Real-time sampling device for methane detection in the drainage outlet of coalbed methane development process

A technology for coalbed methane development and methane detection, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that it is difficult to guarantee the reliability, accuracy and real-time performance of detection results, and achieve small measurement errors, simple device structure, The effect of rapid gas-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

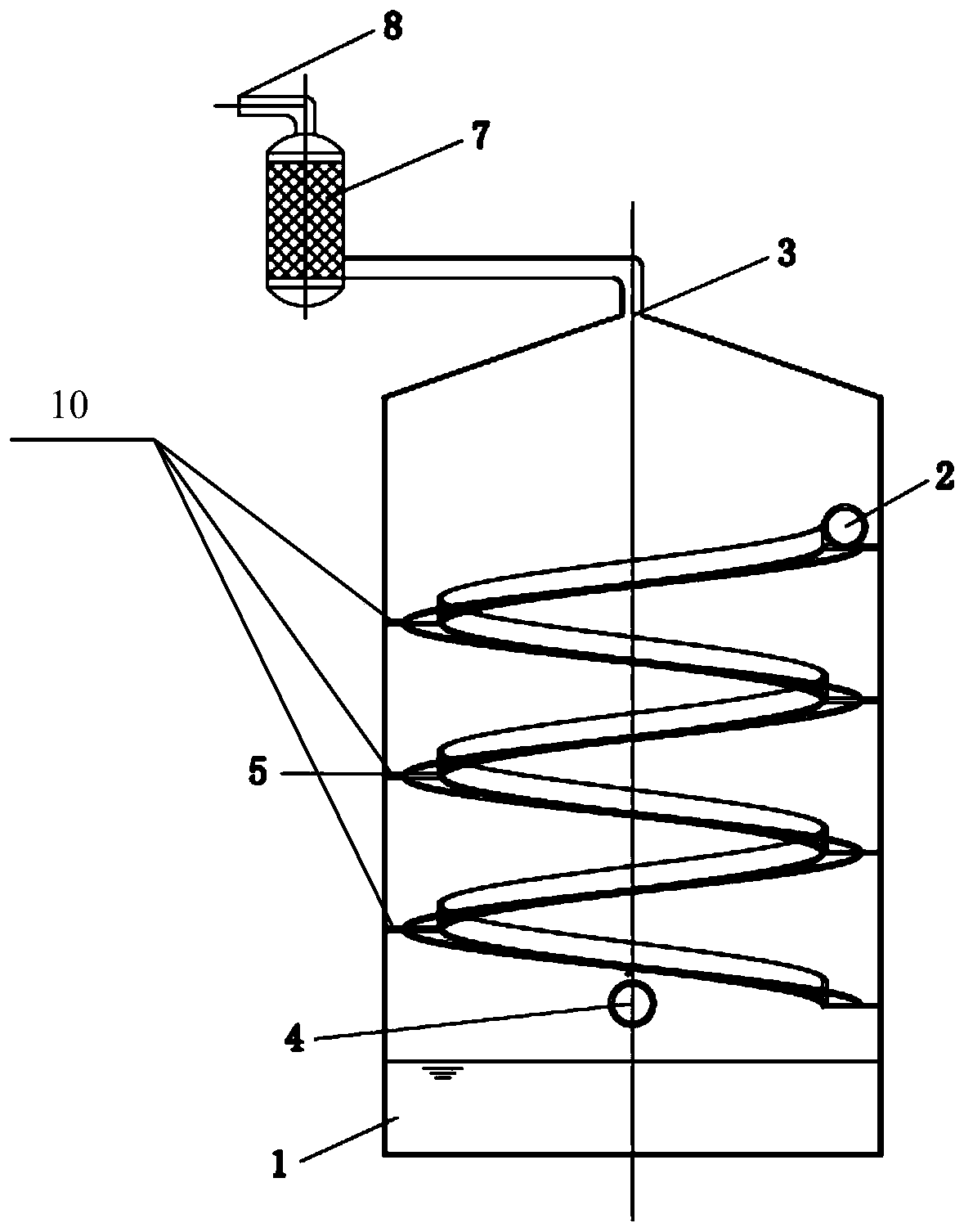

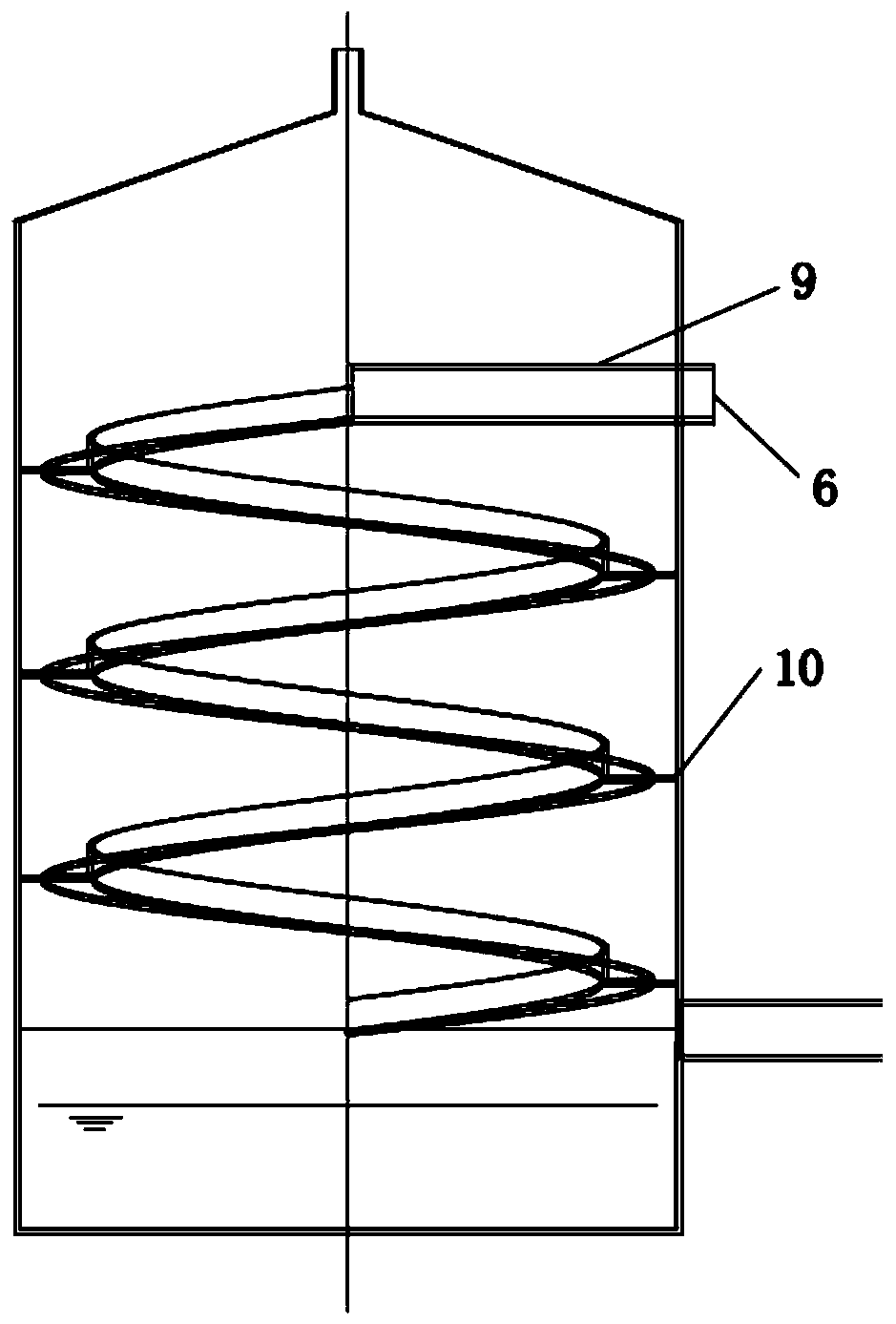

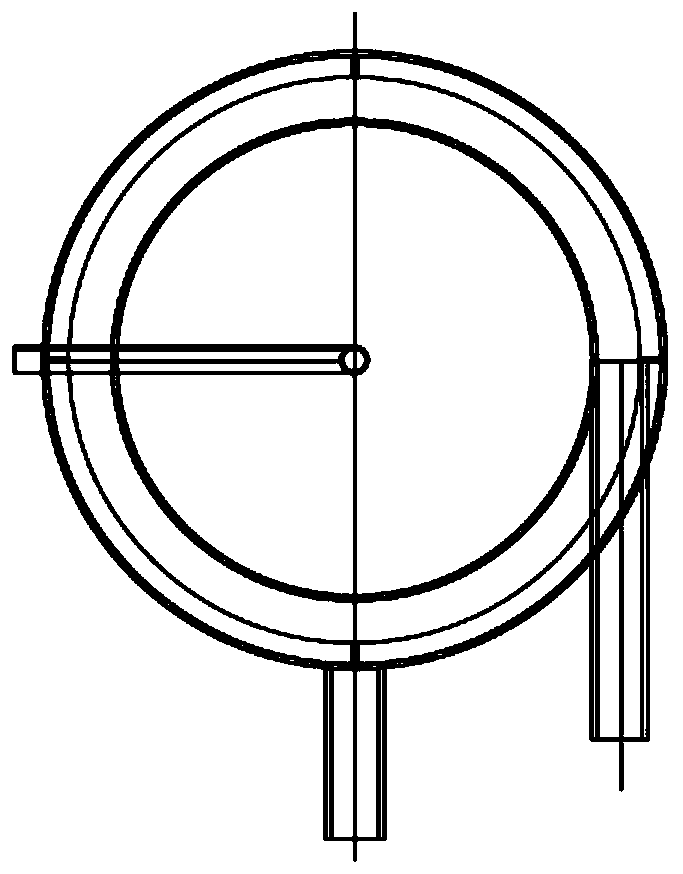

[0030] see figure 1 , figure 2 and image 3 , which are respectively the front view, side view (upper right) and top view of the methane detection device provided in this embodiment. The methane detection device includes a cylindrical water tank 1 with a horizontal bottom and a conical top connected to the cylindrical body; There is a water inlet 2, and the lower part of the side wall is provided with a water outlet 4; the inside of the water tank 1 is provided with a spiral downward water channel 5, one side of the water channel 5 is close to the inner wall, and is connected with the inner wall in a dot shape, and the connection is as shown in the figure 10 As shown, there is a gap for water to flow downward between the non-point connection on this side and the inner wall. The other side of the waterway 5 is provided with a water barrier to prevent water from flowing out from this side. The beginning of the waterway passes through the short pipe 9 It is communicated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com