Auxiliary receivers for electrospinning machines

A technology of electrospinning machine and receiving device, which is applied in the direction of textiles and papermaking, filament/thread forming, fiber treatment, etc., to achieve the effect of expanding the application range, continuous and stable spinning effect, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the embodiments given in the drawings.

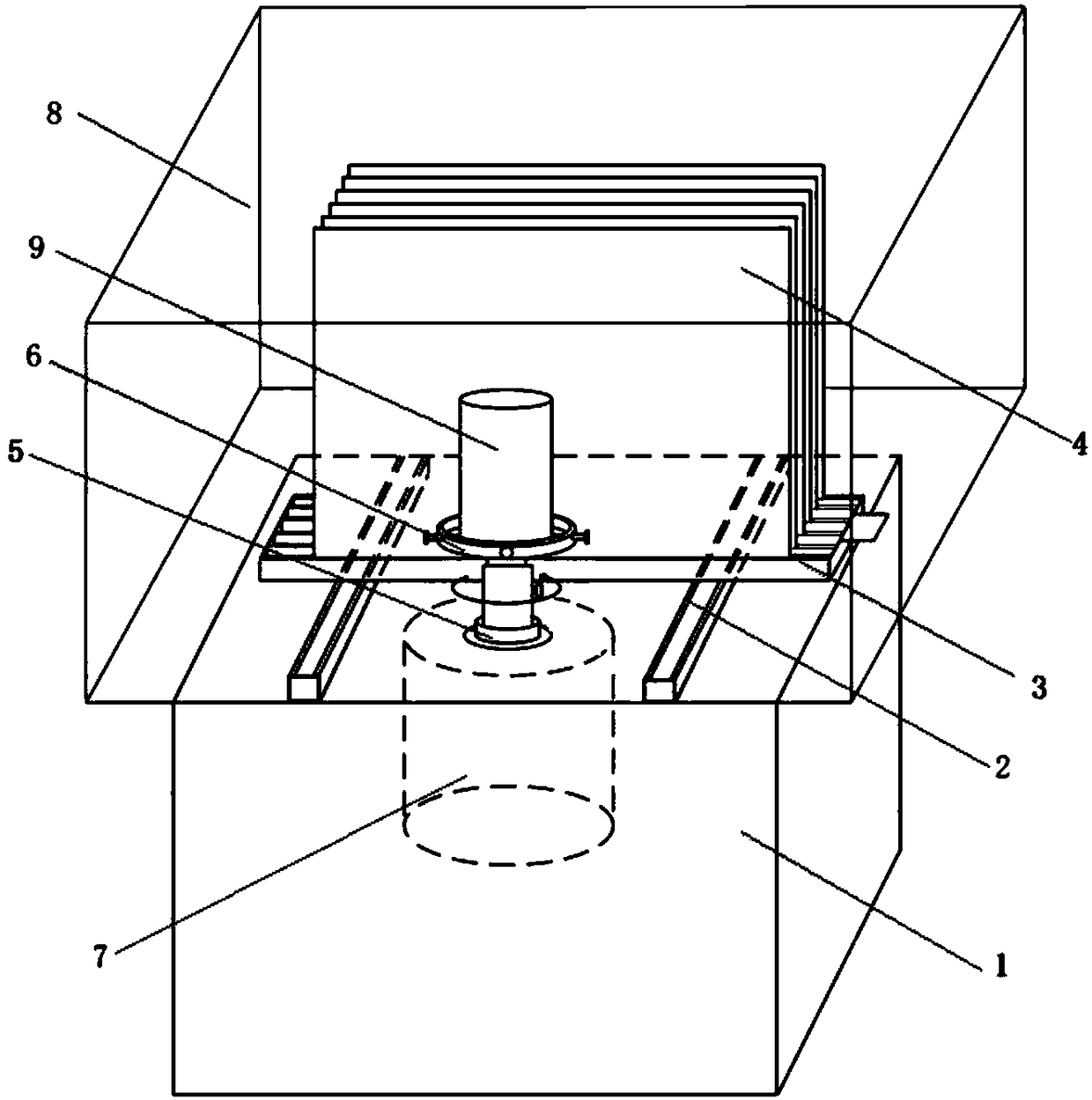

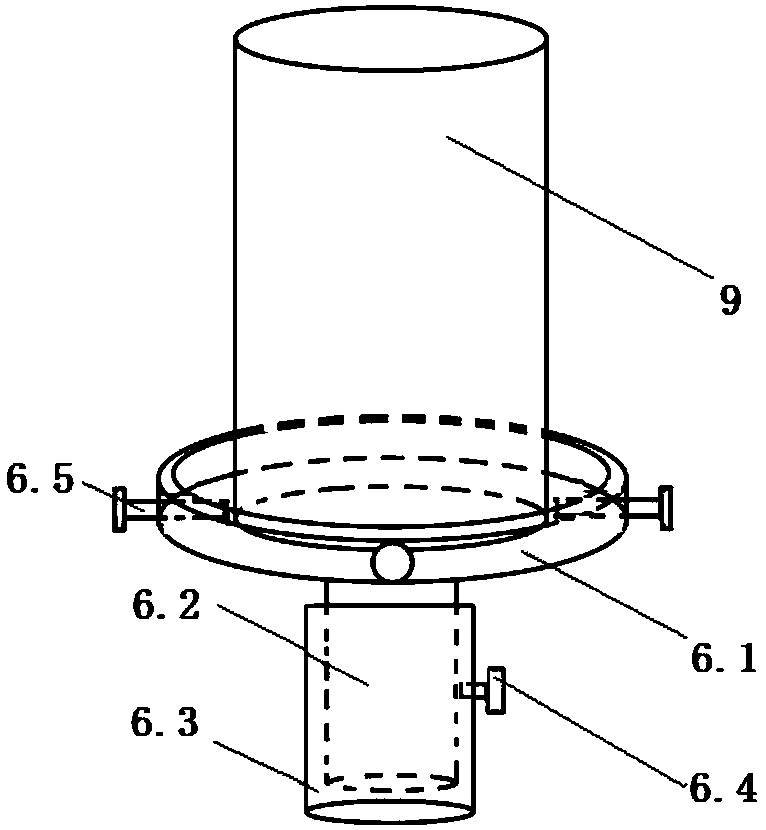

[0024] Reference figure 1 , An auxiliary receiving device for an electrospinning machine, comprising an insulator stand 1, two parallel insulator slide rails fixed on the stand 2, and arranged on the insulator slide rail 2 to move longitudinally along the slide rail The conductor base plate 3, the pole plate 4 inserted on the conductor base plate 3, the plate surface of which is perpendicular to the direction of movement of the conductor base plate 3, and the rotating table set on the insulator stand 1 on the side corresponding to the center line of the pole plate 4 5 and a height-adjustable sample loading table 6 arranged on the center of the rotating table; the rotating table 5 is drivingly connected with the motor 7 arranged in the insulator stage 1; one end of the conductor seat plate 3 is connected to the static The negative pole of the high-volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com