Automatic stalk picking machine for oolong tea

A technology of oolong tea and stem inspection machine, which is applied in tea treatment before extraction, solid separation, filtration and sieving, etc. It can solve the problems of low efficiency and high cost, achieve better color and fragrance, reduce selection cost, and improve selection work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

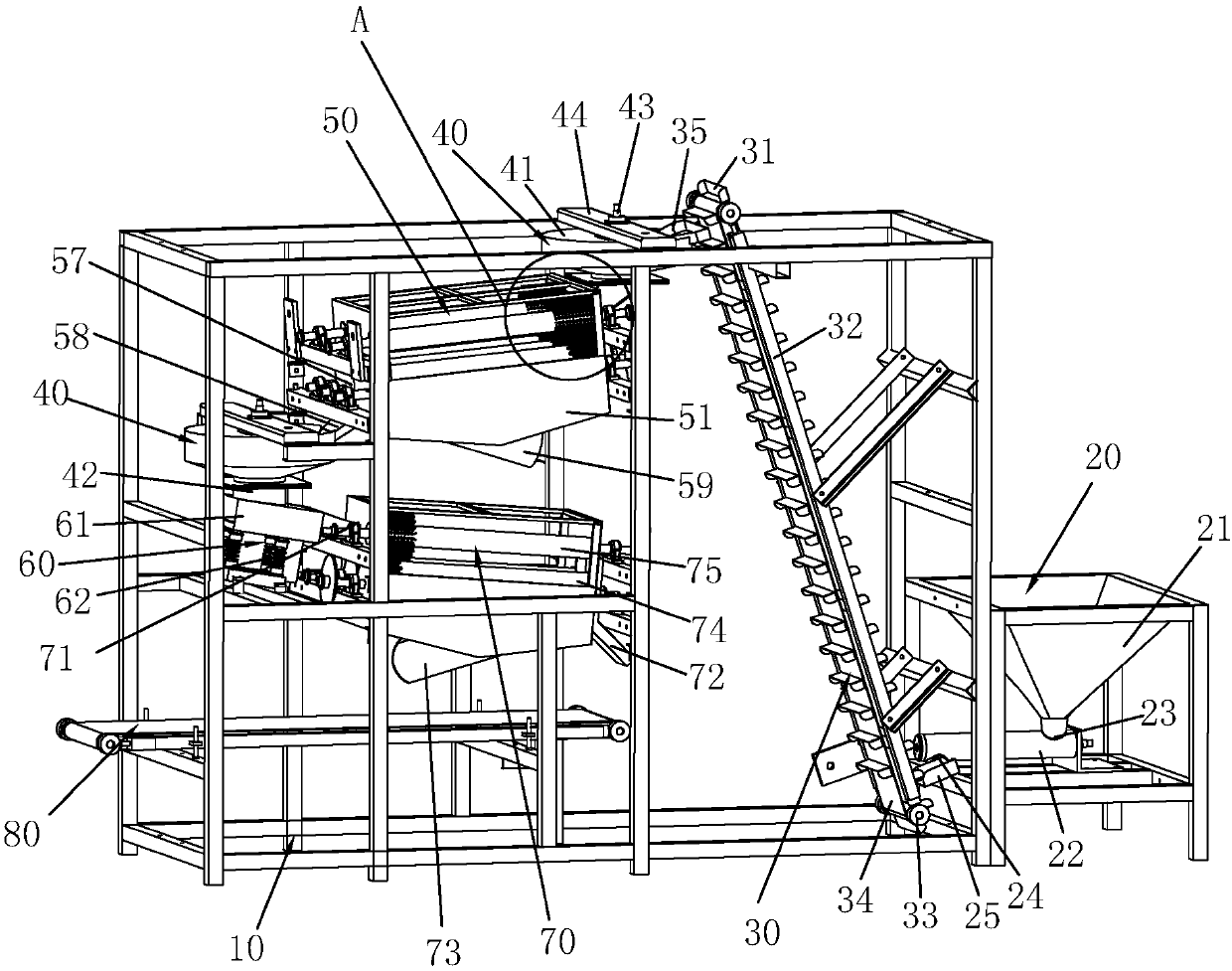

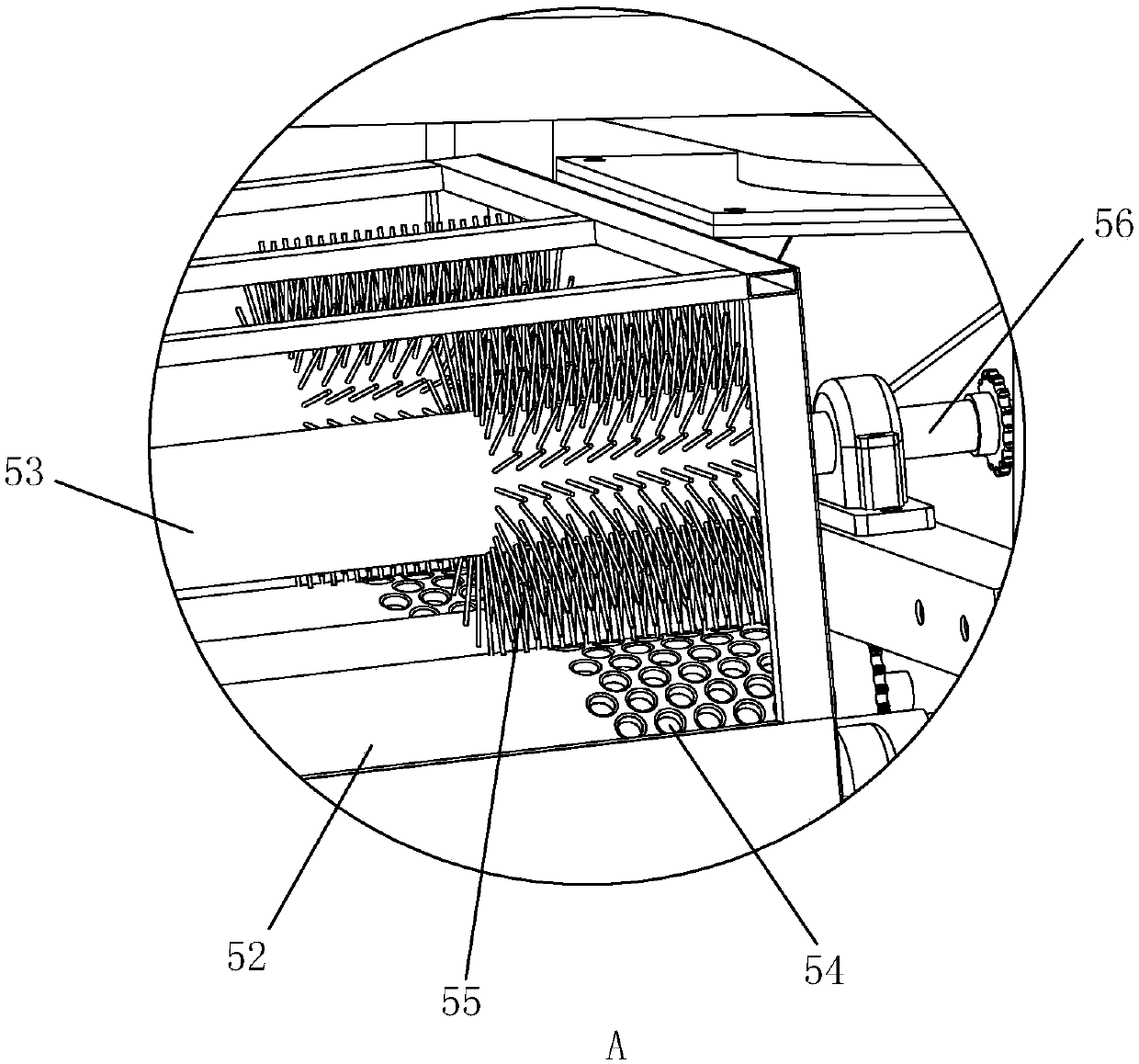

[0013] Such as figure 1 As shown, the oolong tea automatic stem detection machine of the present invention includes a support 10, a feeding mechanism 20, an automatic feeding ladder 30, a screw transfer cylinder 40, a first leaf stem separation device 50, a discharge vibration device 60, and a second leaf stem separation device. The device 70, the feeding belt 80, and the bracket 10 play a role of supporting and fixing the entire oolong tea automatic stem detection machine.

[0014] Such as figure 1 As shown, the unloading mechanism 20 is arranged on the side of the support 10 . The feeding mechanism 20 includes a feeding funnel 21, the feeding funnel 21 is used for feeding raw tea, the lower end of the feeding funnel 21 is matched with a feeding pipe 22, the upper side opening 23 at one end of the feeding pipe 22, the upper opening 23 is connected with the feeding funnel 21, that is, raw tea enters from the feeding funnel 21 and then enters the feeding pipe 22 from the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com