Construction process of filling type epoxy coating steel strand inhaul cables

A technology of epoxy coating and construction technology, which is applied in the direction of bridge parts, erection/assembly bridges, bridges, etc., can solve the problems of imperfect protective measures, achieve great economic value and social benefits, and achieve scientific and reasonable construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

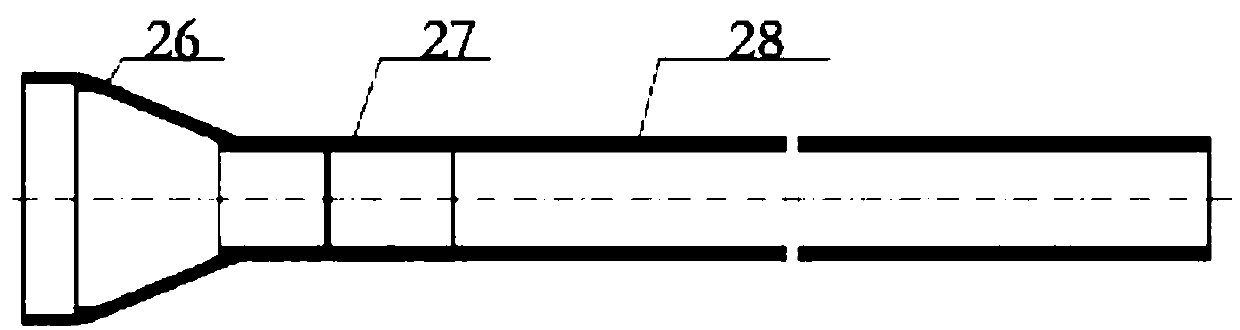

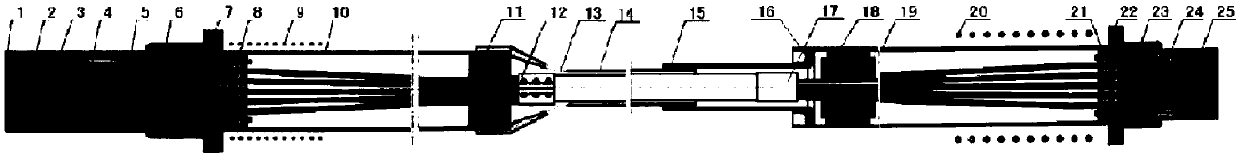

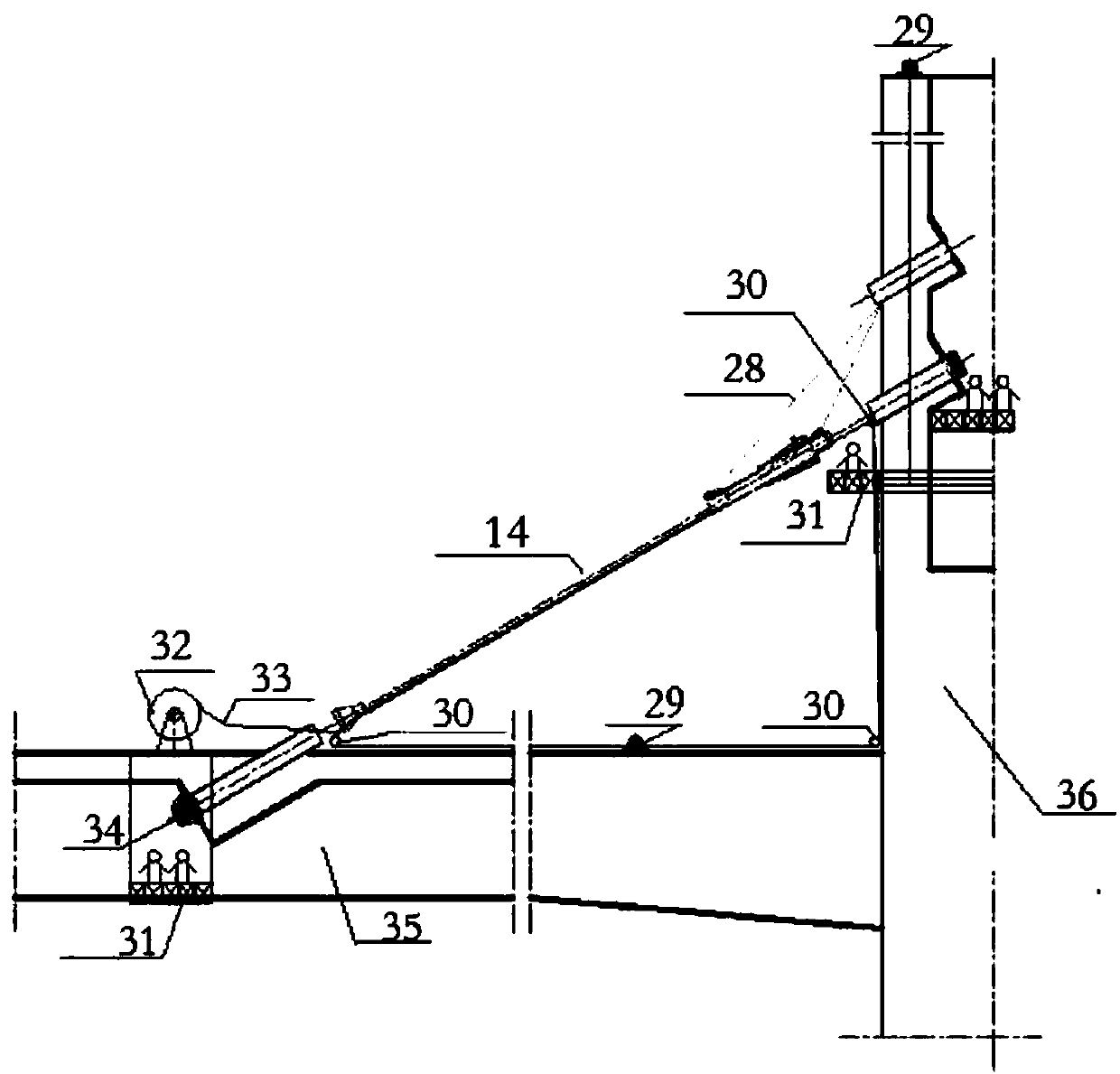

[0054] Attached below figure 1 -8 and embodiment further illustrate the present invention:

[0055] A construction process of a filled epoxy-coated steel strand cable is carried out according to the following construction contents:

[0056] 1. Preparations before hanging the rope

[0057] 1.1, HDPE casing welding

[0058] 1.1.1. Prefabrication area preparation

[0059] The welding work requires a rectangular work area of 2m×120m. The main girder of the bridge in this embodiment is constructed by cantilever cast-in-place construction. For the short-cable HDPE pipe welding, it can be welded on the casted box girder near the root of the tower No. 1-6 and according to the cable number of the welded HDPE pipe, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com