A kind of CO base catalyst and its preparation method and the application in the conversion of eugenol

A catalyst, eugenol technology, applied in the preparation of Co-based catalysts, the application field of eugenol conversion, to achieve high activity, improved stability, and selectivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

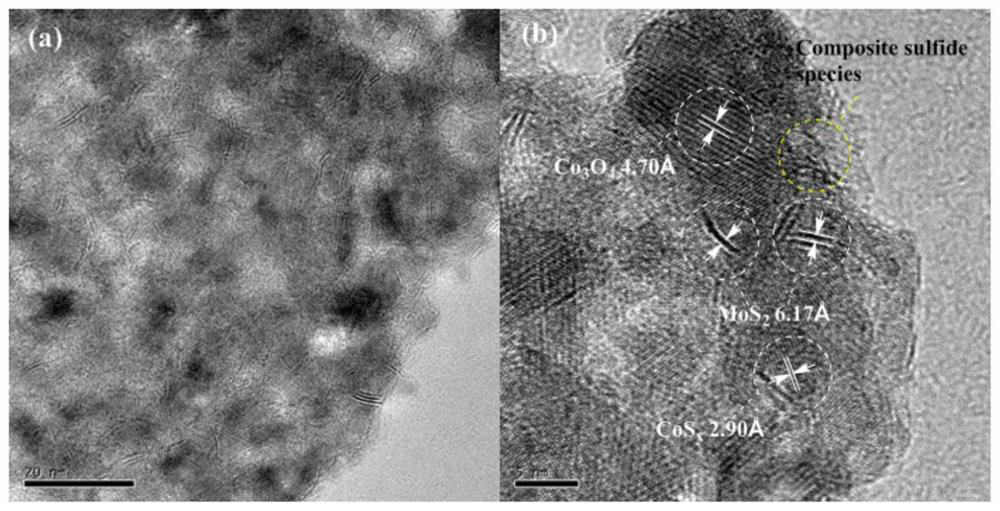

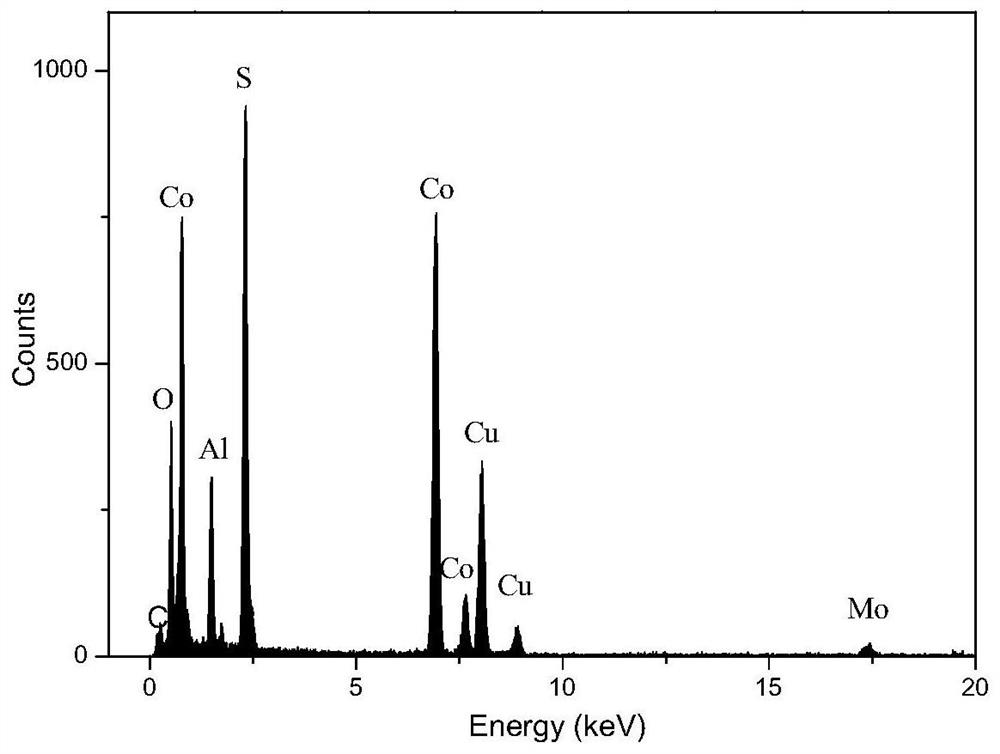

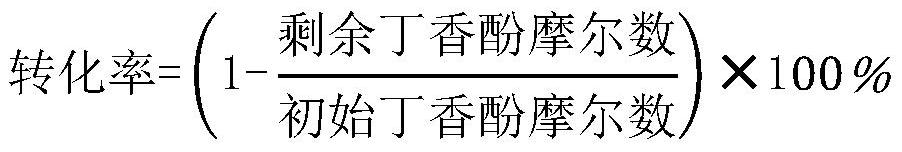

Method used

Image

Examples

Embodiment 1

[0032] This embodiment illustrates the preparation of CoAl hydrotalcite of Co:Al=5:1 in the present invention

[0033] Weigh 0.1mol of cobalt nitrate and 0.02mol of aluminum nitrate and dissolve in 250ml of deionized water, stir until clear; weigh 9.6g (0.24mol) of sodium hydroxide, and dissolve 6.36g (0.06mol) of sodium carbonate in 250mol of deionized water , stir until clarification; drop the two solutions into 500ml deionized water at the same time, stir in a water bath at room temperature, control the titration rate at 1 drop / second, fine-tune the titration rate according to the pH, and ensure that the pH=9-10; after the titration , stop stirring, keep for 40min, and then transfer to an oven, the temperature is set at 70°C, and the crystallization time is set at 12h. After the crystallization, the precipitate was filtered and washed with deionized water until the pH was neutral, and the obtained precipitate was dried at 70°C for 12 hours to obtain hydrotalcite with Co:Al=...

Embodiment 2

[0035] This example illustrates the preparation of CoAl hydrotalcite of Co:Al=1:1 in the present invention

[0036] The preparation method is similar to that of Example 1, keeping other conditions unchanged, changing the weighing amounts of cobalt nitrate and aluminum nitrate to 0.06 mol and 0.06 mol, respectively, to obtain hydrotalcite with Co:Al=1:1.

Embodiment 3

[0038] This example illustrates the preparation of CoAl hydrotalcite of Co:Al=1:5 in the present invention

[0039] The preparation method is similar to that of Example 1, keeping other conditions unchanged, changing the weighted amounts of cobalt nitrate and aluminum nitrate to 0.02 mol and 0.1 mol, respectively, to obtain hydrotalcite with Co:Al=1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com