Filth collection and deodorization equipment for gastroenterology department

A gastroenterology, filth technology, applied in the direction of saliva-receiving appliances, etc., can solve the problems of difficult patients to spit accurate collection basin, unable to isolate filth and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

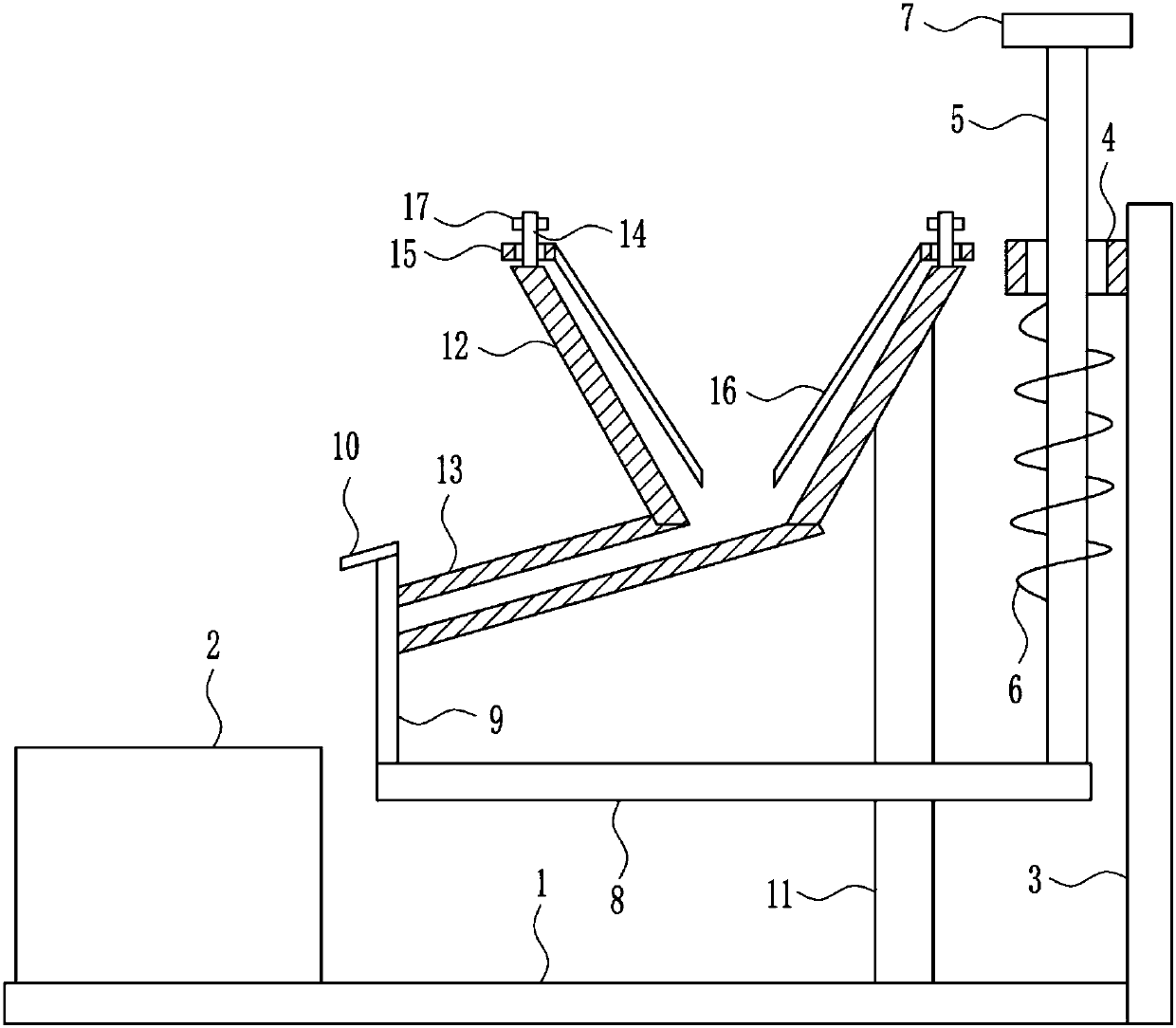

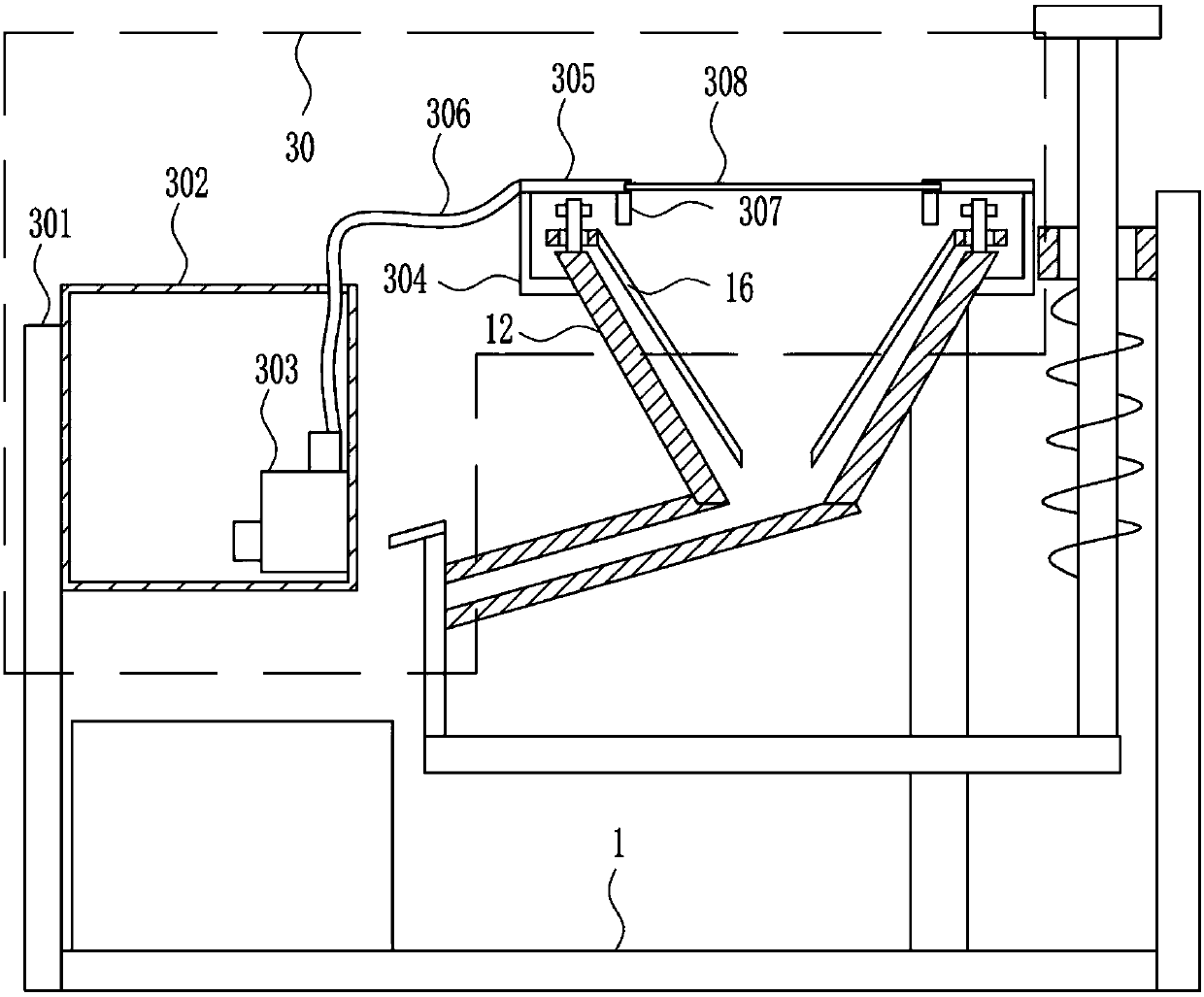

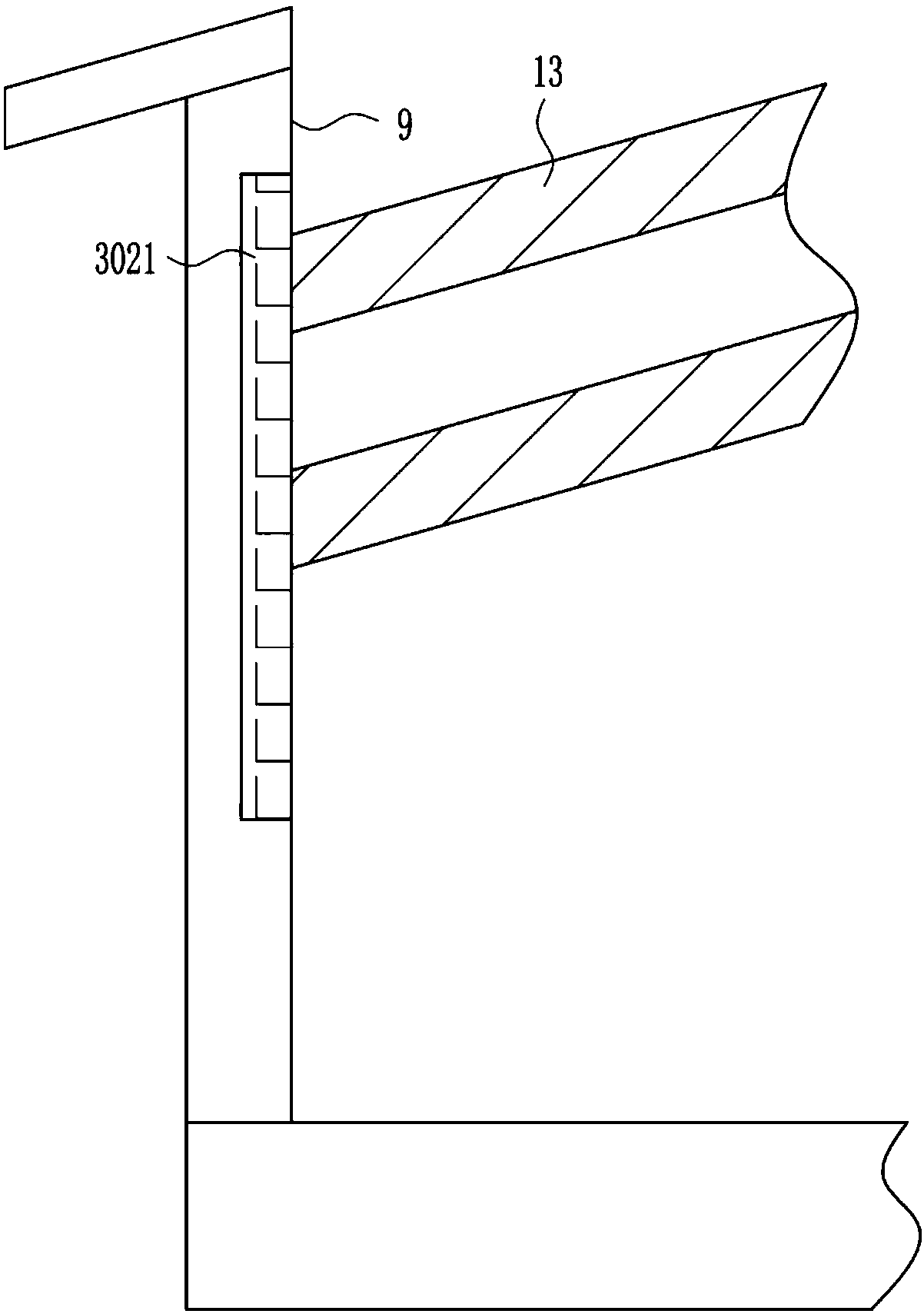

[0028] A gastroenterology waste collection deodorization equipment, such as Figure 1-5As shown, it includes a bottom plate 1, a collection box 2, a first support plate 3, a guide sleeve 4, a guide rail 5, a spring 6, a push block 7, a connecting rod 8, a baffle plate 9, a first guide block 10, and a second support Plate 11, collecting bucket 12, diversion pipe 13, screw rod 14, fixed block 15, deflector plate 16 and nut 17, collecting box 2 is placed on the left side of the base plate 1, and the right end of the base plate 1 is installed with the first support by welding Plate 3, a guide sleeve 4 is installed by welding on the upper left side of the first support plate 3, a guide rail 5 is slidably