Transmission mechanism for large circular knitting machine and assembling method thereof

A transmission mechanism and assembly method technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of large intermediate shaft torque, unstable rotation of the intermediate shaft, and influence on the accuracy of woven fabrics, so as to reduce friction, The effect of improving the quality of finished products and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

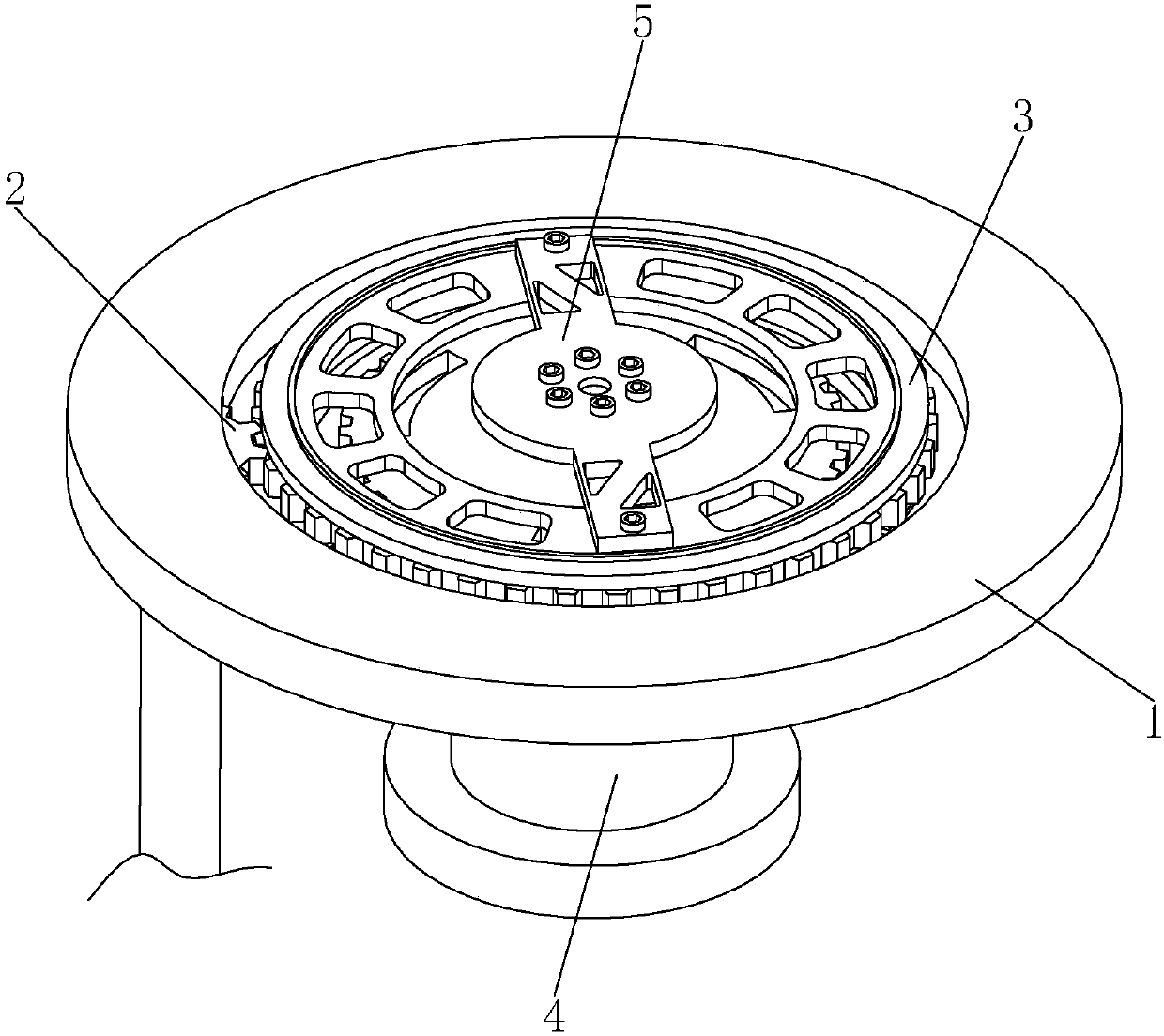

[0042] Embodiment 1: A transmission mechanism of a large circular knitting machine, as shown in Figure 1, includes a large tripod 1, a large tripod gear 3, a main drive pinion 2, a connecting seat 5, and a barrel 4.

