Bus electrode framework, thermosensitive printing head and preparation method of thermosensitive printing head

A thermal print head and bus electrode technology, applied in printing and other directions, can solve the problems of increasing the volume of the thermal print head and unfavorable miniaturization of the thermal print head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

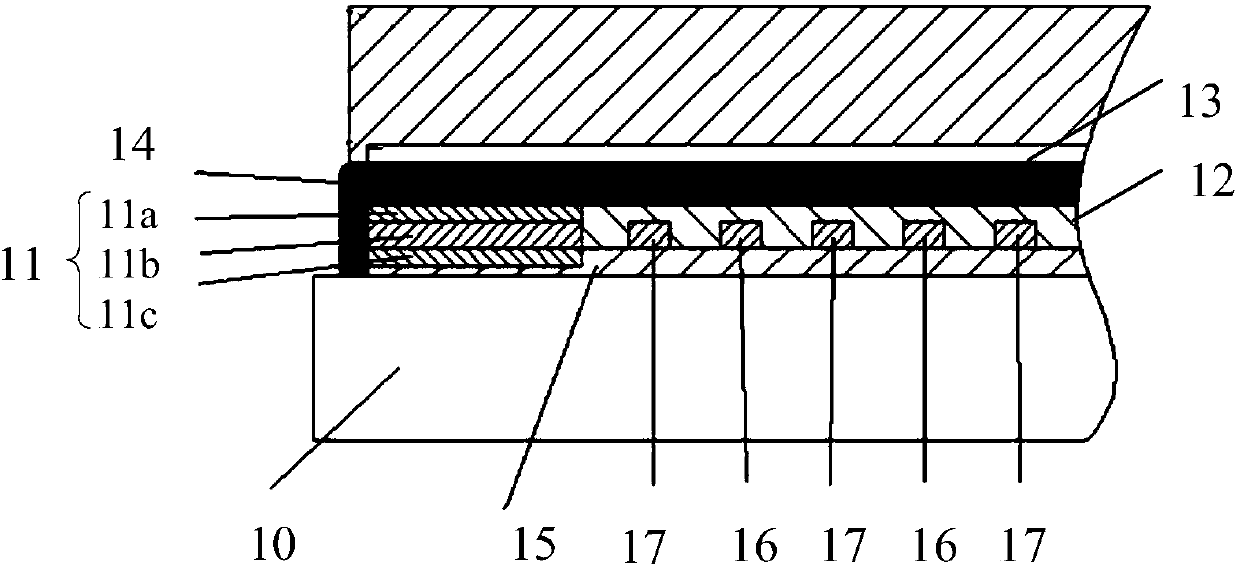

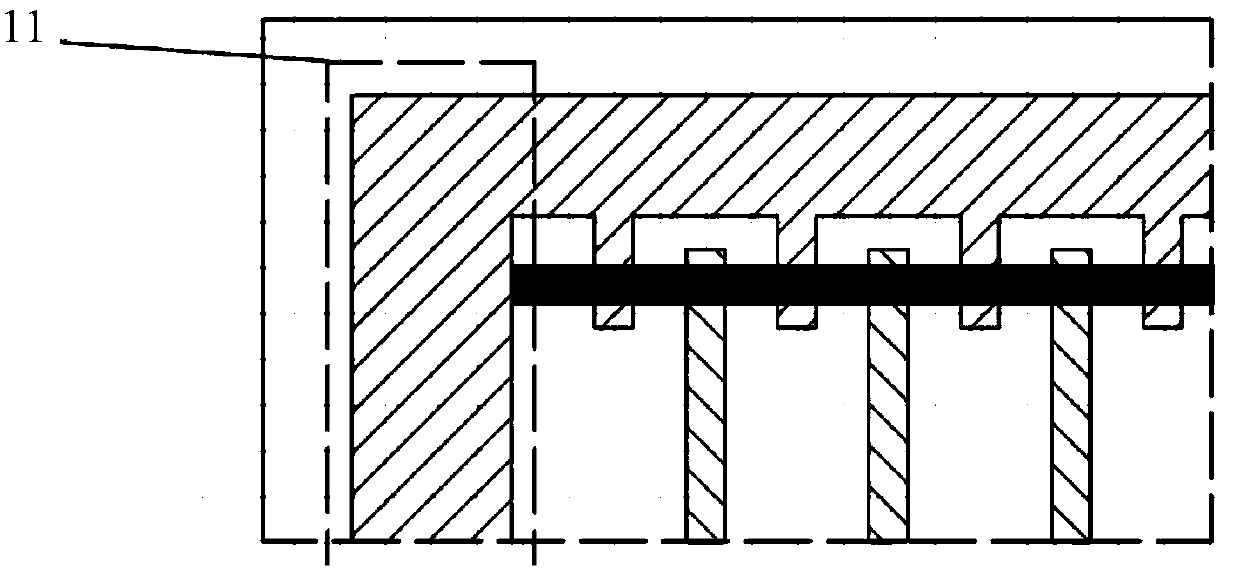

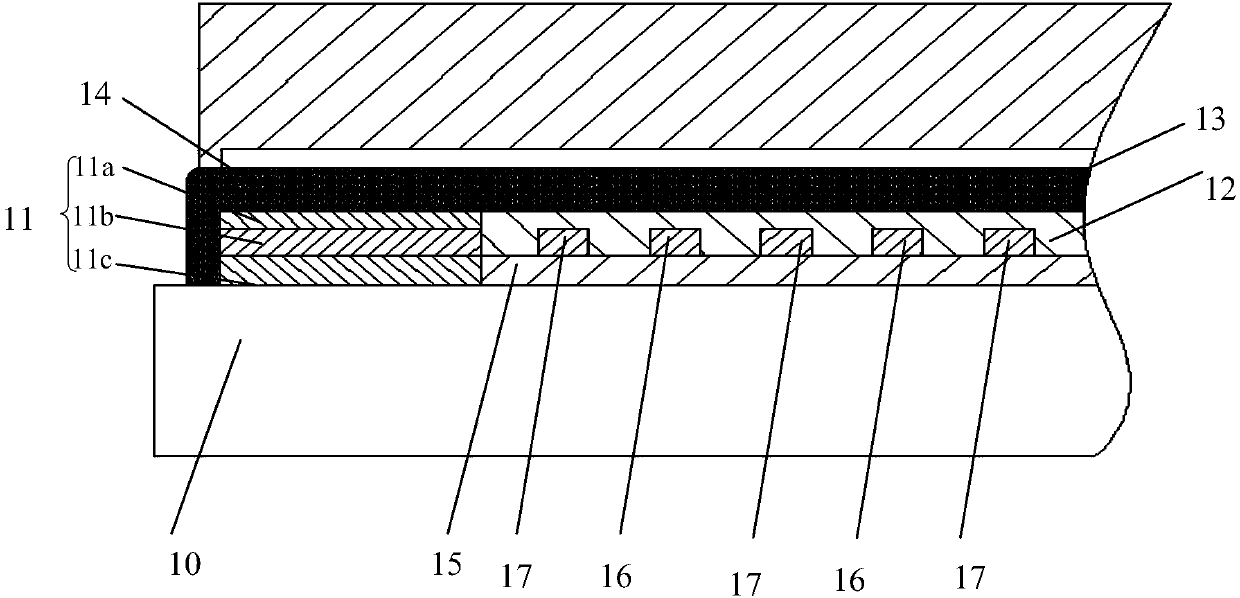

Image

Examples

preparation example Construction

[0055] The invention also provides a preparation method of the thermal printing head.

[0056] see Image 6 , the preparation method of the thermal printing head in an embodiment, comprises the following steps:

[0057] S11: Printing a heating resistor on the substrate to form a heating resistor band.

[0058] Specifically, a heating resistance layer is printed on the substrate to form a heating resistance band. In one embodiment, the common electrodes and the individual electrodes are printed on the substrate first, and then the heating resistors are printed to cover the common electrodes, the individual electrodes and the substrate in the area between the common electrodes and the individual electrodes to form a heating resistor strip.

[0059] S12: Print the bus electrode above the substrate in the lateral direction of the heating resistor, and print the bus electrode from the initial printing surface lower than the heating resistor until the height of the bus electrode r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com