Flexible composite graphite-based material with high heat conduction property and preparation method thereof

A composite graphite, high thermal conductivity technology, applied in the field of materials, can solve the problems of limited application scope and inability to meet the heat dissipation requirements of high-heating components, and achieve the effect of reducing thermal resistance and widening application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Step 1: Add alumina powder to the liquid acrylic resin in a certain proportion, mix well and put it into a molding mold, the size of the molding mold is determined by the size of the graphite sheet after folding;

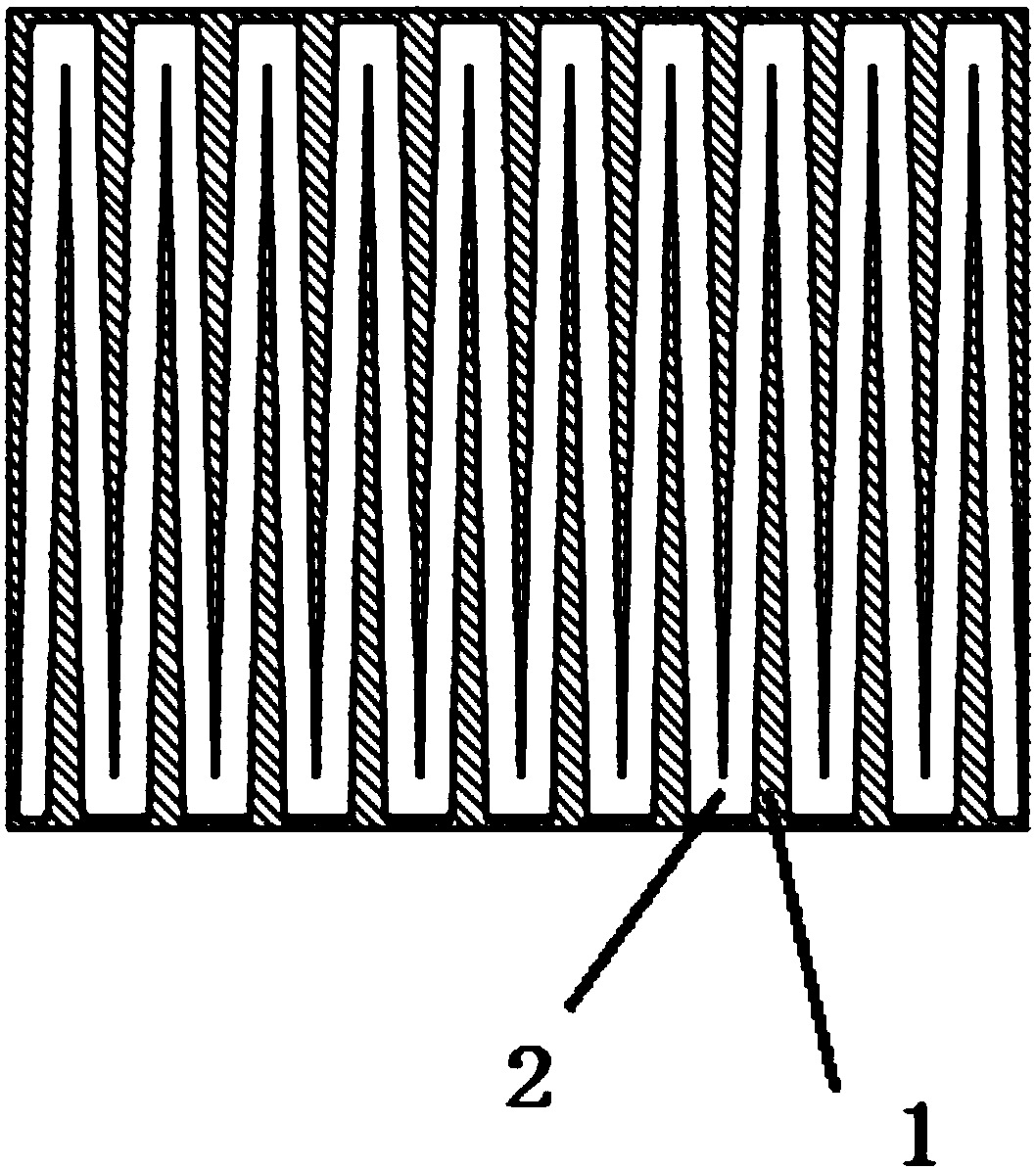

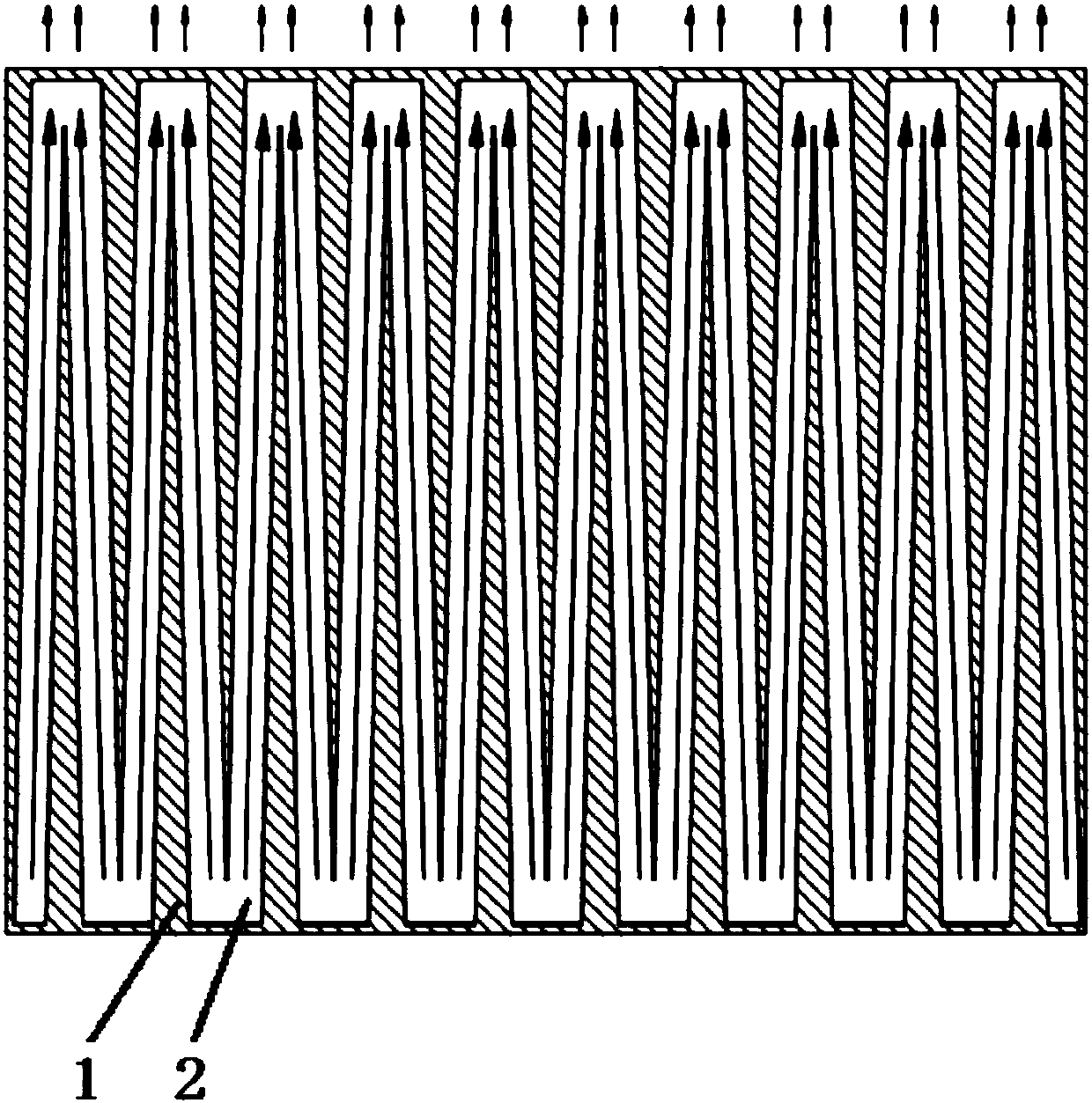

[0031] Step 2, folding the synthetic graphite sheet;

[0032] Step 3, placing the folded graphite sheet into a forming mold for shaping, with a filling volume of 18%;

[0033] Step 4: Bake the mixture in an oven at 100°C for 30 minutes and take it out after it is completely solidified. After the material is completely cooled, die-cut according to actual needs to obtain materials of corresponding specifications.

[0034] The present invention changes the horizontal direction of the graphite sheet into the vertical direction of the material by folding the graphite sheet, so that the vertical thermal conductivity of the material is close to the horizontal thermal conductivity of the graphite sheet; the polymer flexible body is used as the outer layer of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com