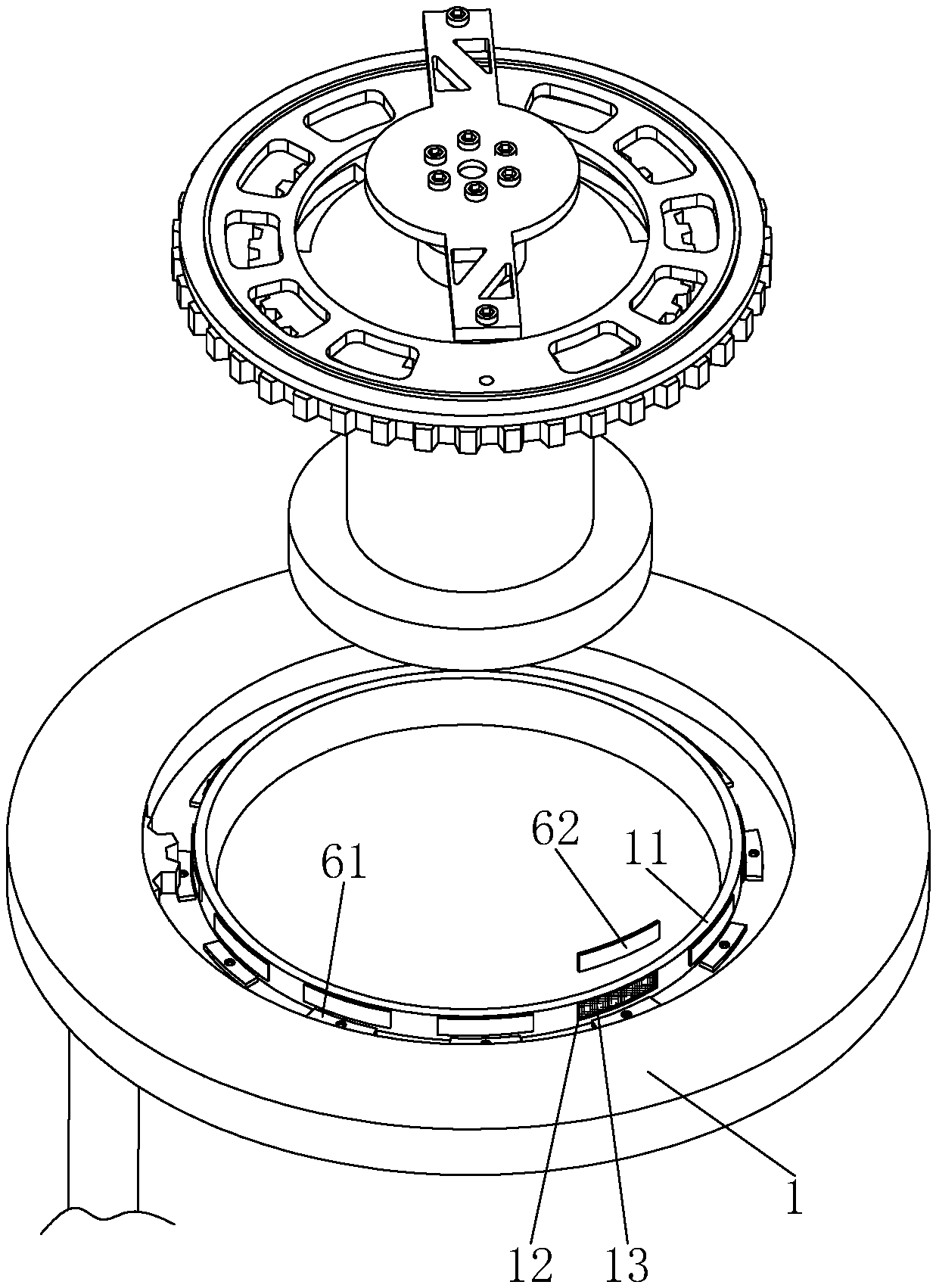

[0043] like figure 2 As shown, an arc-shaped mounting seat 11 with an "L"-shaped cross-section is formed near the edge of the large tripod 1. The right-angled jaw formed on the mounting seat 11 faces away from the middle of the large tripod 1. When the mounting seat 11 is away from On the outer wall of the middle part of the big tripod 1, there are 12 grooves 12 distributed in a circular array on the center line of the big tripod 1. A rough anti-skid layer 13 is formed at the bottom of the grooves 12. In the grooves 12, there are glued Wear-resistant skin 62, and the end faces of multiple wear-resistant sheets 61 away from the middle of the tripod 1 are all on the same circumferential surface. There are 12 wear-resistant sheets 61 fixedly connected by bolts on t...

Embodiment 2

[0046] Embodiment 2: A kind of assembly method of the transmission mechanism of large circular knitting machine, coordinate figure 1 and figure 2 , including the following steps S1 to S4.

