Oil fume extraction device equipped with distribution plate arranged in front of suction opening

A technology for suction holes and oil fume extraction, which is applied to the components of pumping devices for elastic fluids, oil fume removal, and household heating, etc., to achieve the effect of improving separation ability and high separation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

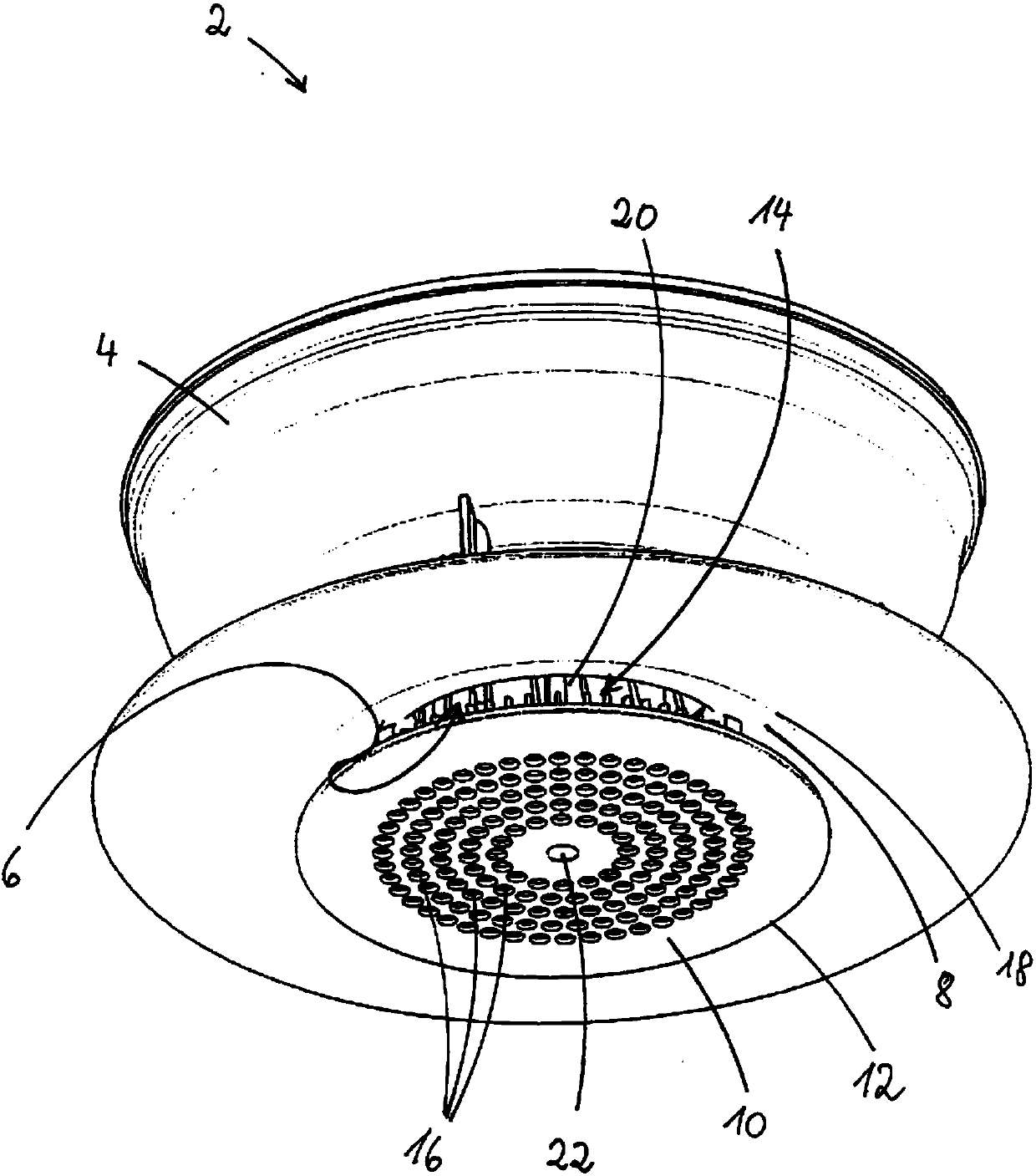

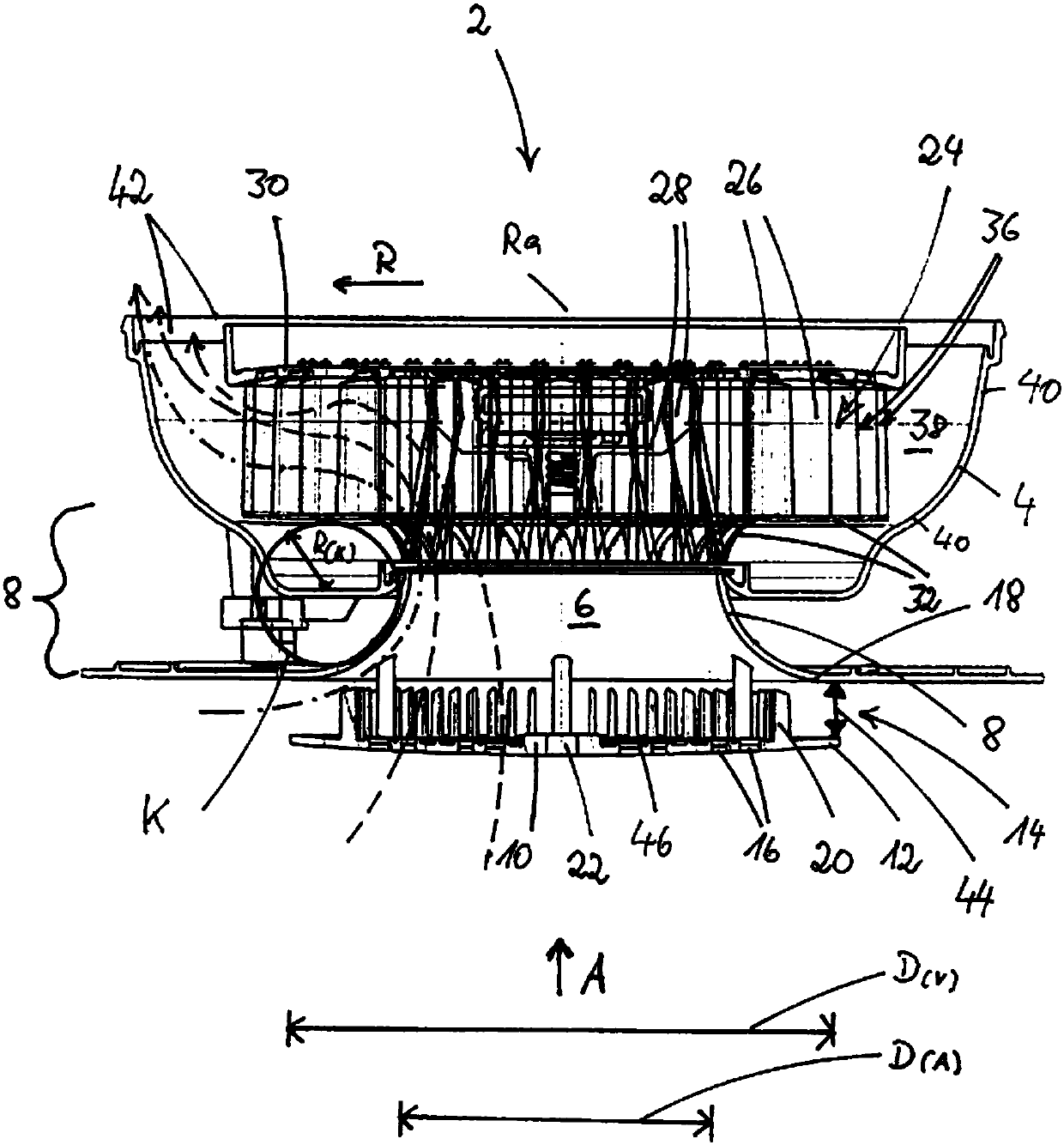

[0025] exist figure 1 The view from obliquely below shows the cooker hood 2 . The range fume extraction device 2 is composed of a housing 4 having a suction hole 6 . The cooker hood 2 is arranged above the cooking zone in such a way that the suction opening 6 faces the cooking zone. The suction opening 6 is surrounded on the peripheral side by an inflow lip 8 . The inflow lip 8 forms an approximately funnel-shaped suction channel on the suction side that narrows in the direction of flow, which continues into the interior of the hood 2 .

[0026] Suction hole 6 in figure 1The view shown in is covered by the distribution plate 10 . In this embodiment, the distribution plate 10 has a circular shape, which also applies to the suction holes 6 . In this embodiment, the distribution plate 10 has a larger diameter than the suction holes 6 , so that the distribution plate 10 with its outer edge 12 extends completely beyond the curvature of the inflow lip 8 in the vertical directio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap