Device and method capable of simulating underground true environment to test gas-liquid separation efficiency of centrifugal pump

A real environment and testing device technology, applied in pump control, non-variable pumps, machines/engines, etc., can solve the problems of inaccurate simulation results, inability to simulate centrifugal pumps and gas-liquid separators, etc., to achieve convenient measurement and realization The effect of online real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

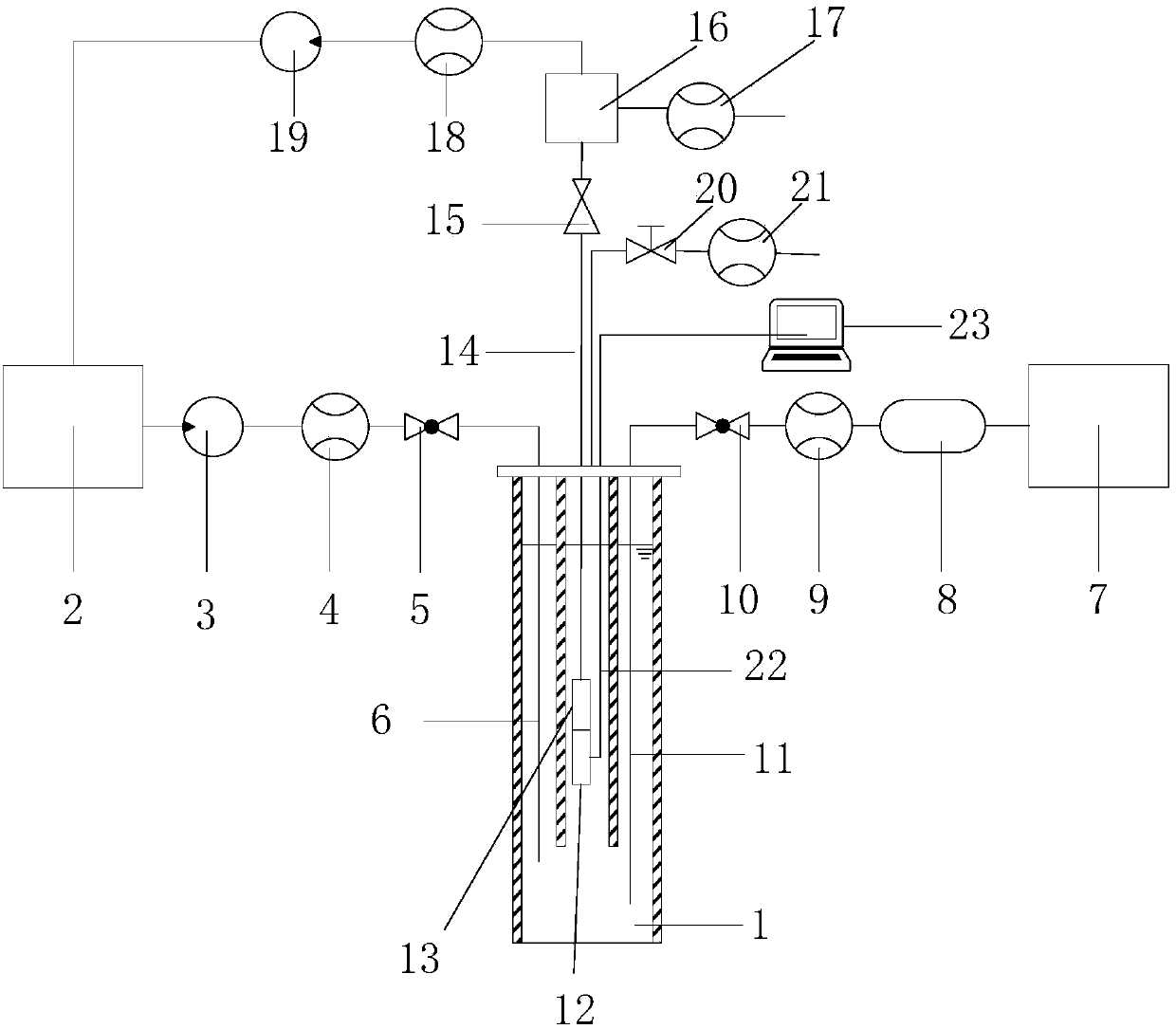

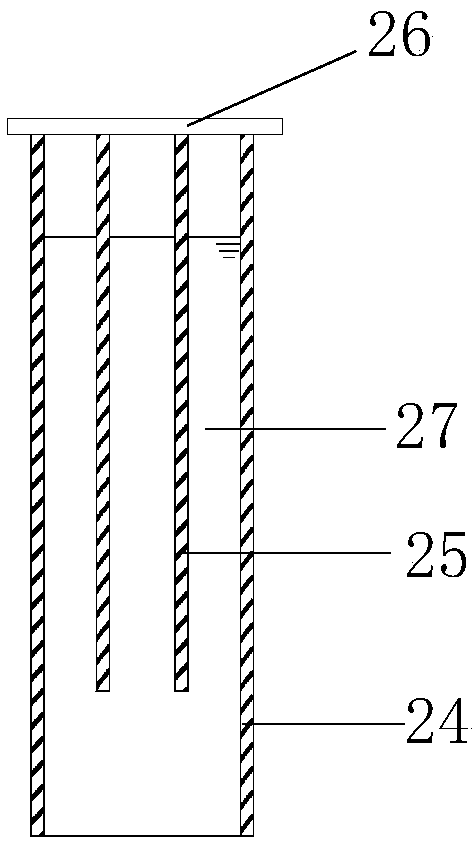

[0028] Embodiment 1 provides a device for testing the gas-liquid separation efficiency of centrifugal pumps by simulating the real downhole environment, such as figure 1 with 2 As shown, it includes an underground simulated well 1, a water tank 2, an air compressor 7, a vacuum deaerator 16, and a centrifugal pump control and data collector 23.

[0029] The wellhead of the underground simulated wellbore 1 is sealed by a wellhead ring plate 26, and a second casing 25 and a first casing 24 are sequentially arranged in the underground simulated wellbore 1 from inside to outside, and the first casing 24 is close to the underground simulation The inner wall of the wellbore 1 is arranged, an annulus 27 is formed between the first casing 24 and the second casing 25, and the tops of the first casing 24 and the second casing 25 are respectively sealed with the wellhead ring plate 26. Wherein, the first sleeve 24 uses a 16" sleeve, and the second sleeve 25 uses a 9-5 / 8" sleeve.

[0030] A wat...

Embodiment 2

[0040] Corresponding to the device of Embodiment 1, Embodiment 2 provides a method for testing the gas-liquid separation efficiency of a centrifugal pump by simulating a real downhole environment, including the following steps:

[0041] S1. Check and calibrate each instrument and equipment to make it in normal working condition;

[0042] S2. Fill the water tank with water, turn on the pipeline pump, and fill the underground simulated wellbore with water;

[0043] S3. Turn on the air compressor to inject gas into the underground simulated wellbore at a fixed flow rate;

[0044] S4. Turn on the centrifugal pump. After the gas-liquid mixture in the underground simulated wellbore passes through the gas-liquid separator, it is lifted to the ground by the centrifugal pump. After passing through the vacuum deaerator, the water returns to the water tank and the gas is discharged to the outside;

[0045] S5. Measure the amount of gas separated by the gas-liquid separator and the amount of gas se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com