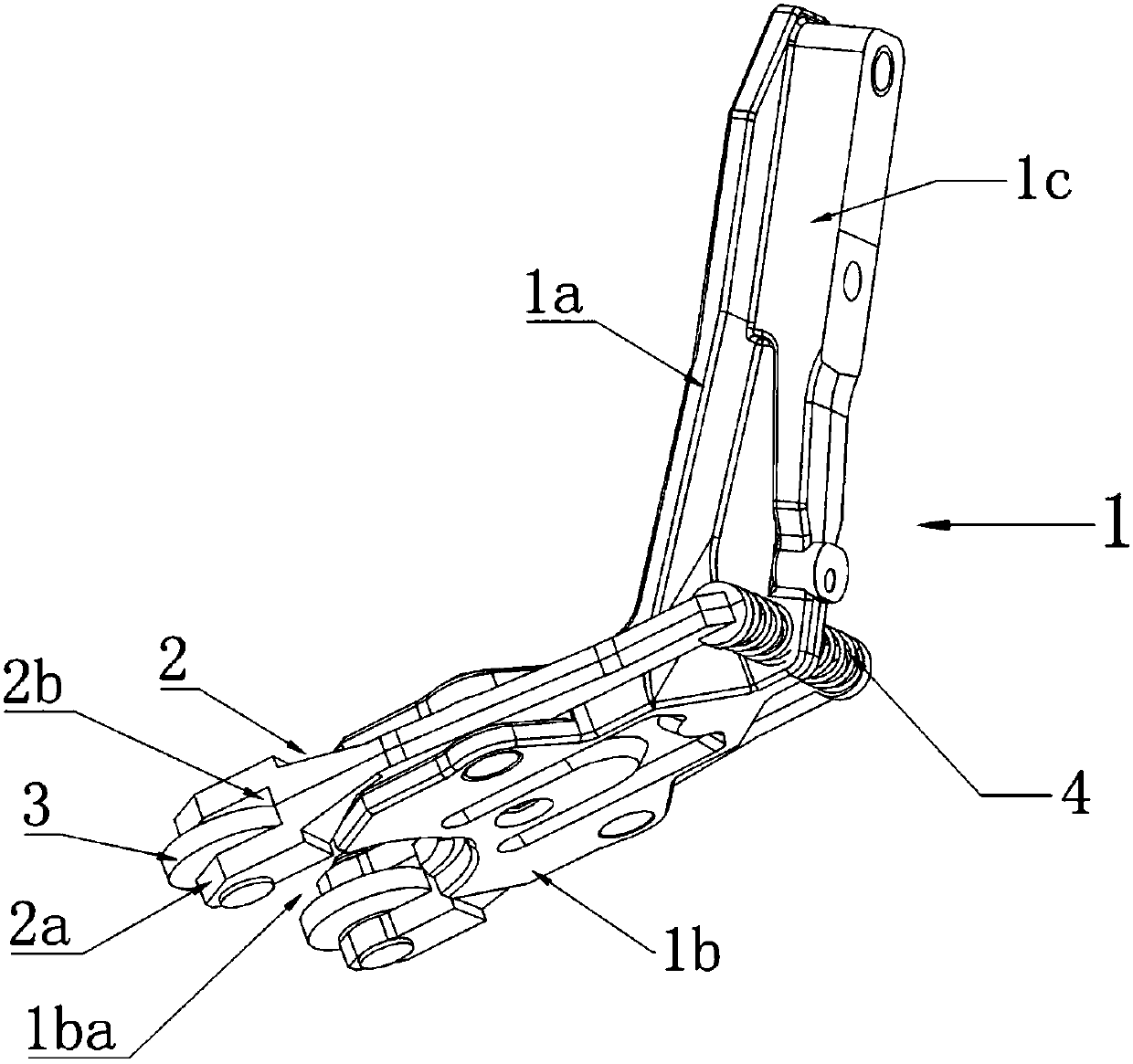

[0014] Such as Figure 1 to Figure 2 A kind of flexible CNC milling machine claw shown has a main body 1, and the main body 1 is bent into a main body part 1a and a setting part 1b, and the gap between the main body part 1a and the setting part 1b The angle range is 110°-125°. The front end of the setting plate part 1b forms a "U"-shaped gap 1ba, and the setting plate part 1b at the left and right ends of the gap 1ba is a two-layer board structure. A foot plate 2 is hingedly embedded between them. A roller 3 is arranged at the front end of the foot plate 2. The plane where the roller 3 is located is parallel to the plane where the setting plate portion 1b is located. The rear end of the foot plate 2 faces backward. Extending to the rear of the main body plate 1a, the rear surface of the main body plate 1a is vertically provided with a rear spine plate 1c, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com