connected to the inside of the guide sleeve 4, a spring 6 is installed on the lower side of the guide sleeve 4 by welding, and the lower end of the spring 6 passes through It is connected to the lower side of the guide rail 5 by welding, the upper end of the guide rail 5 is install...

Embodiment 2

[0030] A gastroenterology waste collection deodorization equipment, such as Figure 1-5 As shown, it includes a bottom plate 1, a collection box 2, a first support plate 3, a guide sleeve 4, a guide rail 5, a spring 6, a push block 7, a connecting rod 8, a baffle plate 9, a first guide block 10, and a second support Plate 11, collecting bucket 12, diversion pipe 13, screw rod 14, fixed block 15, deflector plate 16 and nut 17, collecting box 2 is placed on the left side of the base plate 1, and the right end of the base plate 1 is installed with the first support by welding Plate 3, a guide sleeve 4 is installed by welding on the upper left side of the first support plate 3, a guide rail 5 is slidably connected to the inside of the guide sleeve 4, a spring 6 is installed on the lower side of the guide sleeve 4 by welding, and the lower end of the spring 6 passes through It is connected to the lower side of the guide rail 5 by welding, the upper end of the guide rail 5 is instal...

Embodiment 3

[0033] A gastroenterology waste collection deodorization equipment, such as Figure 1-5 As shown, it includes a bottom plate 1, a collection box 2, a first support plate 3, a guide sleeve 4, a guide rail 5, a spring 6, a push block 7, a connecting rod 8, a baffle plate 9, a first guide block 10, and a second support Plate 11, collecting bucket 12, diversion pipe 13, screw rod 14, fixed block 15, deflector plate 16 and nut 17, collecting box 2 is placed on the left side of the base plate 1, and the right end of the base plate 1 is installed with the first support by welding Plate 3, a guide sleeve 4 is installed by welding on the upper left side of the first support plate 3, a guide rail 5 is slidably connected to the inside of the guide sleeve 4, a spring 6 is installed on the lower side of the guide sleeve 4 by welding, and the lower end of the spring 6 passes through It is connected to the lower side of the guide rail 5 by welding, the upper end of the guide rail 5 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com