Device for measuring beat length of polarization maintaining fiber

A polarization-maintaining optical fiber and measurement device technology, which is applied in the direction of measurement devices, optical instrument testing, and machine/structural component testing, can solve problems such as difficult detection of polarization-maintaining performance, save manpower, material resources and time, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

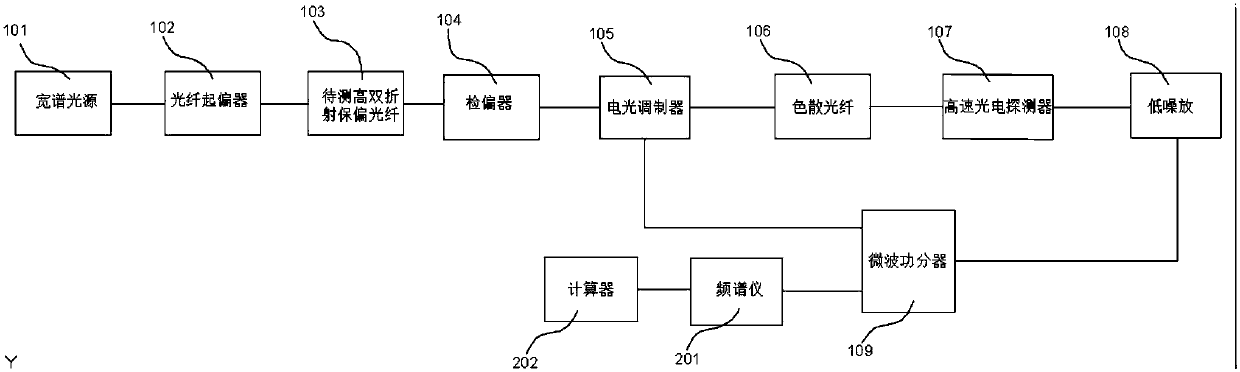

[0019] Example: such as figure 1 As shown, the present invention provides a measurement device for the beat length of polarization-maintaining optical fiber, which is characterized in that it includes a wide-spectrum light source 101, an optical fiber polarizer 102, a spectrum analyzer 201, and a computer 202; the wide-spectrum light source 101 passes through the optical fiber polarizer 102 Enter the high birefringence polarization-maintaining fiber 103 to be tested, and the signal output end of the high-birefringence polarization-maintaining fiber 103 to be tested is connected to a polarization analyzer 104, and the high birefringence polarization-maintaining fiber 103 to be tested and the polarization analyzer 104 together form a Mach Zeng Germany interferometer, Mach-Zehnder interferometer signal output end has electro-optic modulator 105, the light-borne microwave signal on the electro-optic modulator 105 is incident on the high-speed photodetector 107 after passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com