Recyclable oily sewage treatment device

A treatment device and technology for oily sewage, applied in flotation water/sewage treatment, centrifugal separation water/sewage treatment, grease/oily substance/floating matter removal device, etc., can solve the problems of complex structure and high cost, and achieve work efficiency Improve and reduce oil content, and the effect of compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

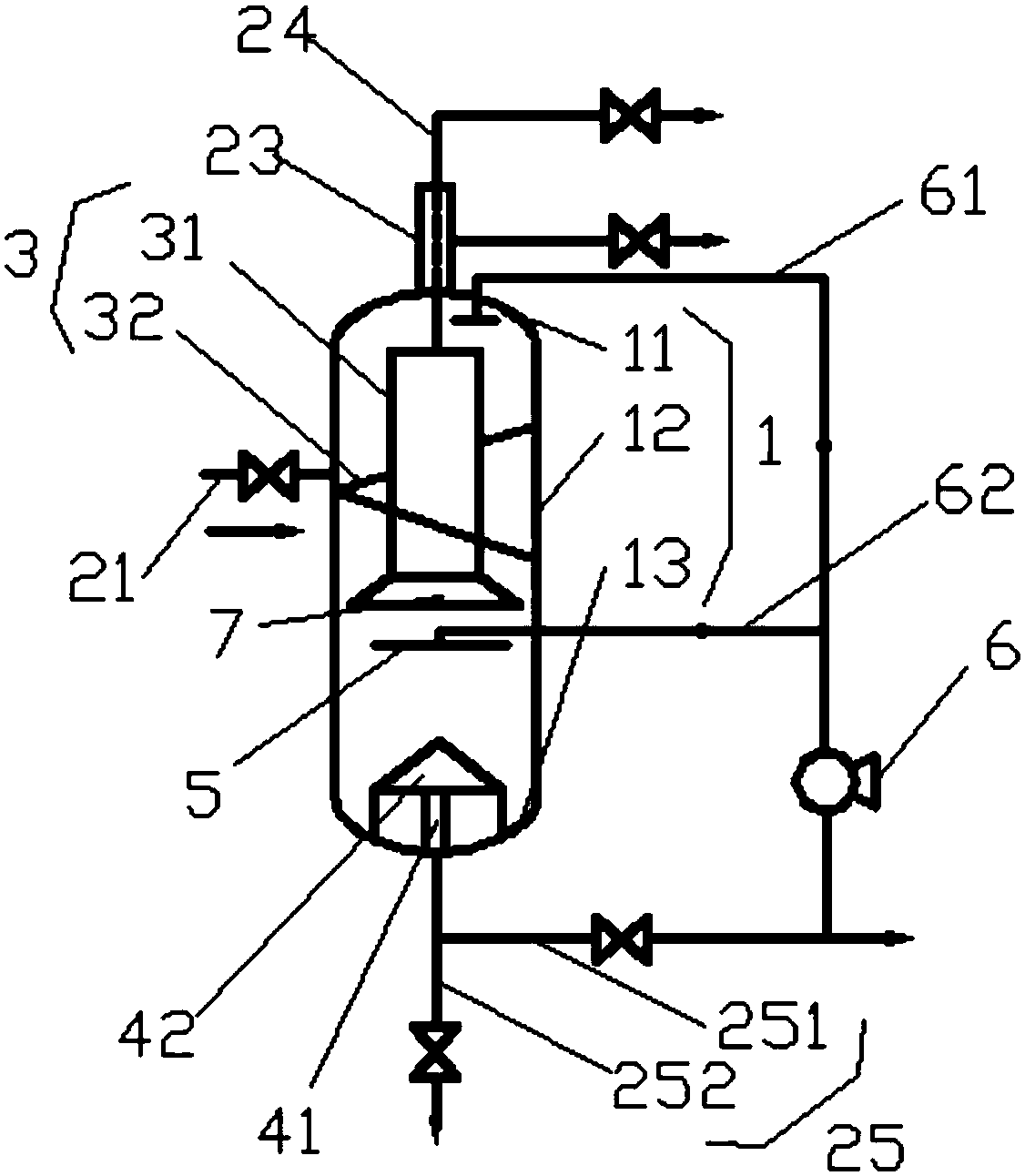

[0031] figure 1 It is a schematic device diagram of a recyclable oily sewage treatment device according to an embodiment of the present invention. Such as figure 1 As shown, the circulating oily sewage treatment device may generally include a shell 1, an inlet and outlet pipeline, a separation device 3 and a circulation loop. The shell 1 is composed of a cylindrical outer cylinder 12 , an upper sealing head 11 and a lower sealing head 13 . The inlet and outlet pipelines are composed of oily sewage inlet pipe 21, primary overflow pipe 23, secondary overflow pipe 24 and outlet pipe 25; wherein, the oily sewage inlet pipe 21 is horizontally connected to the upper half of cylindrical outer cylinder 12, and the primary overflow pipe The flow pipe 23 is located at the center of the upper head 11, the secondary overflow pipe 24 is coaxial with the primary overflow pipe 23 and the pipe diameter is smaller than the primary overflow pipe 23, and the outlet pipe 25 is located at the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com