Throat area control device and method in turbine guide vane electric welding process

A turbine guide vane and control device technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of unqualified throat area of turbine blades, welding quality restricted by casting wool, scrapping, etc., and achieve advanced design concepts, The effect of precise device design and low experience requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the drawings.

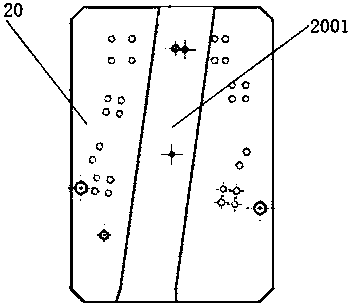

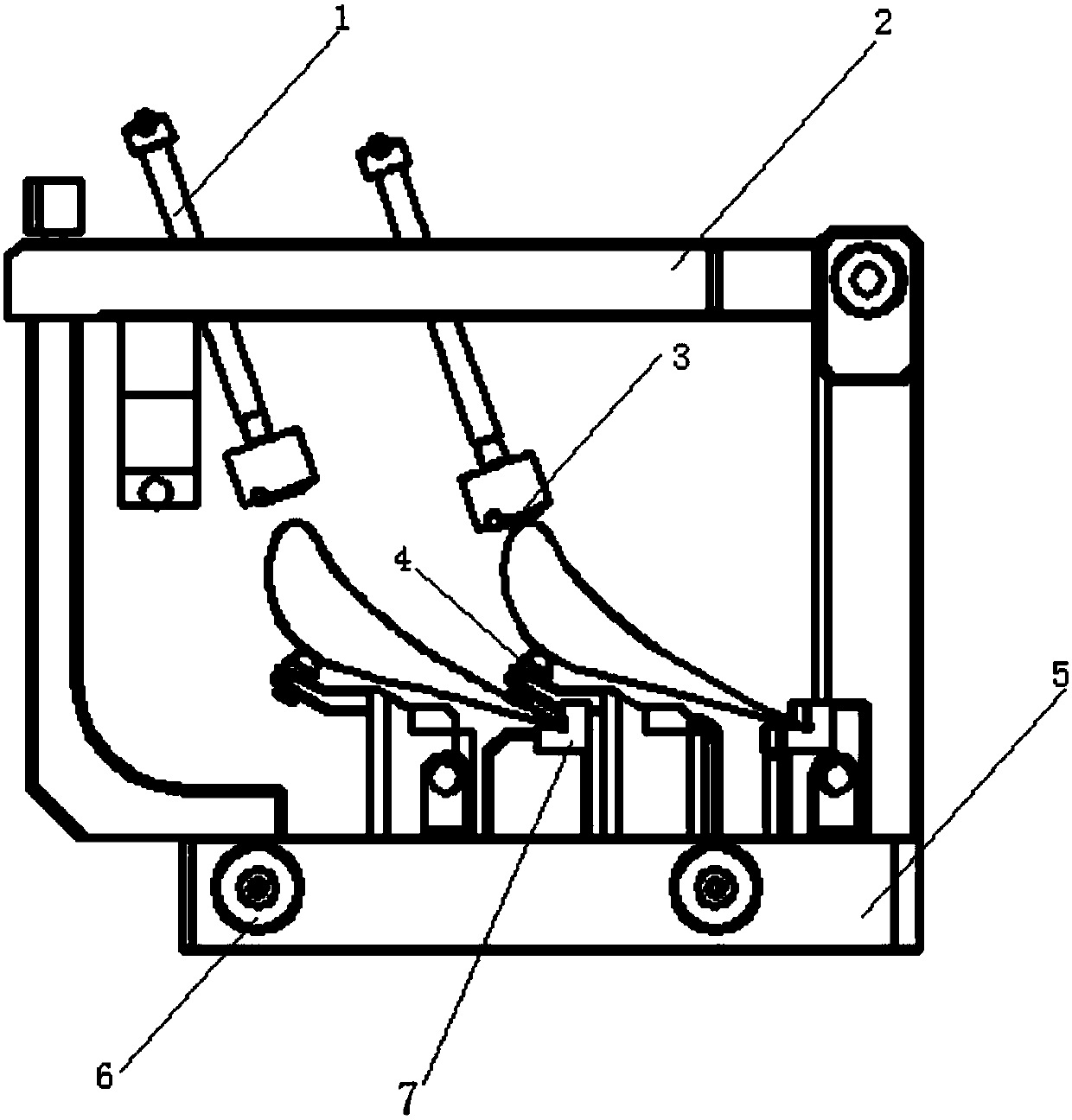

[0046] Such as figure 1 As shown, the present invention provides a throat area control device during spot welding of turbine guide blades, which includes a double-blade positioning fixture, a pre-welding measuring tool, and a welding fixture. Among them, the double-blade positioning fixture serves for quick clamping and The function of disassembling the double blade body; the pre-welding measuring tool is used to fine-tune the blade throat area by matching with the double blade body positioning fixture; the welding fixture is used to weld the adjusted blade body and the edge plate to complete the qualified throat area Turbine blades.

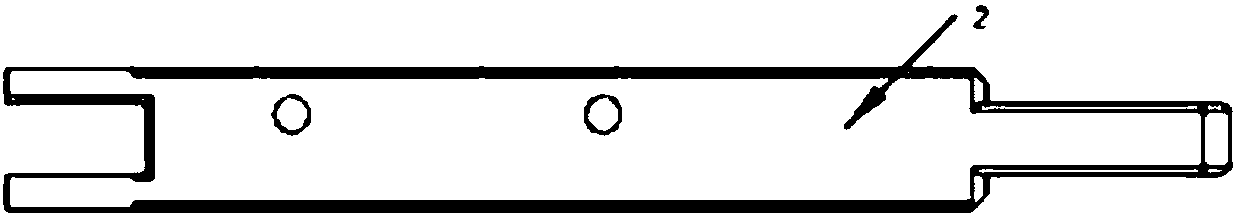

[0047] The double blade positioning fixture includes a compression screw 1, a rotary compression beam 2, a first compression block 3, an area adjustment block 4, a blade positioning and matching base 5, a circular permanent magnet ring 6 and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com