Burr detector for valve body

A burr detection machine and valve body technology, applied in the direction of conveyor objects, optical testing flaws/defects, sorting, etc., can solve problems that affect product performance, dead ends, and cannot be removed, so as to improve production quality and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

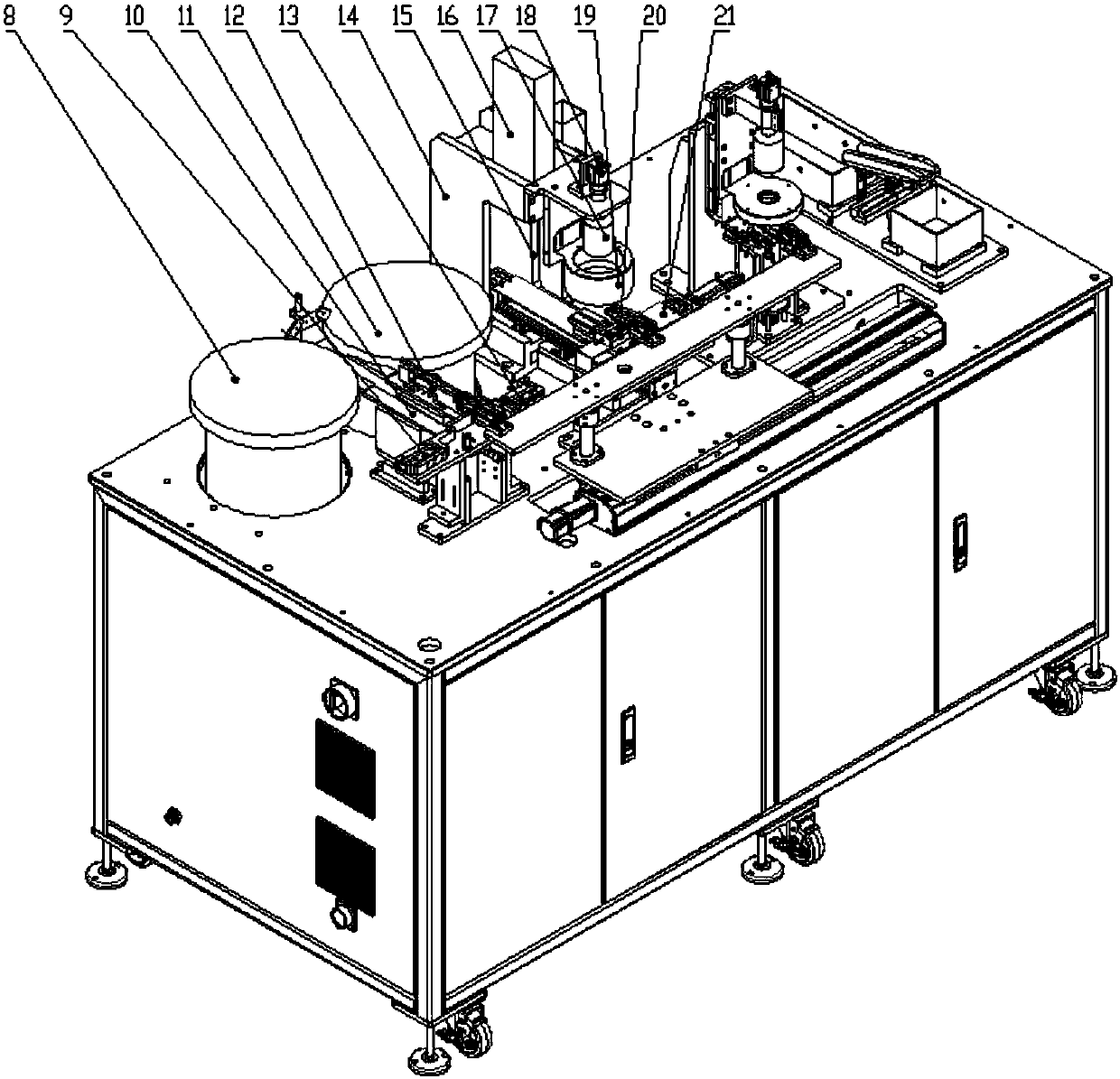

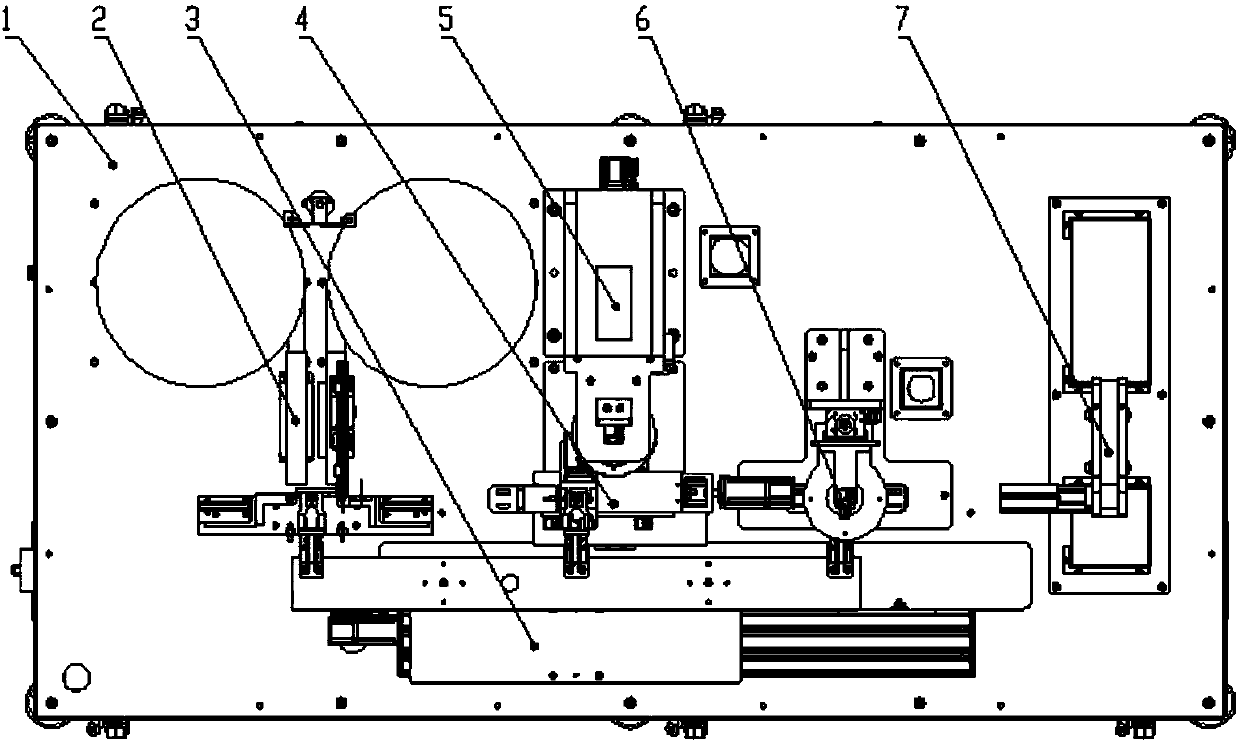

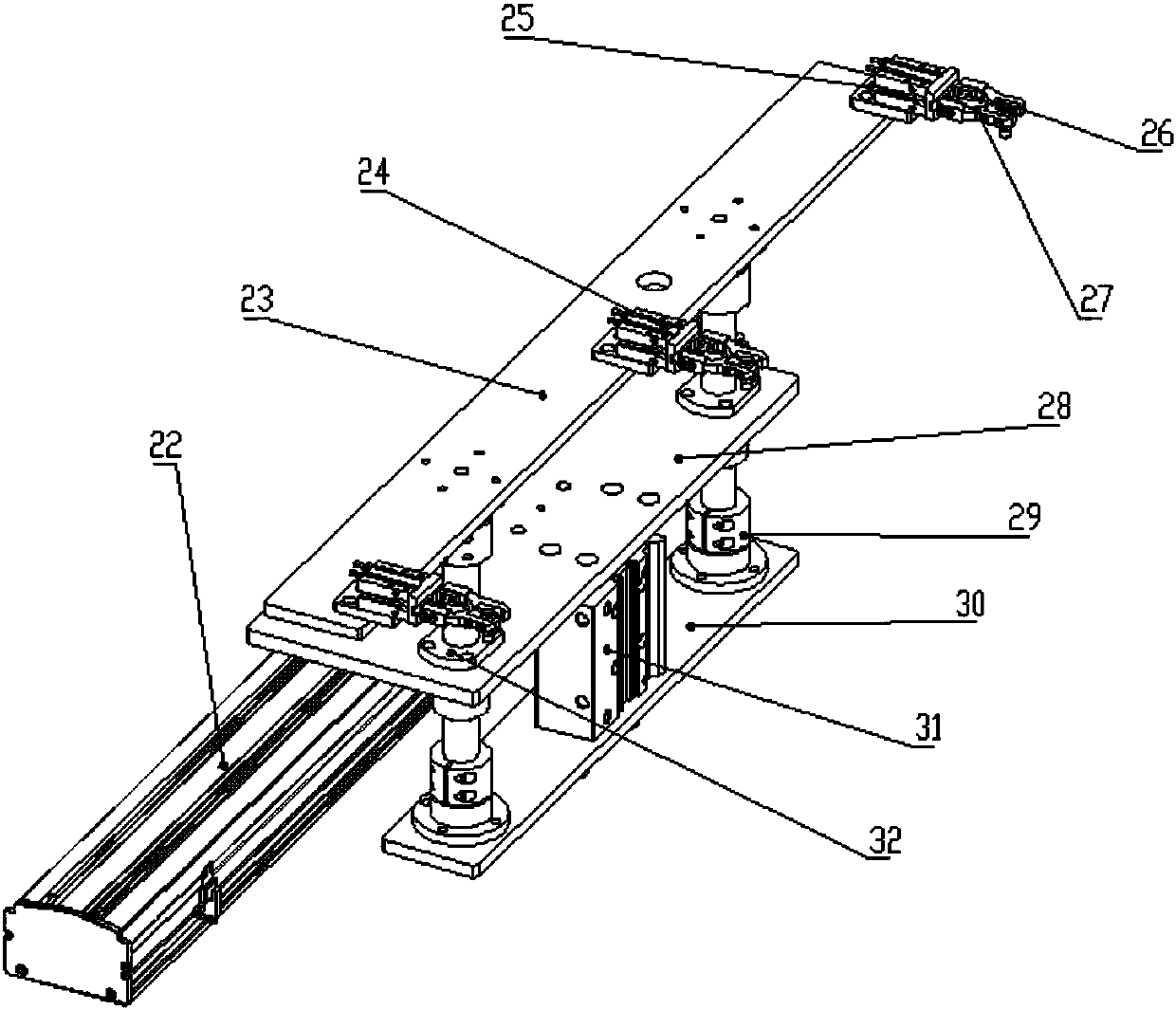

[0025] Such as figure 1 , 2 As shown, the specific embodiment of the present invention: a valve body burr detection machine, comprising: a frame 1, a feeding device 2, a material transfer device 3, a positioning device 4, a blank holder 5, a detection device 6, and a feeding device 7. A feeding device 2, a material transfer device 3, a positioning device 4, a blanking device 5, a detection device 6, and a feeding device 7 are evenly distributed on the table of the frame 1, and the feeding device 2 includes a valve body I vibrating plate 8, valve body I distributing mechanism 9, valve body I feeding track 10, valve body II vibrating plate 11, valve body II feeding track 12, valve body II distributing mechanism 13, the valve body I vibrates Disc 8 and valve body II vibrating disc 11 are provided with valve body I feeding track 10 and valve body II feeding track 12 respectively at the edge of the side disc, the valve body I feeding track 10 and valve body II feeding track 12 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com