Method for dehydrating and pickling mustard tuber

A technology of mustard and water, which is applied in the field of mustard processing, can solve environmental problems such as pollution and sewage discharge, and achieve the effects of reducing environmental pollution, reducing sewage discharge, and increasing shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

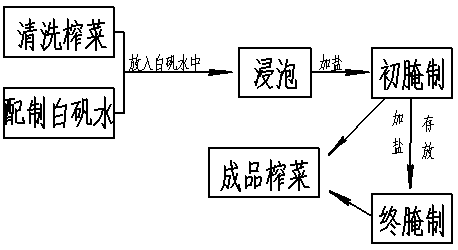

Image

Examples

Embodiment approach

[0045] Preferred embodiment of the present invention: the alum water is made into a 1:10 alum aqueous solution, the pickled mustard after cleaning is put into the alum water and soaked for 4 hours, picks up, puts into the mustard pickling pool that can shelter from the rain, weighs 100 jin The ratio of mustard mustard 4 jins of salt is mixed with salt and pressed tightly to seal the pickling pool. After the mustard is pickled in the pickling pond for 8 days, the pickling pond is opened, the pickled mustard in the pickling pond is picked up for further processing, and the remaining mustard water in the pickling pond is collected for boiling mustard soy sauce. Since the pre-pickled mustard can not be stored for a long time, in order to maintain the quality characteristics of the finished mustard in green color, softness, tenderness, and fragrance, the mustard after the initial pickling is put into the mustard pickling pool that can avoid rain and press 100 The ratio of 5 jin of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com