Automobile part fixture device

A technology of auto parts and tooling fixtures, which is applied in the direction of workpiece clamping devices and manufacturing tools, and can solve the problems of workpiece scrap rate and high processing cost, workpiece drift, and poor fixing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

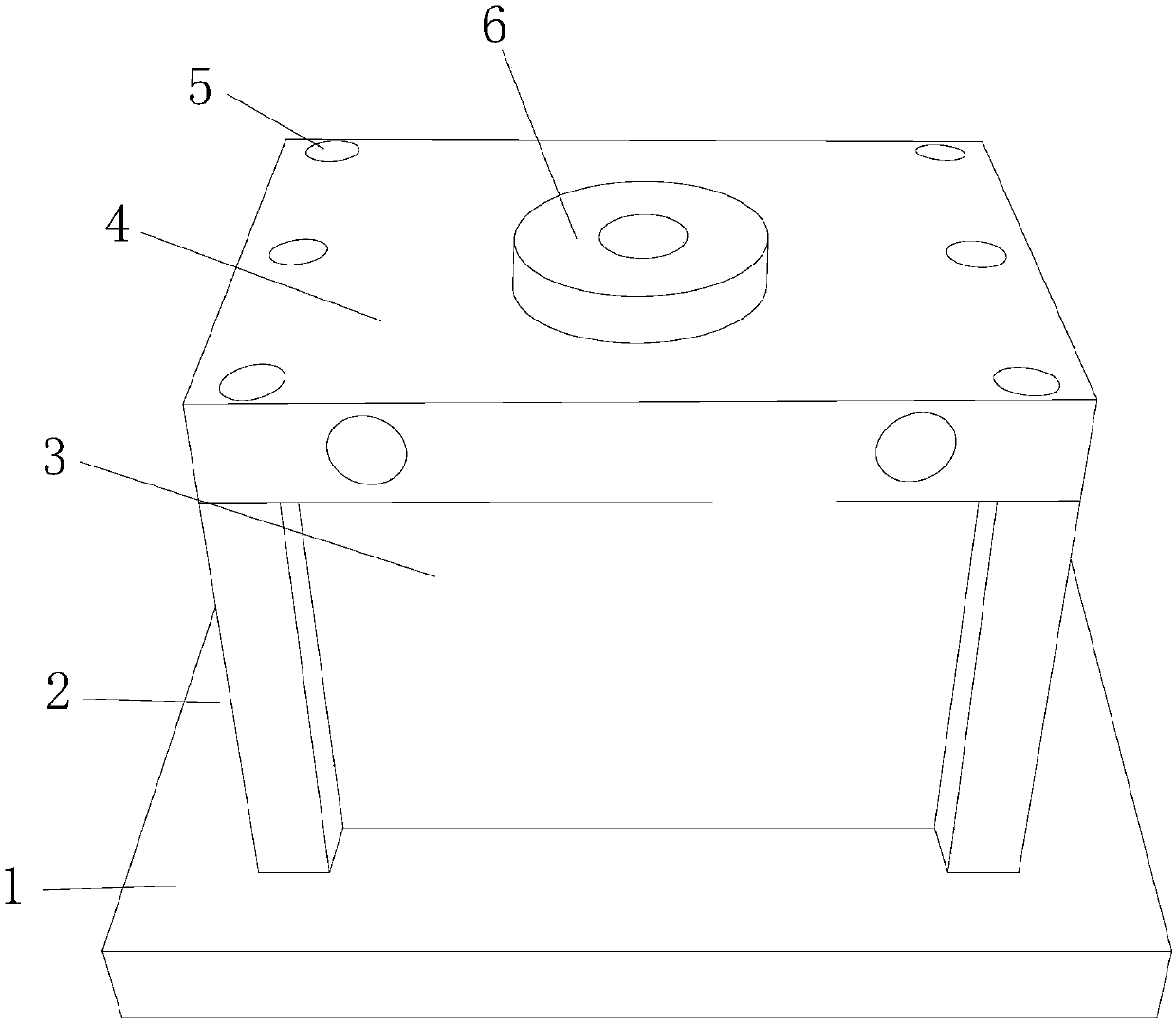

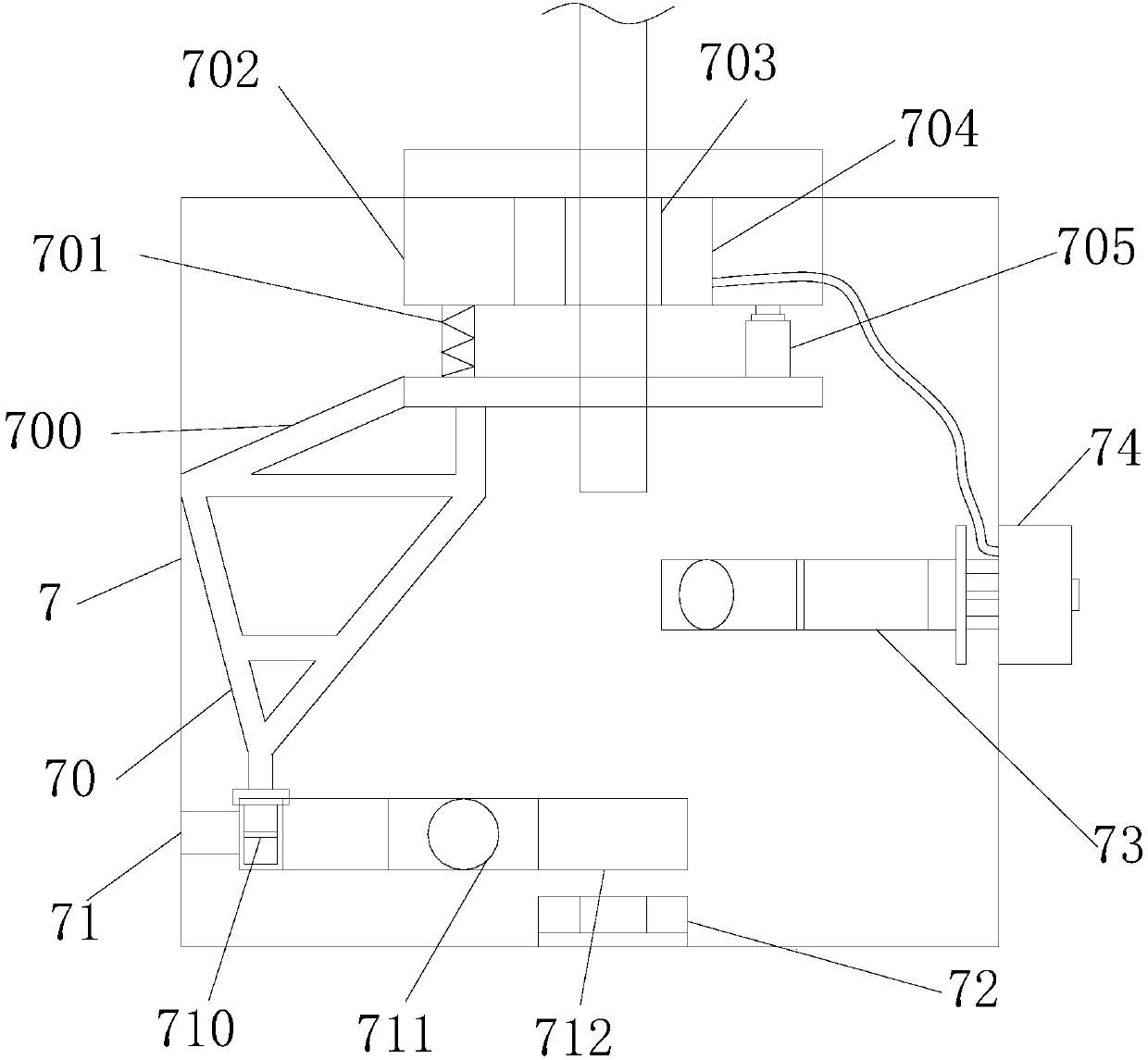

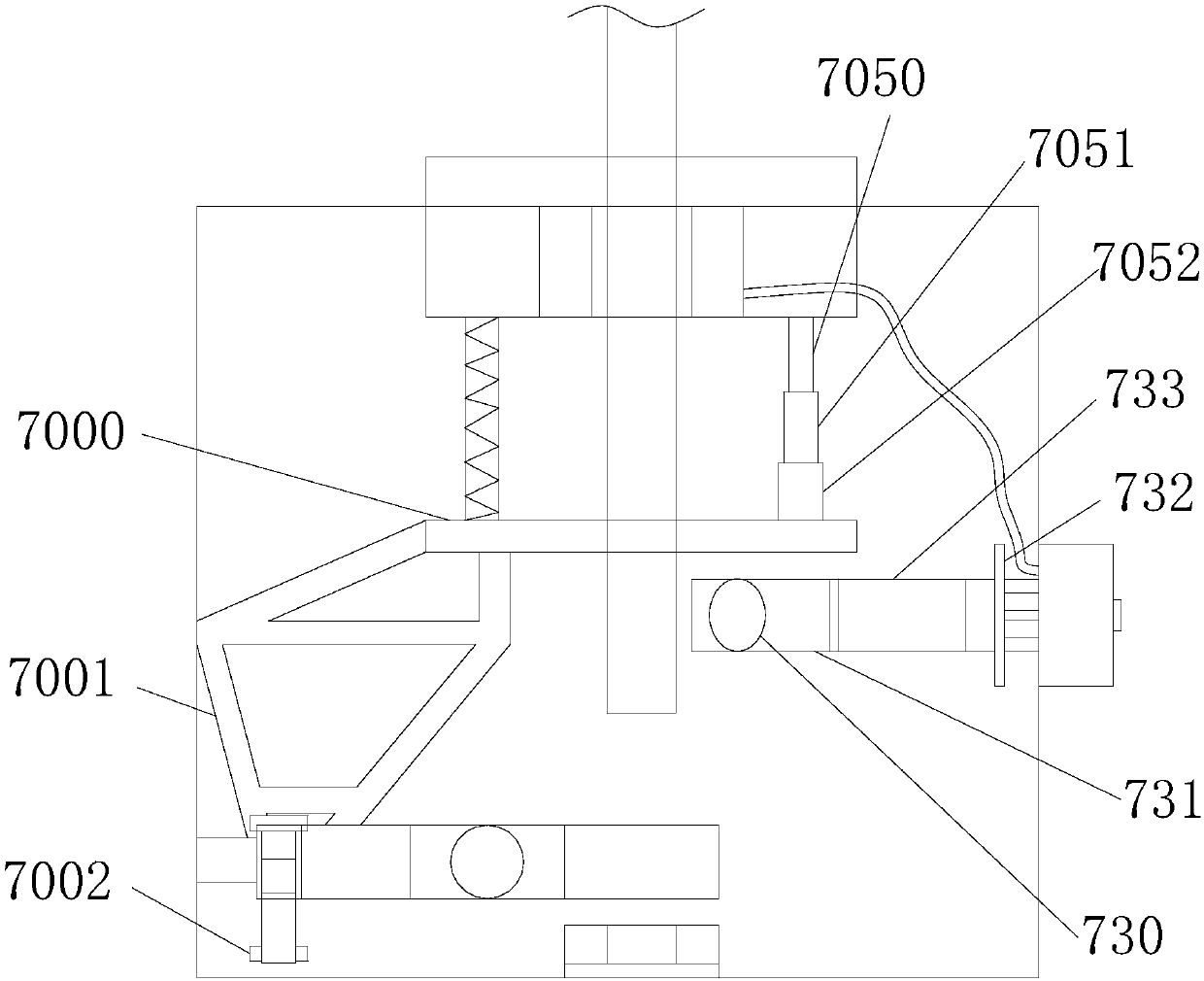

[0020] see Figure 1-Figure 4, the present invention provides a tooling fixture device for auto parts: its structure includes a mounting base 1, a fixed pole 2, a fixed frame 3, an upper cover plate 4, a bolt lock 5, an entry rod ring 6, and a fixing device 7. The installation base 1, the fixed pole 2, the fixed frame 3, and the upper cover plate 4 are respectively in a rectangular structure, and the fixed poles 2 are provided with four, arranged on the upper surface of the base 1 in a rectangular structure, and the fixed poles 2 The bottom is welded to the upper surface of the mounting base 1, the upper end surface of the fixed pole 2 is mechanically connected to the four corners of the bottom of the upper cover plate 4, and the fixed square frame 3 and the upper cover plate 4 form an inverted U-shaped structure. There are more than 3 latches 5, the fixed frame 3 and the upper cover 4 are locked by the latch 5, and the fixed frame 3 is set in the inner frame composed of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com