Sliding plate supporting seat

A skateboard and rubber bearing technology, which is applied in the direction of building types, buildings, building components, etc., can solve the problems of limited vertical bearing capacity and large friction coefficient of elastic skateboard devices, and achieve coordinated vertical deformation and small vertical stiffness , to reduce the effect of earthquake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

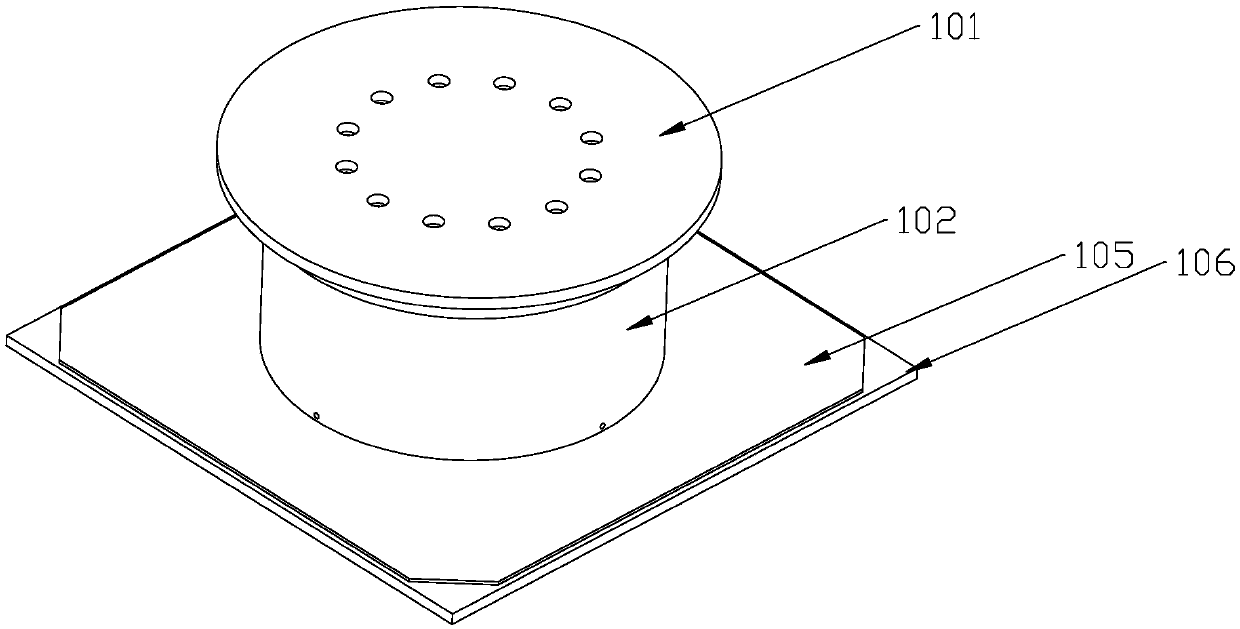

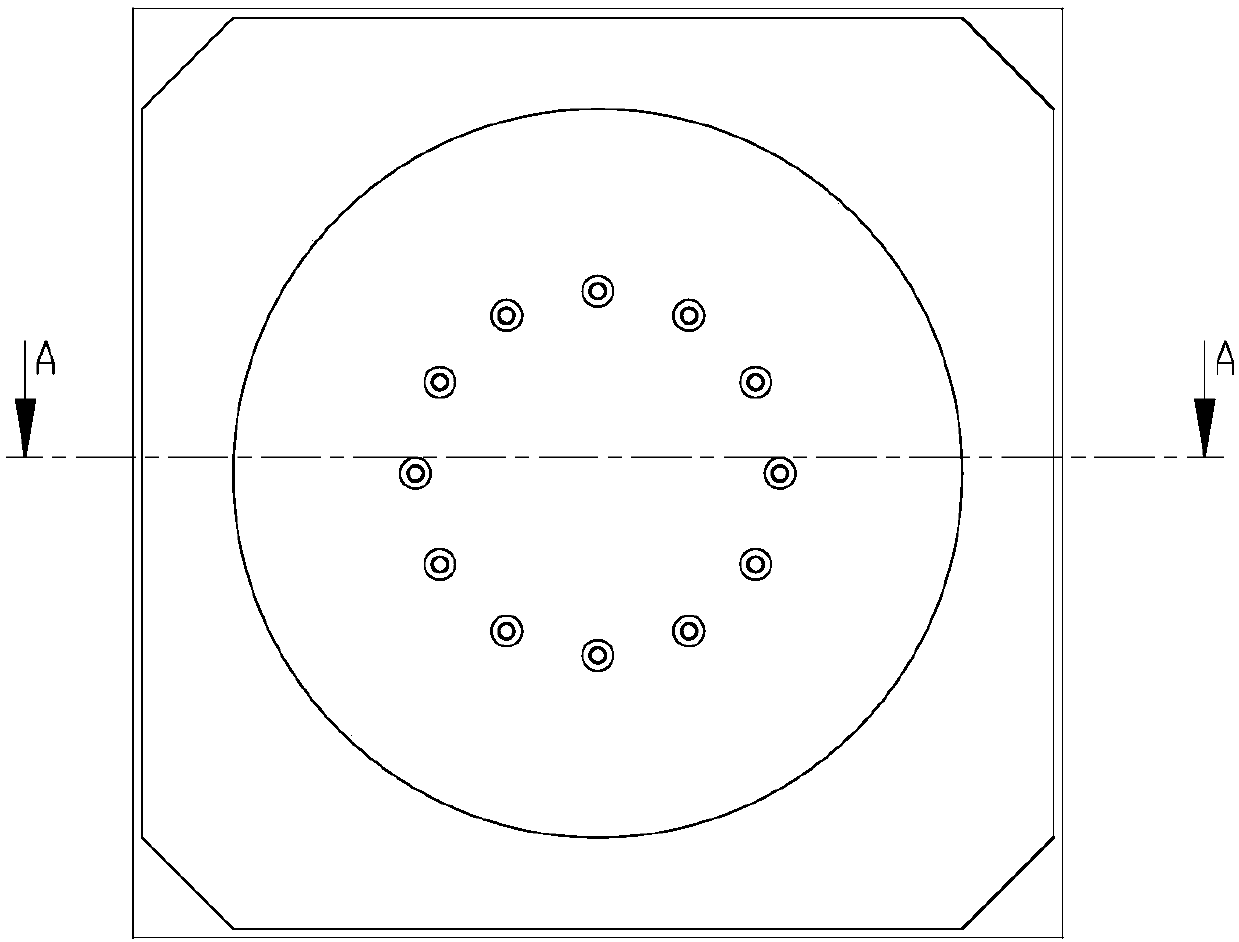

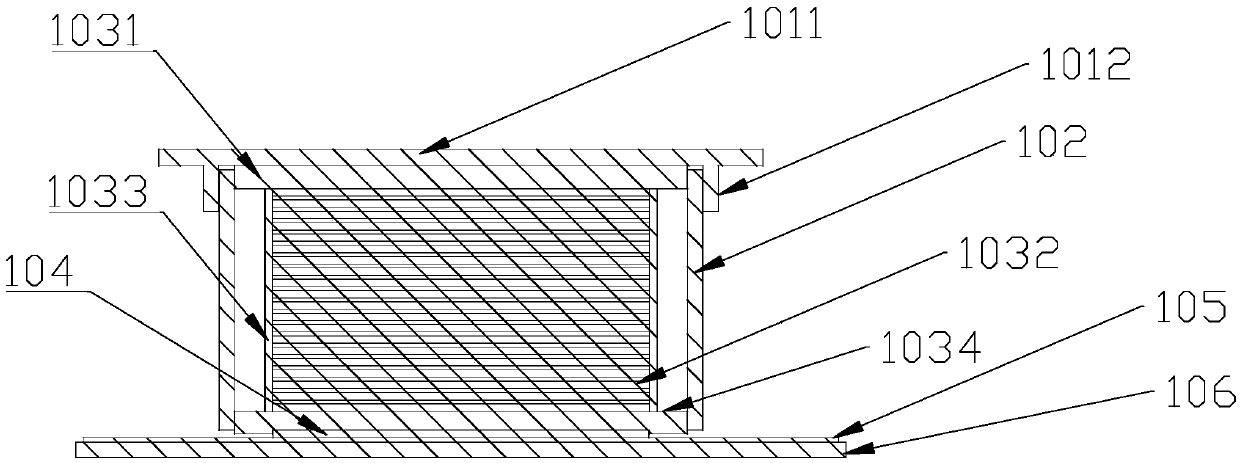

[0031] refer to Figure 1-Figure 4 , this embodiment provides a skateboard support, including an upper connecting plate 101, an outer ring plate 102, a rubber bearing, a polymer material plate 104, a stainless steel mirror plate 105 and a lower connecting plate 106;

[0032] The upper connecting plate 101 includes a connecting plate main body 1011 and a lower ring plate 1012 arranged on the edge of the lower surface of the connecting plate main body 1011, and the upper surface of the connecting plate main body 1011 is used for fixed connection with the upper shock-isolation structure;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com