[0047] Step S1: Grinding on the large tripod 1 with a centerless grinder to form a smooth mounting base 11 .

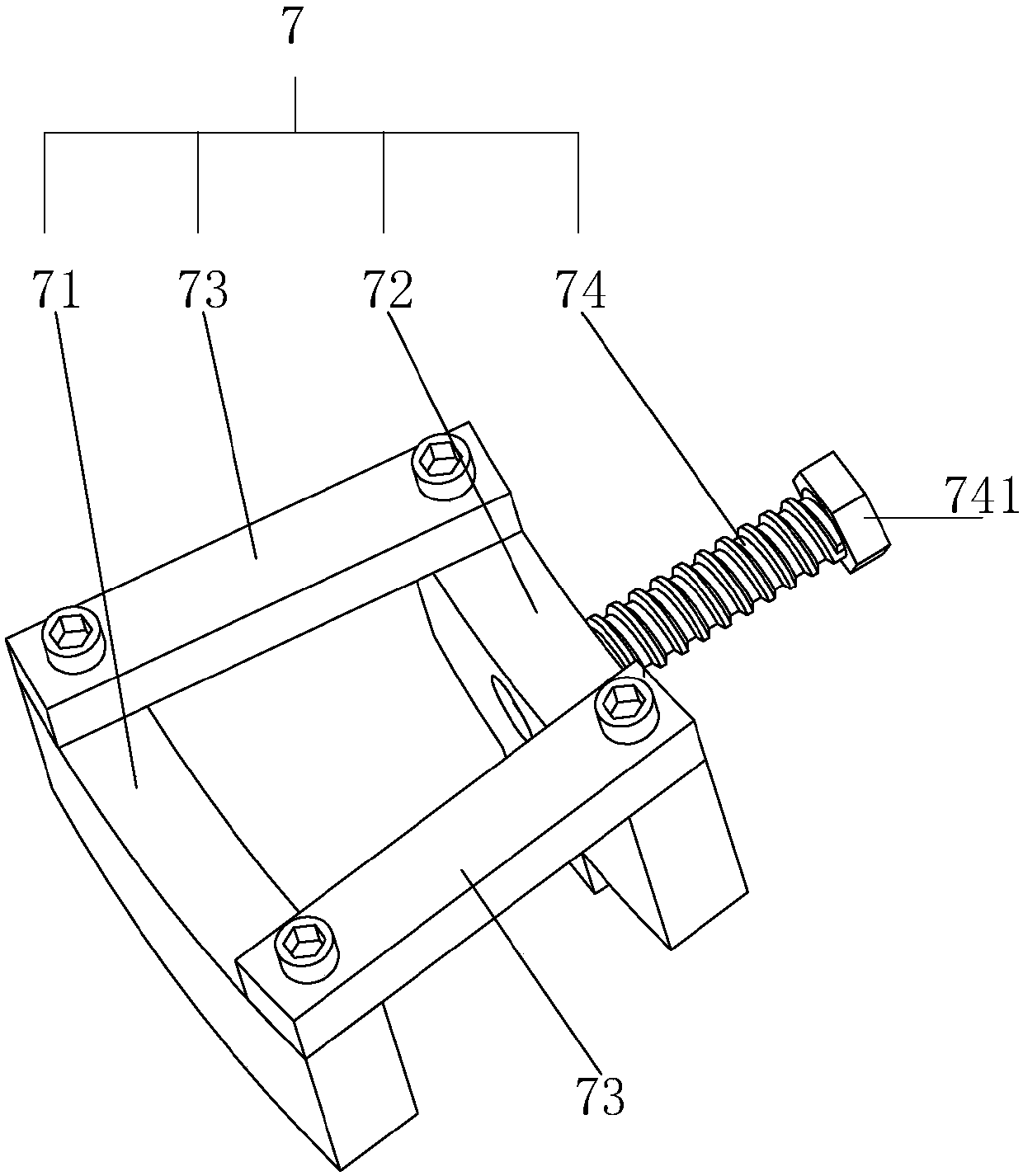

[0048] Step S2: (1) Create 12 grooves 12 on the side wall of the mounting seat 11 through the CNC machining center, and use a chisel to grind the bottom of the grooves 12 to form a rough anti-skid layer 13; (2) through the oil stain The cleaning agent cleans the surface of the tripod 1, focusing on removing the oil and impurities at the groove 12; (3) Bond the wear-resistant skin 62 in the groove 12 with glue, stick it on the mounting seat 11 with waterproof paper and completely cover the groove Groove 12; (4) make 12 clamps 7 through the limit device 8 (see image 3 ) At the same time, the 12 wear-resistant skins 62 are clamped on the mounting seat 11, so that the wear-resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com