Sickle numerical control punching cutting-off device

A technology of cutting device and sickle, which is applied in the direction of wood stamping, etc., can solve the problems of intelligence, low degree of automation, cumbersome operation, etc., and achieve the effect of reducing labor intensity, simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

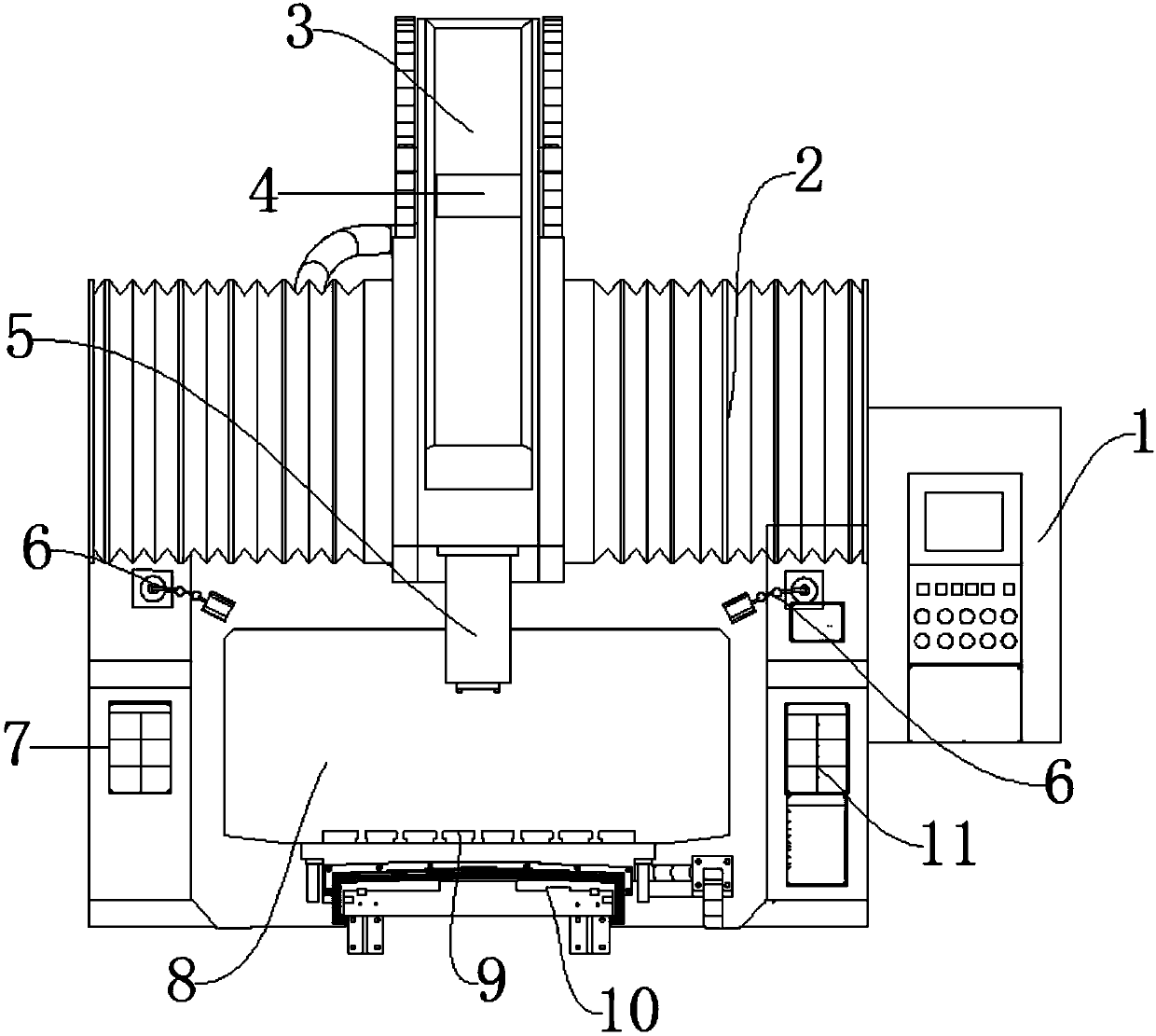

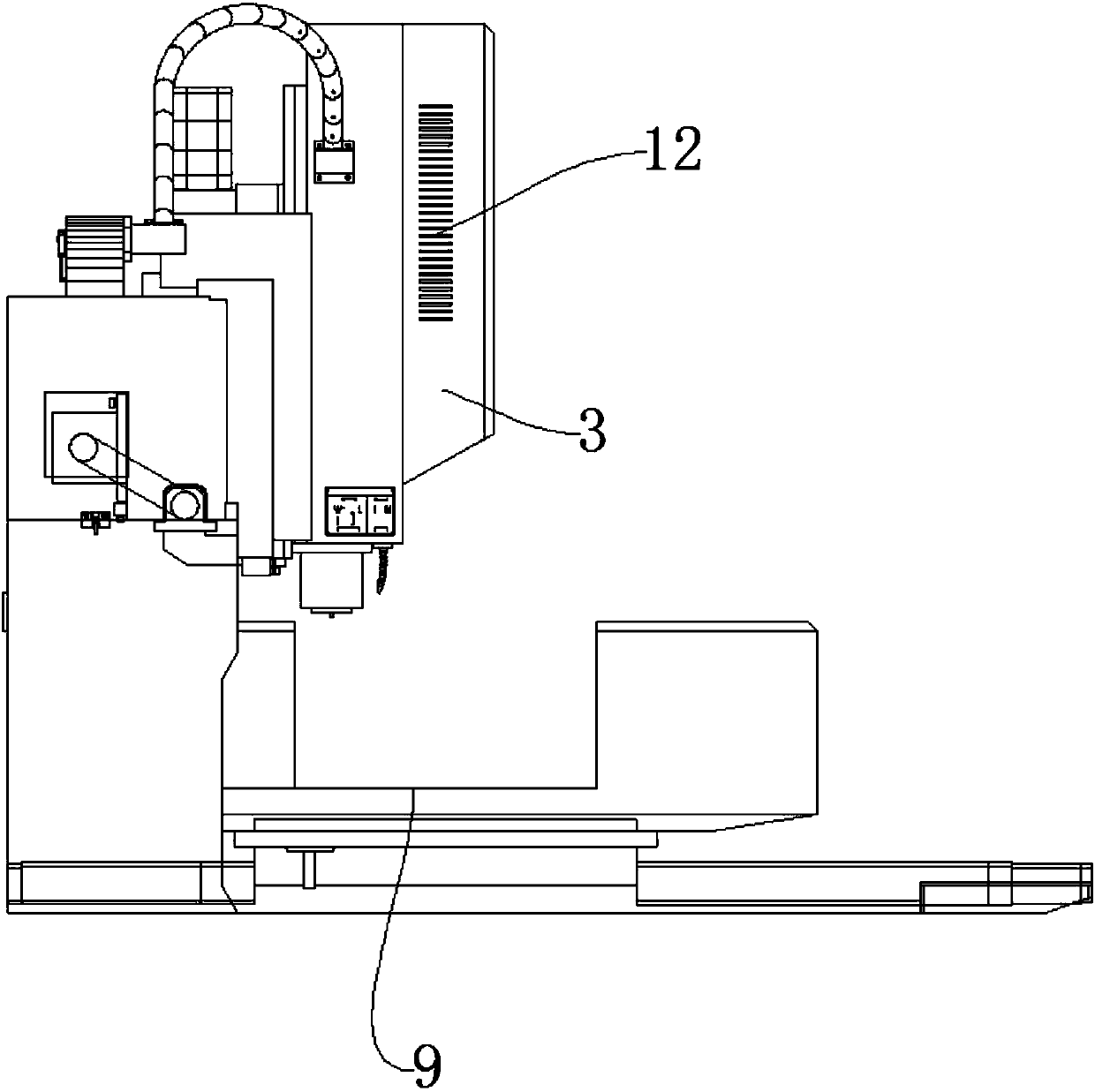

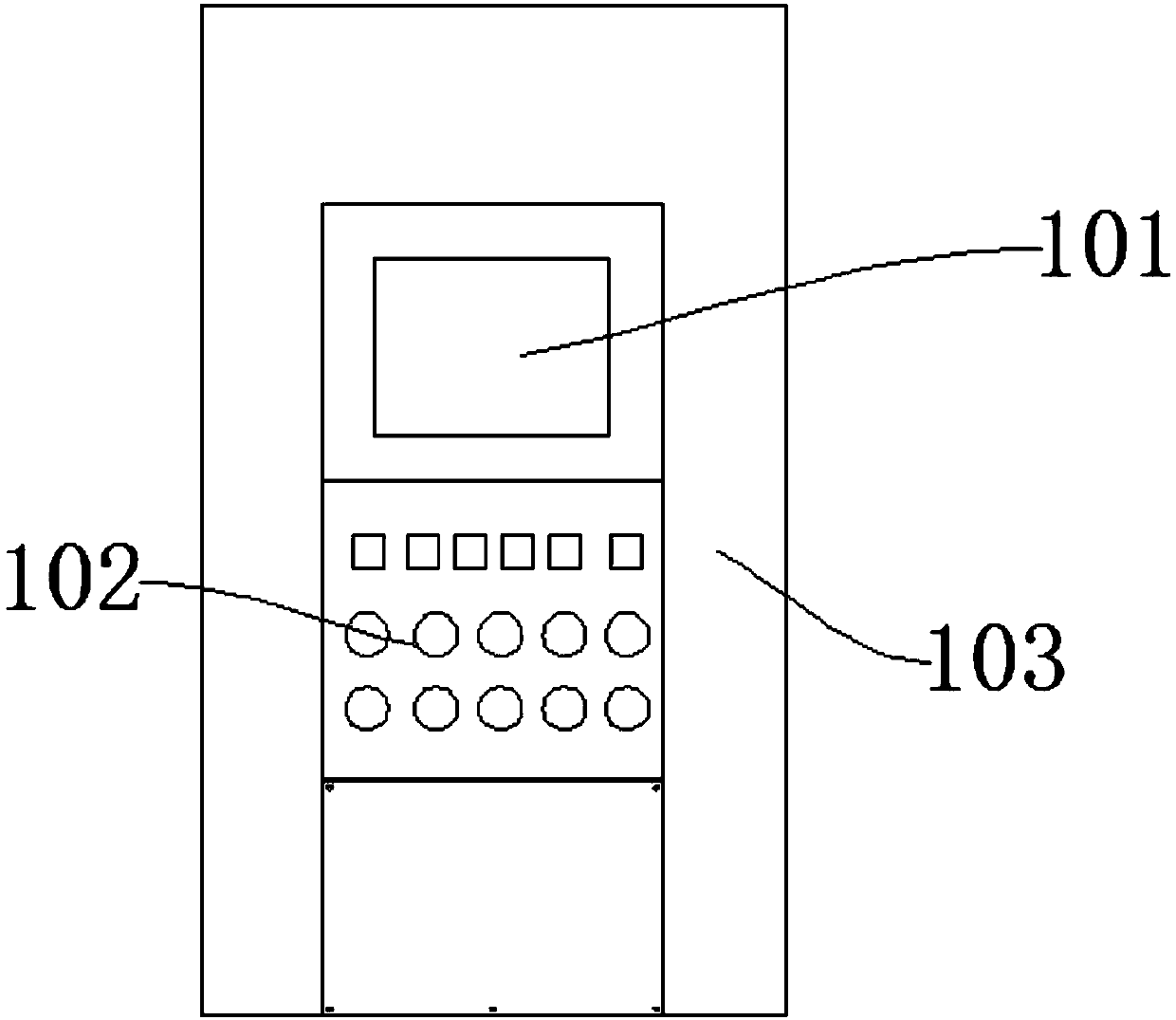

[0021] like Figure 1-Figure 3 As shown, a sickle numerical control punching and cutting device includes a numerical control box 1 and a stamping cutter head 5. The numerical control box 1 is composed of a display 101, function buttons 102 and an electronic board 103. A heavy hammer 4 is arranged above the stamping cutter head 5. The heavy hammer 4 is set inside the slide rail 3, the side of the slide rail 3 is provided with a heat dissipation grid 12, the slide rail 3 is provided on the power box 2, the lamps 6 are provided on both sides of the stamping cutter head 5, and a stamping lamp 6 is provided under the stamping cutter head 5 There are inscription plates 7 and warning signs 11 on both sides of the chamber 8 and the stamping chamber 8 respectively. The bottom of the stamping chamber 8 is provided with a feeding belt 9 , and a fixing seat 10 is provided below the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com