Airplane oil monitoring device

An oil monitoring and aircraft technology, applied in the field of aircraft oil monitoring devices, can solve the problems of difficulty in analysis and implementation, the influence of the normal operation of the oil system, and the small influence of the flow state of the machine oil, etc., and achieves a simple system structure, good reliability. Scalable and responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

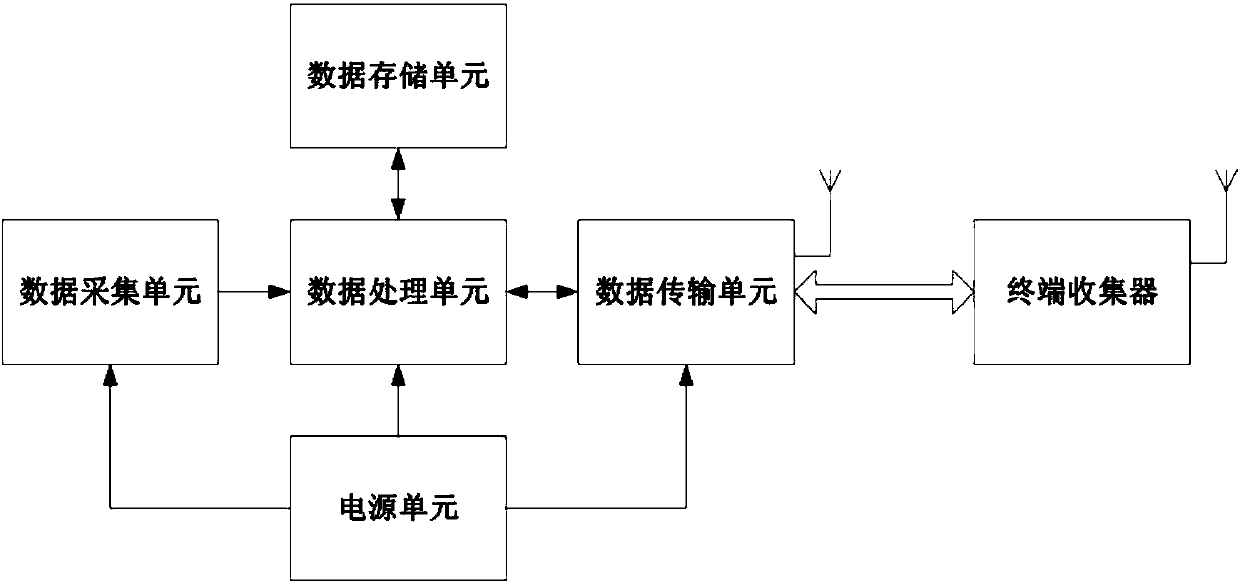

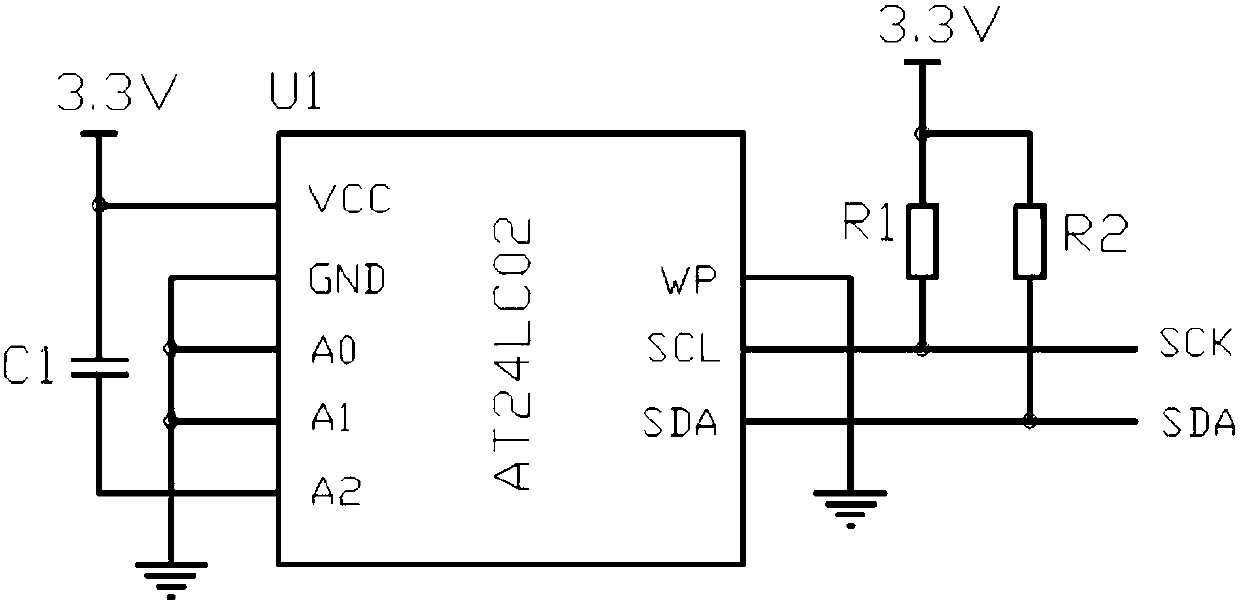

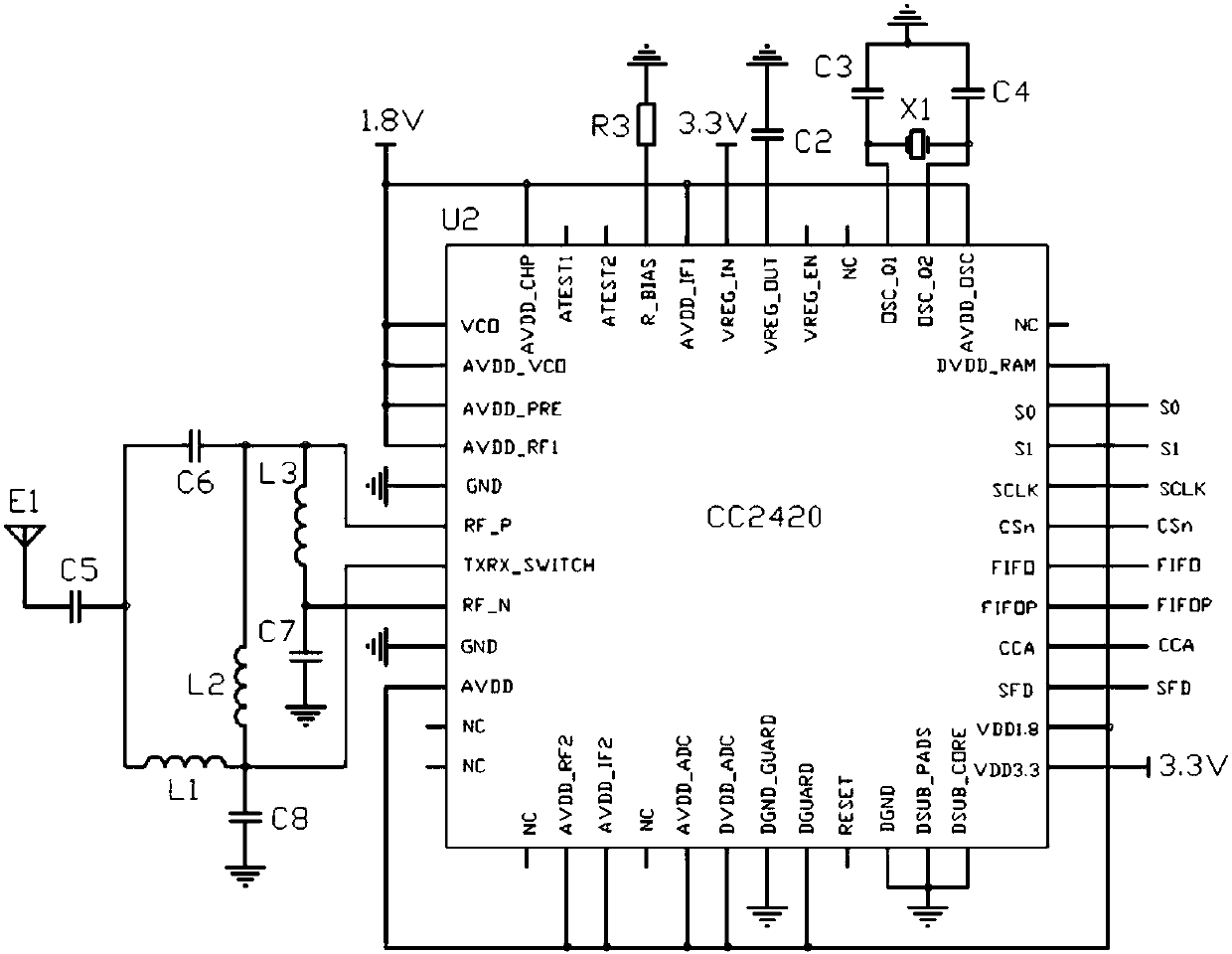

[0019] like figure 1 As shown, an aircraft oil monitoring device is installed on the oil circuit of important parts such as the engine, landing gear, flaperon or empennage of the aircraft; the device includes a data acquisition unit, a data processing unit, a data storage unit, and a data transmission unit and power supply unit; the data acquisition unit uses an embedded oil analysis sensor to monitor the lubricating oil condition of the lubricating oil pipeline in the engine compartment or the hydraulic oil condition of the hydraulic oil pipeline of the landing gear, flaperon, and empennage, and output analog voltage signals to send into the A / D conversion channel of the data processing unit; the data processing unit processes the data collected by the data acquisition unit, and the output is respectively connected to the data sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com