Airtight coring tool and airtight coring drilling process

A technology of airtight coring and coring bits, which is applied in the direction of extracting undisturbed core devices, earthwork drilling, etc., can solve problems such as core pollution and impact on core quality, increase credibility, improve exploration efficiency and accuracy, shorten The effect of exploration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

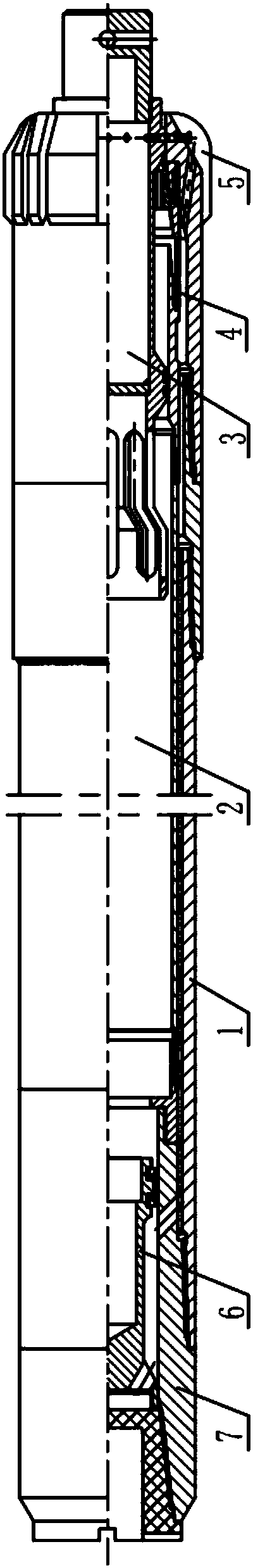

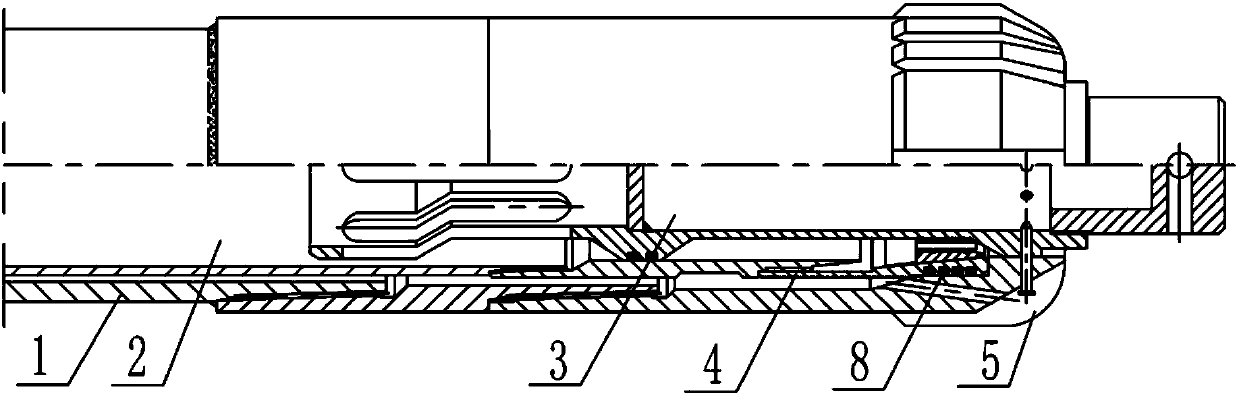

[0022] Embodiment 1: A closed coring tool, including an outer cylinder 1, an inner cylinder 2, a sealing device 3, a core claw assembly 4 and a core bit 5, and the inner cylinder 2 is set in the outer cylinder 1 , the bottom end of the inner cylinder 2 is threaded with the core jaw assembly 4, the bottom end of the outer cylinder 1 is threaded with the core bit 5, and the sealing device 3 is connected with the core The inner wall of the claw assembly 4 is sealed and connected, and the sealing device 3 includes a body 31 and a first sealing ring 32. The top end of the body 31 is located in the inner cylinder 2, and the bottom end is located in the extraction. Outside the core bit 5 , the first seal ring 32 is arranged on the body 31 , and the body 31 is sealingly connected with the inner wall of the core jaw assembly 4 through the first seal ring 32 . At the beginning of coring, the bottom of the sealing device 3 first contacts the bottom of the well, and the rock at the bottom...

Embodiment 2

[0023] Embodiment 2: Preferably, on the basis of Embodiment 1, a notch 33 is provided on the top of the body 31, and a positioning pin 34 is also provided on the body 31, and the body 31 is positioned by The pin 34 is fixedly connected with the core bit 5 . By setting the gap 33, the core sealing fluid can overflow from the gap 33, and when the first sealing ring 32 fails, the sealing fluid can pass through the gap 33, quickly flow out from the inner cylinder 2 and wrap the core. By arranging the positioning pin 34, the first sealing device is fixed on the core bit 5, which enhances the stability of the sealing device 3, and avoids the first sealing device from being unstable from the coring tool when the coring tool is lowered. The middle slides out, causing the first sealing ring 32 to fail early, affecting the coring process. The positioning pin 34 can not only fix the sealing device 3, but also not affect the failure of the first sealing ring 32, because in the coring pro...

Embodiment 3

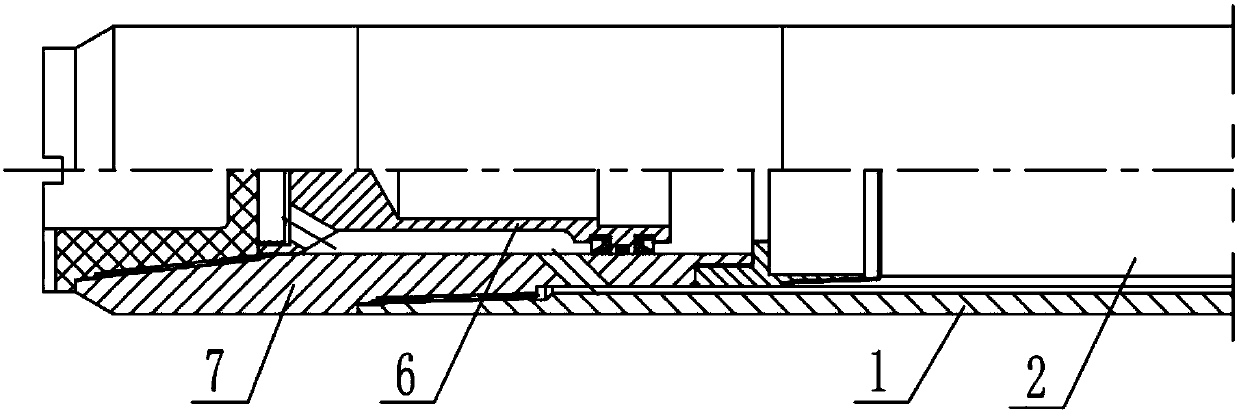

[0024] Embodiment 3: Preferably, on the basis of Embodiment 1 or 2, a balance piston 6 is arranged on the top of the inner cylinder 2 , and the balance piston 6 is used to seal the inner cylinder 2 . By setting the balance piston 6 on the top of the inner cylinder 2, the top of the inner cylinder 2 is sealed to prevent the core sealing fluid from overflowing from the top of the inner cylinder 2 during the coring process, damaging the coring tool and affecting the coring effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com